Small parts etched for a better future

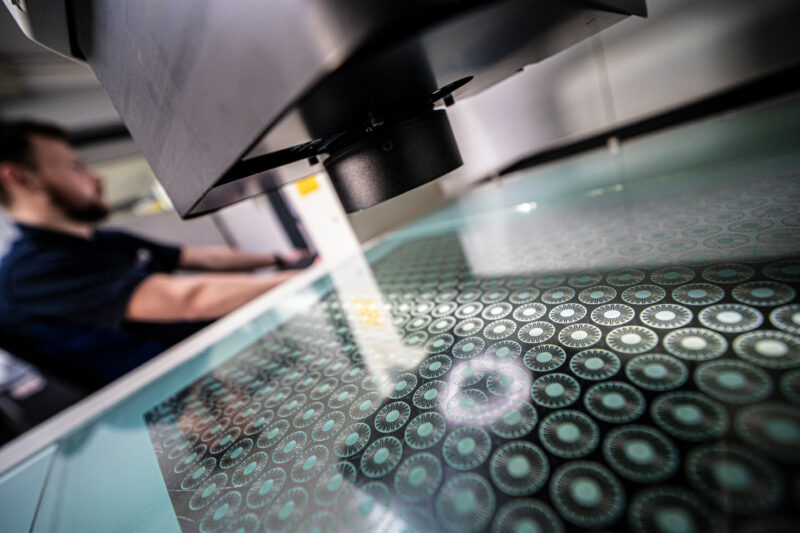

The renewables sector is one of many fast-paced industries that Photofab works with as an established provider of chemically etched components. Photofab’s experience and know-how is depended on by businesses requiring precision components etched in the most dependable materials for any given specification.

The renewables sector has been on an upward trend for years with no signs of standing still. In fact, it will only accelerate quicker as sustainability continues to top the agenda for businesses, the public, and governments alike.

Sustainability requires continuous improvement and flexibility, meaning products and systems are constantly refined to push us towards a greener, smarter future. The associated components need to follow on the same path of improvement and the manufacturers supplying them need to show an agile and flexible approach to production.

What are renewables?

Renewable technologies use natural energy to produce electricity, as opposed to using more common sources such as fuel or coal, which can damage the environment. Sources for renewable energy include:

- Wind

- Wave

- Marine

- Hydro

- Biomass

- Solar

Renewable solutions such as wind and solar power provide environmentally friendly options for the energy industry. With many nations and organisations seeking to cut their carbon footprint by a specific date, or just eradicate it altogether, the renewables sector is an electrifying one for Photofab to be a part of.

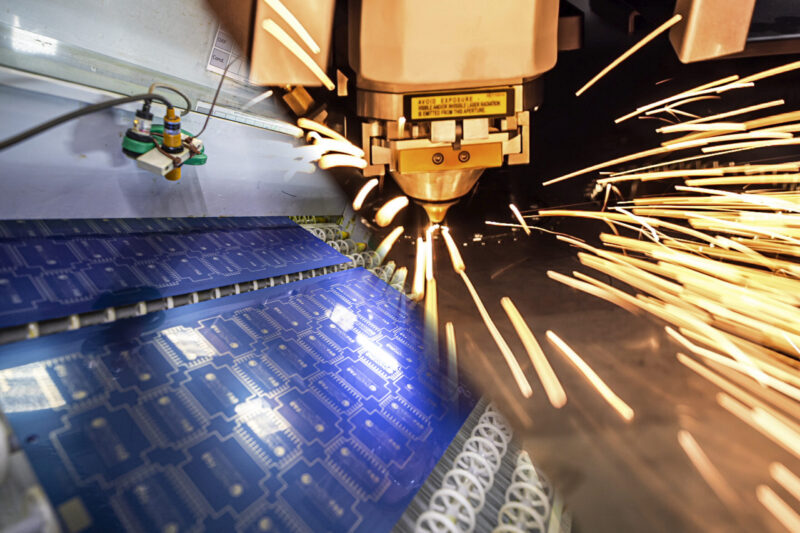

Photofab plays an important role in the manufacturing process, working fast to etch fine and accurate components for a multitude of renewable applications. This is of paramount significance as the industry has become renowned for rapidly refining and redeveloping products, systems, and devices, or introducing new technologies to market.

Some of the areas where Photofab has experience in supplying components for the sector include solar panels and wind turbines. These are both extremely popular alternative energy sources, with the former found on the roofs of many buildings, and the latter scattered across many “wind farms” around the world.

Are fuel cells the way forward?

The list of products Photofab supplies parts for also includes hydrogen fuel cells, which use the chemical energy from hydrogen to generate electricity, heat, and water. An alternative to batteries, they do not run down or need recharging. If hydrogen is supplied, they will continue to produce electricity, heat, or water.

These fuel cells work by passing hydrogen through the anode, which is then split into electrons and protons. The protons pass through the porous electrolyte membrane, while the electrons pass through a circuit, generating an electric current and excess heat. Meanwhile at the cathode, water molecules are produced by combining protons, electrons and oxygen.

We may one day see these reliable fuel cells as the leading power source for road vehicles, with hydrogen replacing petrol and diesel. When using hydrogen as fuel, it only emits heat and water as a by-product, causing no damage to the environment. Hydrogen fuel cells are also far more energy efficient than traditional combustion technologies, using only a fraction of the fuel’s energy compared to a vehicle with a typical combustion engine.

There are many reasons why this reliable fuel source could very well be the future. Multiple worldwide vehicle manufacturers have taken note of this trend and are pioneering the hydrogen fuel cell market, including BMW, General Motors, Mazda, Kia and much more.

Also, with cities around the globe introducing clean-air zones in a bid to reduce emissions, the electrification of transport will also play a key role in a more sustainable future and the components required, such as motor laminations and semi-conductor chips, will ramp up in volume. It will be vital that manufacturers source a component supplier that can match the volume requirements without sacrificing quality.

How does Photofab help?

Regarding fuel cells, Photofab can provide chemically etched plates in a selection of available metals. These can be held to extremely high tolerances, providing smooth finishes and no burrs at all, eliminating expensive and time-consuming deburring from the production process. These plates are also flat and can be stacked, so fuel cell manufacturers have more choice in how they design their products. This flexibility adds another bow to the arrows of chemical etching, and why it is ideal for the renewables sector, in particular fuel cell manufacturers.

This sector moves so quickly with new developments, new ideas and new technologies that Photofab must match the speed, which is why being able to supply fully manufactured prototype parts on short lead times is extremely important. With low development costs, low-cost tooling and a flexible process, the advantages are an ideal fit for the industry’s needs.

Once a prototype design is fixed, Photofab moves into volume production and its strengths in quality and reliability shine through. Photofab holds the very latest quality and environmental ISO standards, demonstrating a commitment to rigorous product quality standards as well as upholding its environmental commitments.

With over 50 years of experience, Photofab is using everything it has learnt to help businesses in the renewables sector build for a better, more sustainable future. This experience, alongside a dedication to customer service with the implementation of a project-specific account manager, allows companies in the sector to tap into a pool of etching expertise throughout the entire project.

To engage with Photofab on your next project and benefit from reduced lead times and costs, a rapid prototyping service and decades of industry know-how, use the contact page to tell Photofab what you need and see just how quickly the team respond!

For more stories like this one, follow Photofab on LinkedIn and Twitter.