The chemical etching experts

We are world leaders in the development of photochemical technology to produce intricately shaped components through metal etching. Established in 1968, we have built a wealth of knowledge and experience to offer our customers, ensuring they get the best possible solution. We are specialists in chemical etching – also known as chemical milling or photo etching. We have over 55 years of experience chemically etching metals to create precise and intricate components.

For more information on how we can reduce your costs & improve lead time contact our dedicated account managers on 01480 226699 or email enquiries@photofab.co.uk.

What are the benefits of our chemical etching service?

- Fast prototyping

- Rapid 24hr quoting

- Short lead times

- Product Realisation support team

- Large stock of industry standard metals

- Low-cost manufacturing process

- Technically trained dedicated account managers

- Low-cost digital tooling

- Low-cost digital tooling design changes

- Mixed sheet graphic tools for prototypes to full production

- Vast range of metals can be etched

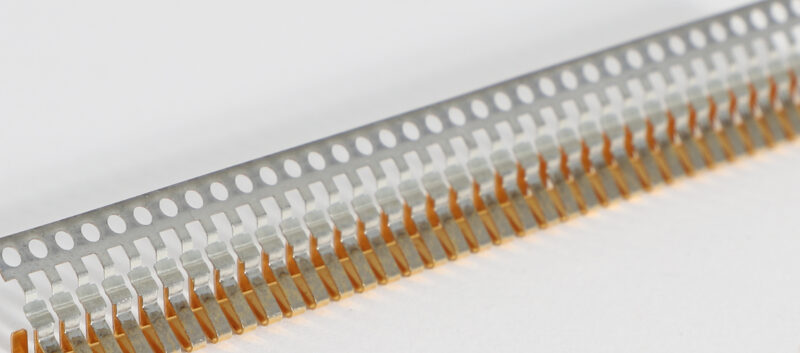

- Etching to Micron accuracy

- Extremely tight tolerances offered

- Half Etched fold lines for tool-free forming

- Half-etched forming to tight tolerances

- Metal properties unaltered by the etching process

- Logos can be etched into flat parts

- Tabbed-in components offered or loose

- No heat or force used in production that could distort parts

- Burr & stress-free process

- Blemish free finish

- As low as 0.010mm sheet thickness up to 1.2mm

- Heat treatment process available to harden metals

- Full hard tool forming service available

- Plating available

- Access to a vast collection of uni form tooling (save thousands and quicken lead times)

- Flat parts available in 24 hours

- Standard rapid service parts ready in 3 working days

- Sample packs available

- Seam Welding and spot welding available

- Quality accredited to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze

- Full manufacturing service and supply chain management

Full service

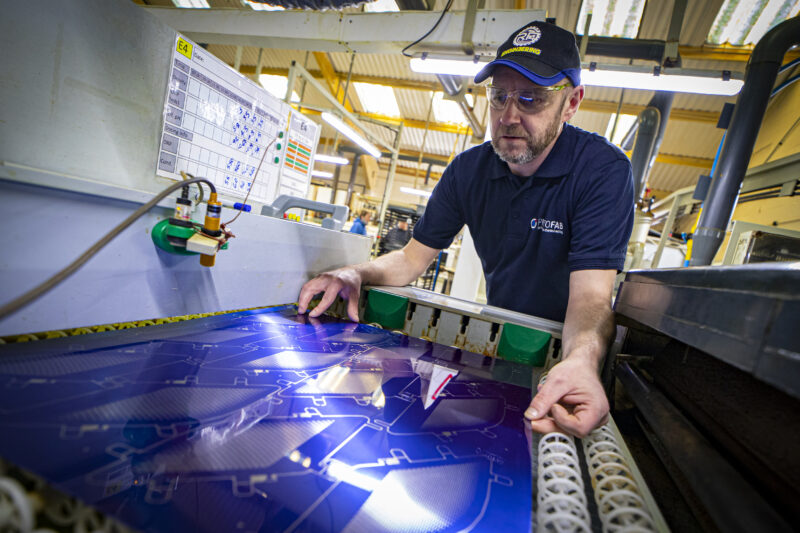

Chemical etching & forming services

From technical advice and digital tooling, through to precision etching, forming, and finishing. This essential set of solutions has been a ‘game changer’ for our customers, not only alleviating supply headaches, but creating a far more efficient process. Our quality managed service ultimately delivers faster with tighter tolerances that ensures less waste and better profitability for our customers.

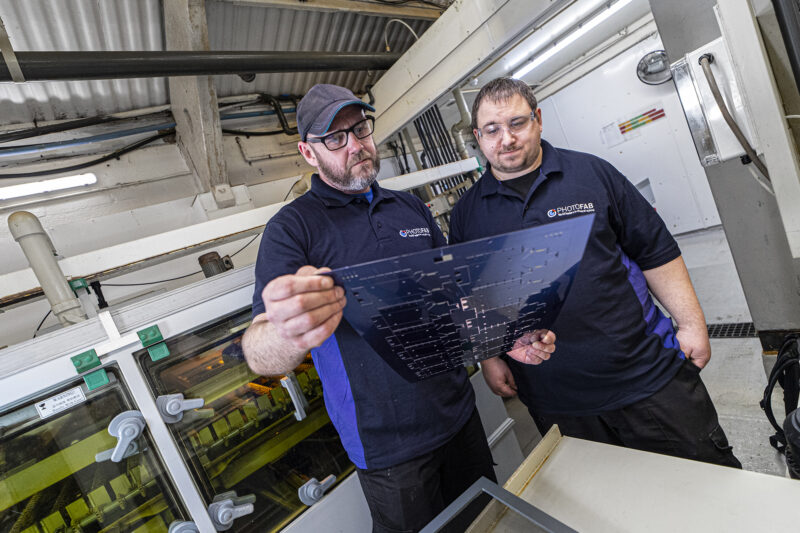

DEDICATED Account Managers

We pride ourselves on the technical quality and high standards of customer service. Every order is assigned to an Account Manager who will be on hand to assist until order completion. It’s this customer-focused service that has led to our high levels of customer retention.

We proudly hold ISO 9001, 14001 and 45001, showcasing our commitment to our service and rigorous quality control, without compromising our environmental standards, We have also been awarded the SC21 Bronze award for six years running, highlighting our commitment to continuous improvement.

Latest News

Batteries and chemical etching

The future of battery manufacturing in the UK.

In a fossil-fuel-less world, the demand for high-performance batteries will continue to multiply. This will cause huge-scale waves in technology innovation for the battery manufacturing industry.

Take a look at other

NEWS updates

To find out how we can help you

Get in touch today