Being sure about reshoring

Now more than ever, the UK has begun to appreciate the importance of its homegrown manufacturing base and talent. Following the covid-19 lockdown, there have been several rallying calls from industry leaders to get UK manufacturing back on its feet and encourage spending. Reshoring and alleviating the sector’s short-term supply chain pains could be a critical facet of delivering an upturn.

Reshoring involves returning the production and manufacturing of goods back to the company’s original country. In turn, the company’s returned and now increased home-based production would benefit its domestic economy and its fellow manufacturers too.

The manufacturing community’s refocus on reshoring may have come about on the back of a global pandemic, but these recent events emphasise the significance manufacturing has on the country and how it should never be undervalued or under-supported.

A coming together at home

In a recent survey undertaken by The Engineer, participants were asked if they thought the pandemic would lead to reshoring of UK manufacturing: 91% felt that reshoring was necessary in one way or another.

With many SMEs remaining operational during lockdown, the UK has been able to fight back against the pandemic with the quick and effective manufacturing of personal protective equipment (PPE), ventilators, and critical equipment. The response has been inspirational, and the positivity is amplified by the continued efforts of the community – a feeling that UK manufacturers won’t be keen to lose any time soon.

Offshoring has proven effective in the past, but there is a much greater focus on mitigating risks in supply chains since the impact lockdown has had on the movement of critical components, materials and products. There is also rising labour costs in traditionally low-cost countries so there is more than one good reason to think twice about whether sending manufacturing disciplines overseas is the right tactical move.

In recent years, there has also been a worldwide push towards reducing impact on the environment; with less overseas travel involved with keeping supply chains and operations closer to home, there will be a reduction in carbon emissions, while domestic travel will also result in shorter lead times.

UKMfgUnite

One great example of localised manufacturing collaboration is the formation of UKMfgUnite. Run by manufacturers for manufacturers, UKMfgUnite members want to bring the manufacturing community together to alleviate short-term pains brought on by the pandemic, but also have one eye on the future of UK manufacturing. Photofab is proud to be an active member and encourages any UK manufacturer to sign up and start collaborating with like-minded businesses.

If we can’t rely on the strength of our domestic businesses, how else will the UK economy recover? This is why the importance of UKMfgUnite cannot be understated. A collaborative effort from over 220 UK manufacturers has already proven that businesses working together can benefit not only each company, but also the UK economy and its people.

How has Photofab helped?

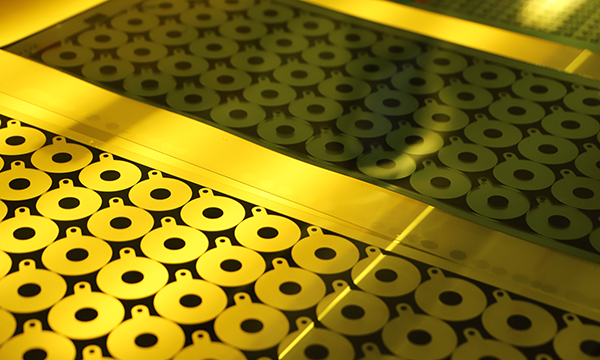

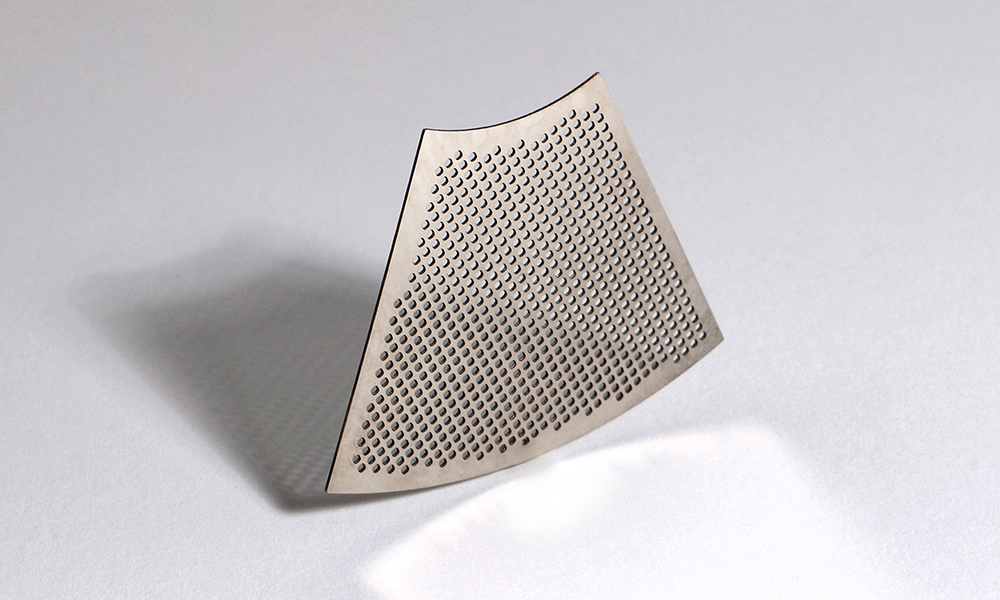

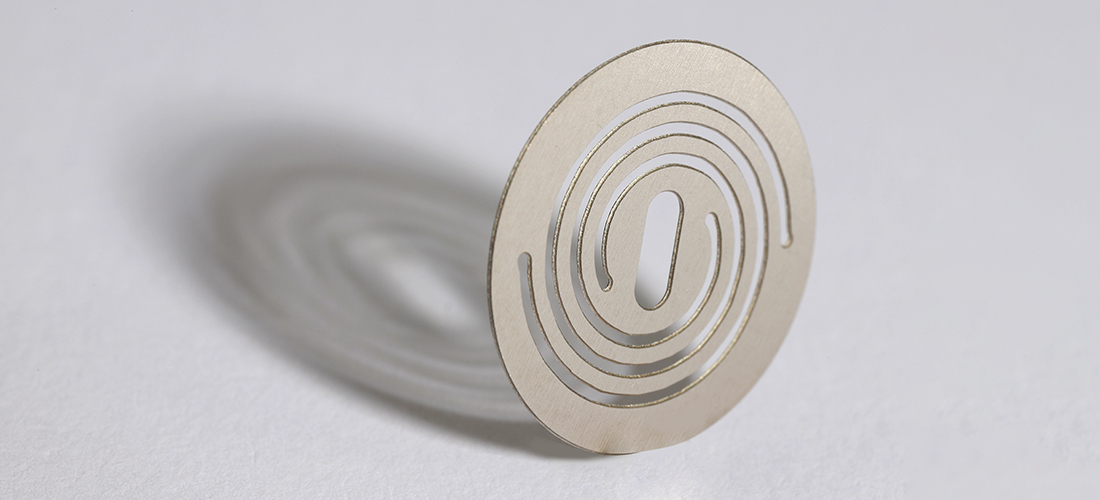

Our regular manufacturing processes are all undertaken in the UK, so we are always championing UK manufacturing and contributing to the economy. Since lockdown, we have also provided manufacturing support for the medical sector, and supplied critical support for Covid-19 tube scanners. As mentioned previously, we are also playing our part in the UKMfgUnite initiative, and we encourage UK manufacturers to do the same and become a ‘collaborationeer’, or to ask for help if necessary.

Our tiny, precise components help make much bigger machines work, and are part of a number of critical pieces. You wouldn’t want to have to wait a significant amount of time for our intricately shaped components, which is one of many reasons we keep all of our manufacturing close to home.

If you need a trusted partner for the supply of critical components, manufactured to the highest standards in as little as 24 hours, contact one of our experts today on 01480 226699. Follow us on LinkedIn and Twitter for the latest information.