How UK businesses can reshore their whole manufacturing process

Manufacturers based in the UK often outsource their need for precision part components due to cheaper part prices, but at the expense of suffering longer lead times and poor-quality control. However, thanks to a push from the UK Governments, the future of UK manufacturing is looking more likely to be re-shored.

The Conservatives announced a £4.5 billion investment between 2025 to 2030, before being ousted by Labour, and with the current government committing to investing in the critical modernisation of the UK’s industrial infrastructure by 2035, this looks to be an ambitious yet imperative step to reshore UK manufacturing thus keeping supply chains reliable and quality unmatched.

Reshoring a manufacturing process to a UK manufacture can be a seamless transition especially when using a company like Photofab. From starting with an initial consultation to discuss requirements and expectations to trialling our rapid prototyping service, volume flexibility, additional forming services and benefiting from our quality assurances, Photofab will ease customers through the entire process as efficiently as possible. “In today’s fast paced world, reshoring offers a range of benefit that go beyond cost savings, its about building resilience, improving quality, accelerating production times and supporting the local economy” says Nikki Crook (Photofab).

Benefits of reshoring manufacturing to the UK

More Reliable Supply Chains

Offshoring manufacturing processes can leave businesses vulnerable to supply chain disruptions and the fragility of global supply chains is clear for everyone to see. Reshoring manufacturing operations to the UK allows businesses to maintain tighter control over their supply chain. By keeping production closer to home, manufacturers can reduce lead times, remove risks of international shipping delays or unpredictable markets, and improve manufacturing efficiency.

Higher Quality Products

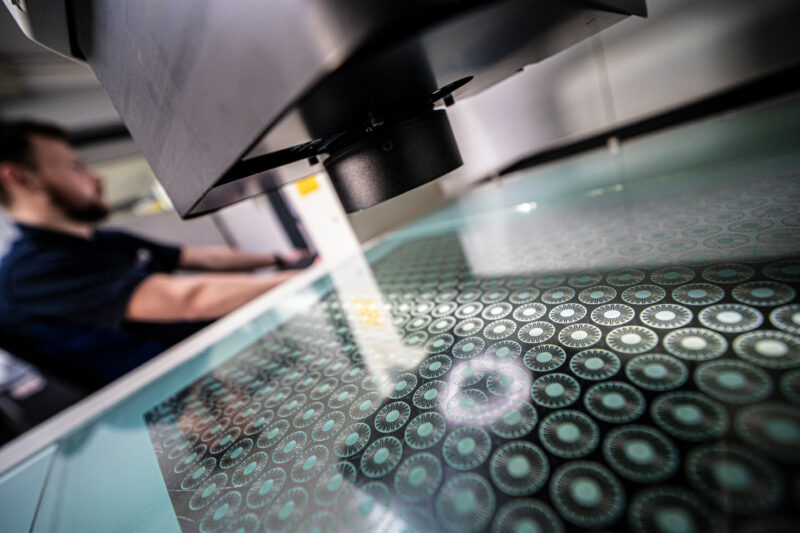

Manufacturers who rely on overseas suppliers can also face challenges around quality control. Reshoring enables businesses to have closer management of their production processes, leading to higher-quality outputs. Precision engineering with chemical etching for example, offers unmatched precision and consistency and durability when manufacturing parts. The UK have clear manufacturing standards, including ISO9001, which must be adhered to and therefore guarantee high quality products are produced.

Read about our successful UK-based precision engineering process.

Faster Turnaround Times

Speed matters in manufacturing, especially in today’s fast paced markets. Processes like chemical etching allow for rapid prototyping and short production cycles. This can be a game changer for industries that rely on rapid prototyping and design changes for small or large production volumes. Faster lead times help bring new products to market sooner and ahead of the competition.

Supporting UK Economy

Reshoring is vital for the UK’s economic growth and for cementing our industrial sector as a global leader. Bringing manufacturing jobs back to the UK can revitalise local communities, create employment opportunities, and spark UK-based industrial innovation.

Reshoring: The Future of UK Manufacturing

With a renewed focus on infrastructure investment within the manufacturing sector, the future looks bright for businesses eager to reshore operations, and for the UK manufacturers ready to step up and support this move.

Get in touch with us today to learn more about the cutting-edge solutions we offer for reshoring success.