Time to reshore your manufacturing supply chain

Our country has faced many challenges in recent times causing a crippling domino effect of disruptions in the supply chain, forcing longer lead-times and reduced profit margins. Reshoring manufacturing services in Britain can help alleviate many of these issues. By outsourcing material handling, supply chain management and full-service manufacturing to UK businesses we can start improving service reliability, turnaround and most importantly, profit margins.

Building on our 50 years’ experience and continuous investment in people, technology, and processes, we have evolved our core metal etching business to offer a full manufacturing service. From design, metal etching and forming, through to value added services, all managed in-house by our dedicated account management team. This provides industry leading standards in both quality and turnaround.

A dedicated partnership of support

Our capabilities and automation have created an industry leading standard in all levels of production from prototyping to high volumes. The Photofab service is led by its people, with good old-fashioned customer service, technical knowledge, and expertise.

From initial contact, you will have your own dedicated account manager, who will help advise you and suggest the most efficient processes for your project and can quote within 24 hours. Once the project and timescales have been agreed, it will be added to our ERP (Enterprise Resource Planning) system to monitor and control order progression. Quality control checks are made at every stage to ensure our high standards are met and strict tolerance control is maintained throughout.

Etching a better service

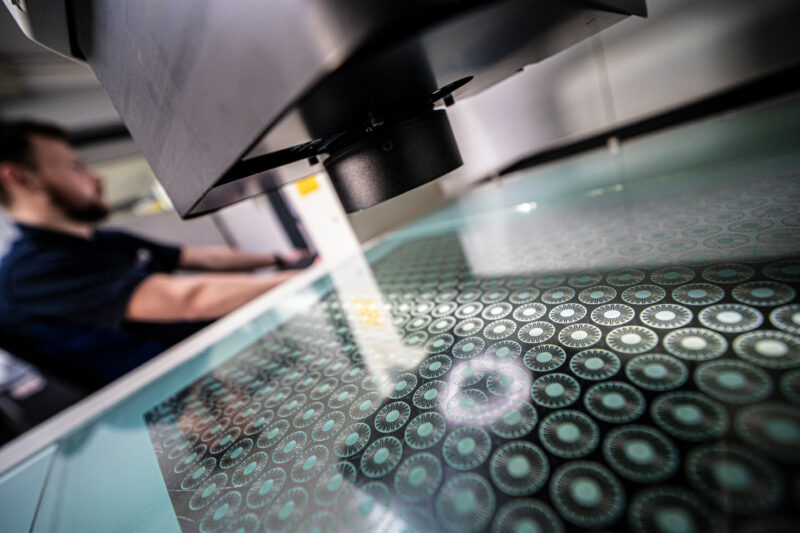

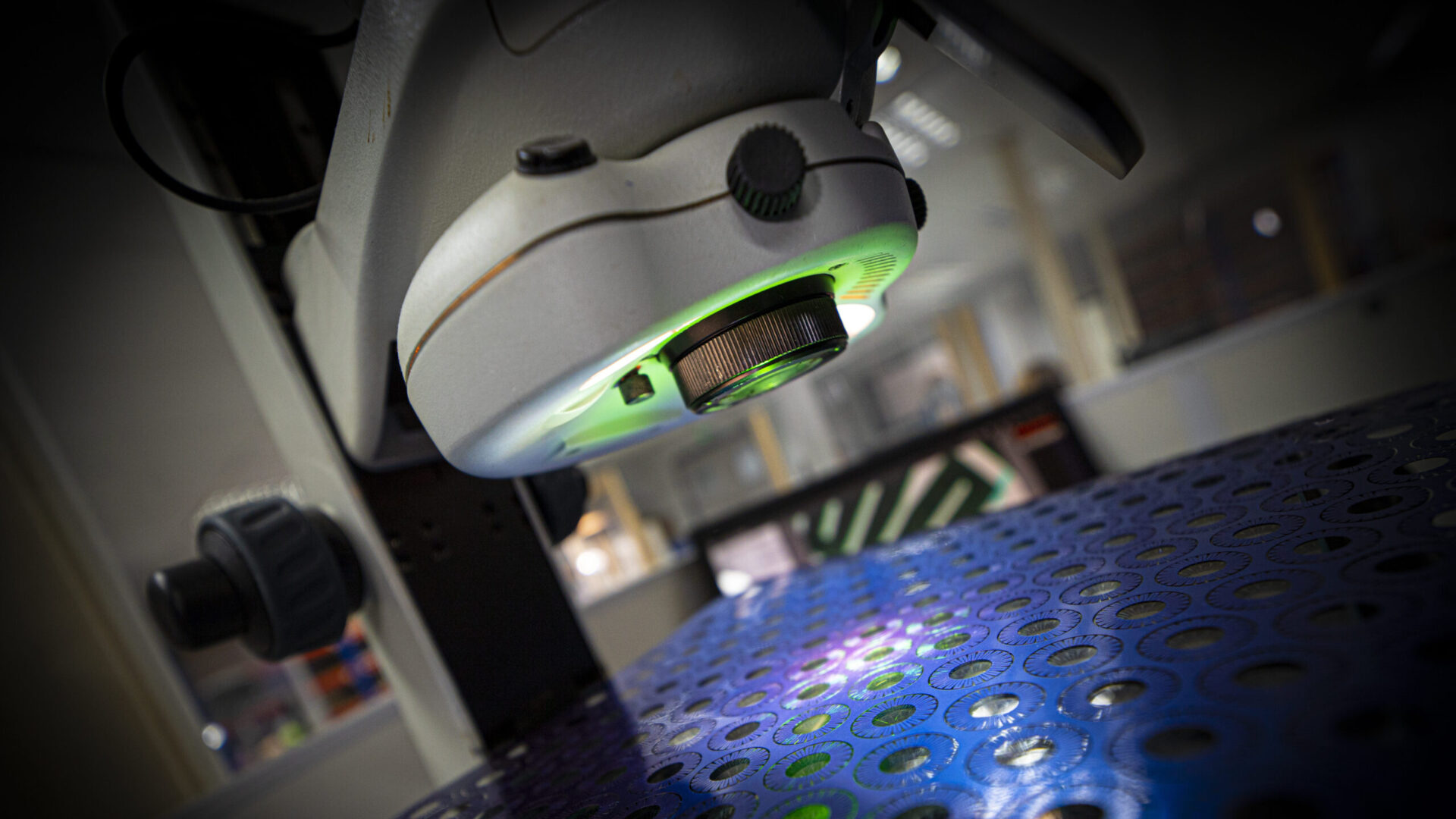

Providing the best possible service using the most efficient processes are at the heart of everything we do at Photofab. Starting with our automated plotter, which produces fast and accurate digital tooling in just 30 minutes. Remote digital files can be sent direct, making it highly cost-effective and fast to make any design changes.

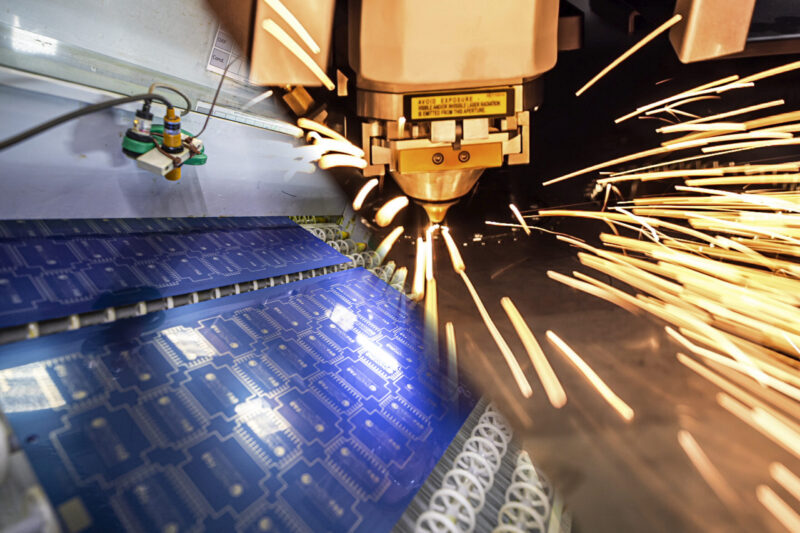

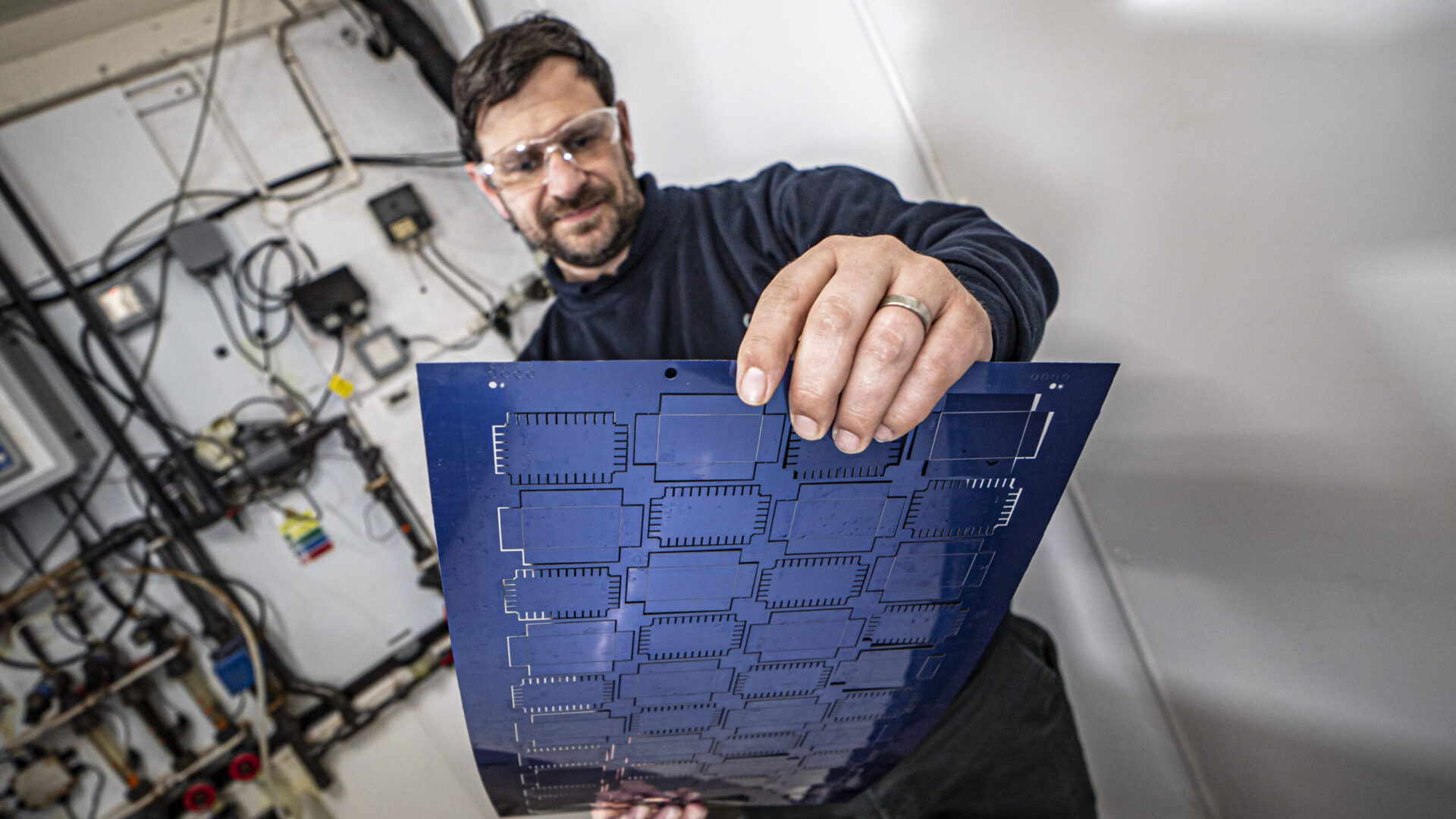

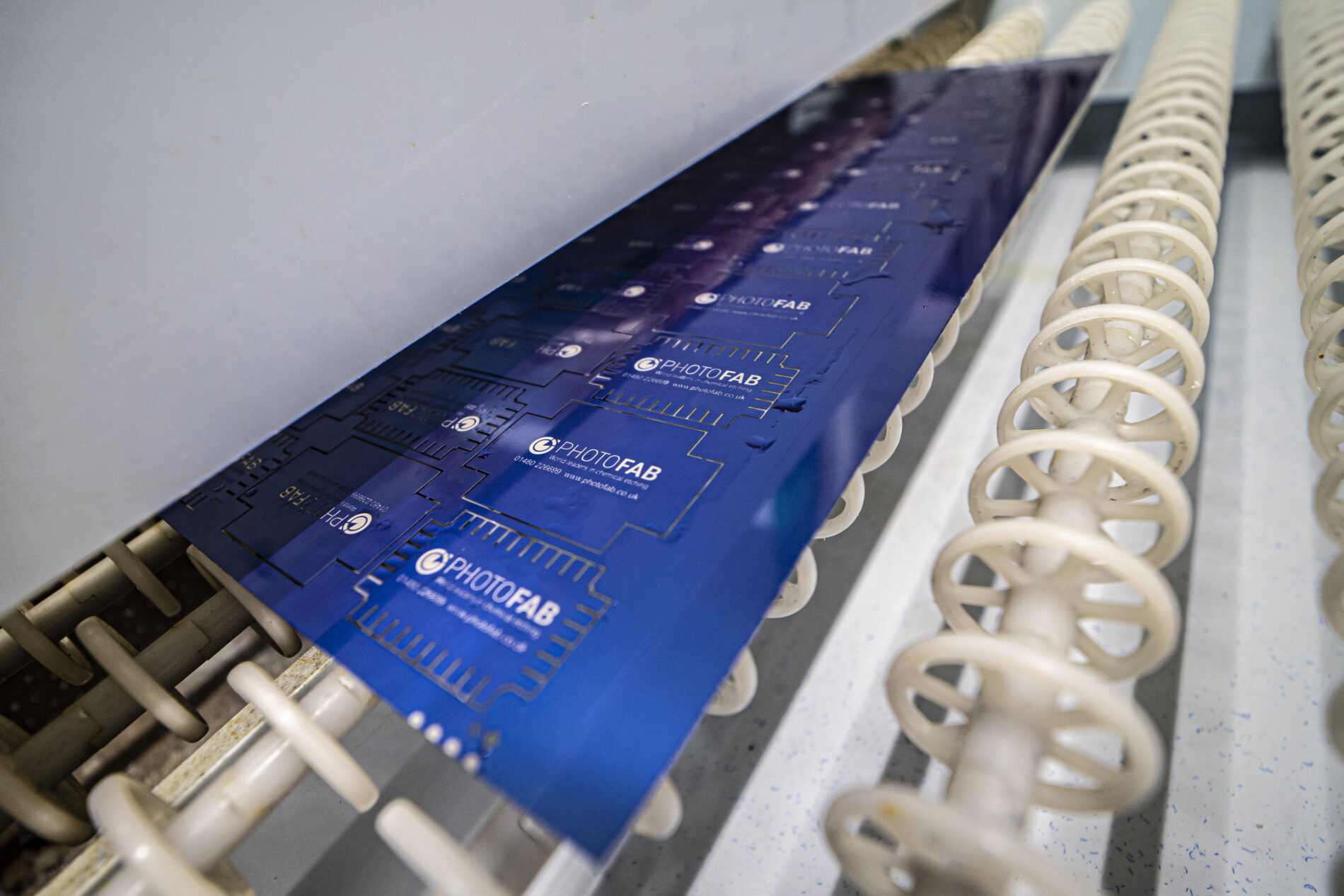

Orders are sent through to our in-house materials department, where our fully traceable materials are picked, prepared, and printed, ready for the etching process. Our chemical etching department houses five etching machines, all with multi-chamber etching capabilities for faster etching on thicker materials. This is all supported by our production team, who are highly experienced.

Investments in automation have increased our capabilities in metal stripping, measurement, and logistics. This has allowed orders for forming, assembly and finishing to be completed faster, maintaining our 98% On Time Delivery service.

On form to shape your future

Photofab have recently opened a new dedicated engineering unit, the aim of this is to offer an even greater service and flexibility to our customers. Along with 100’s of stock universal tooling and capabilities for custom tooling, including custom multi-slide tooling for specialist radial forming. This is backed up by a highly trained team and a multitude of presses. Photofab have also invested in a new high impact press for forming thicker metals.

To support our world leading etching division, Photofab can now offer toolroom, forming and finishing as part of our full-service offer or as a stand-alone service. Customers can now enjoy the flexibility of enjoying the convenience of full-service manufacture or pick and choose services to suit them.

Value added partnerships

Photofab also have long working relationships with specialist partners for additional finishing services. These services can range from laser-cutting, plating, anodising and heat treatments which can add decorative finishes, prevent corrosion, and further improve durability.

All additional processes are managed closely and delivered with full transparency and traceability.

The critical ingredients; Quality, Cost and Speed

Our processes follow SC21, ISO9001, 14001 & 45001 with full traceability along the way. Coupled with our manufacturing efficiencies and automation, customers get the best of both worlds. From short run formed prototyping to high volumes with a 98% On Time Delivery track record, we aim to exceed your expectations.

Call our account team today on 01480 226699 or contact us now to see how Photofab can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn and Twitter.