Chemical etching proves the most fit for purpose technique in the development of components for new products

Delivering new products to market will often be a complex process of activities, and particularly in markets such as electronics, renewable energy, and medical where Photofab hold extensive experience.

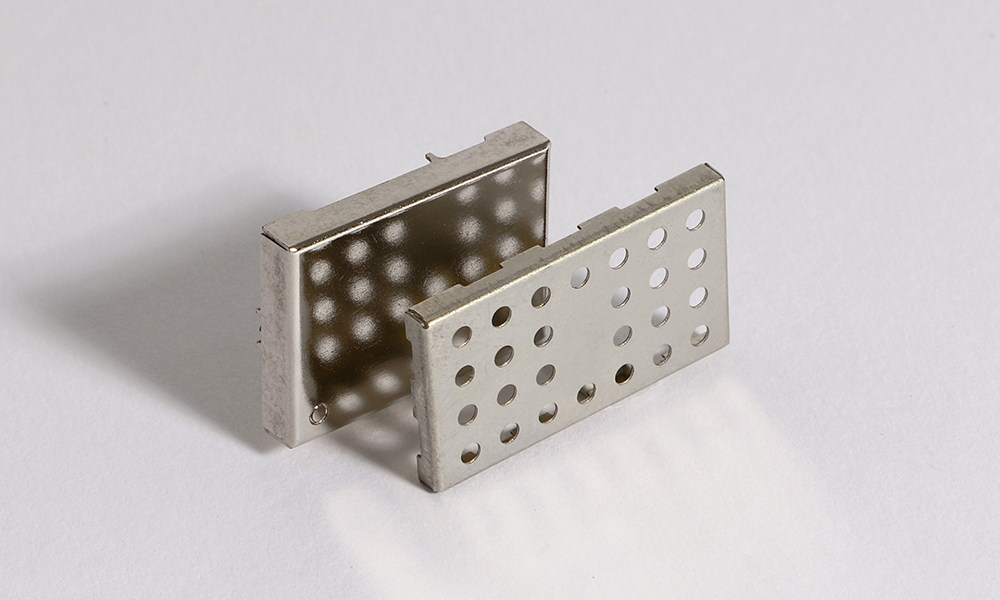

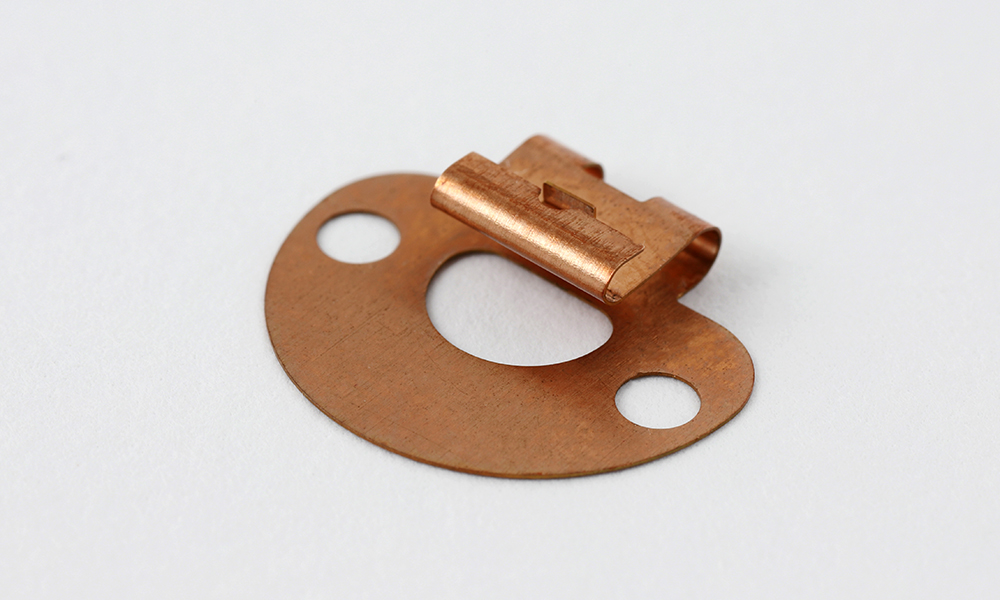

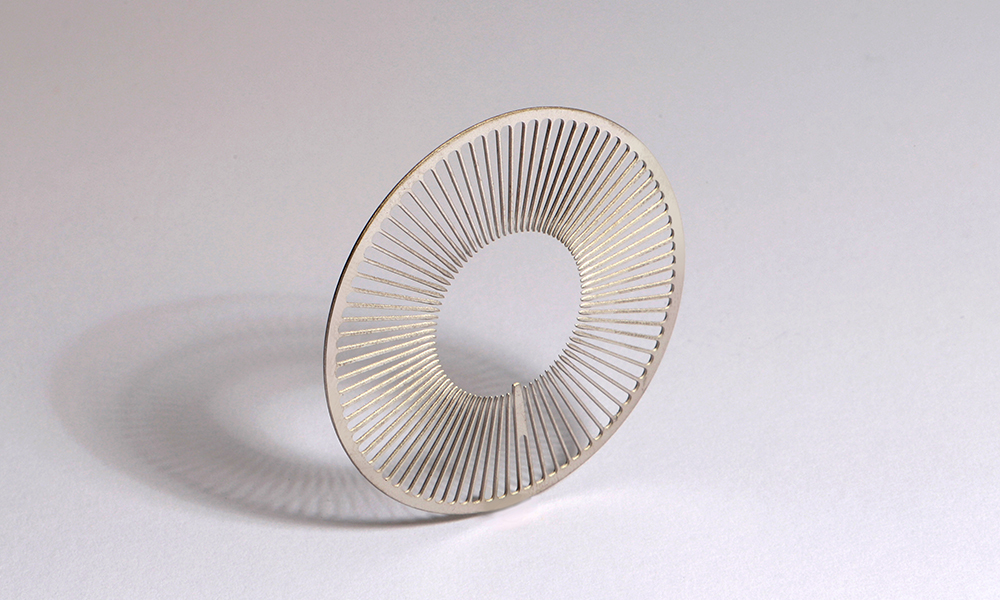

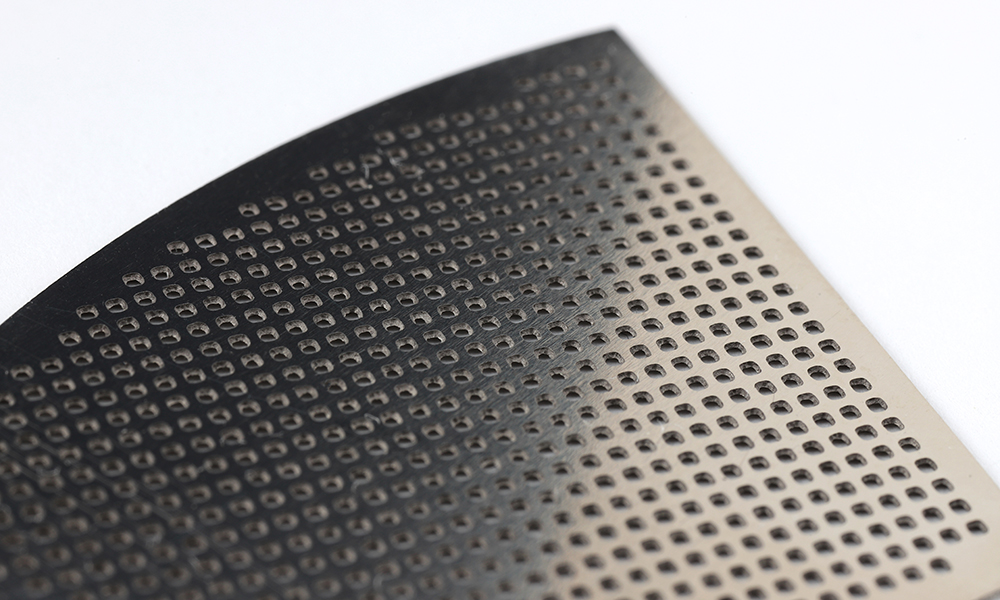

Photofab is relatively low down in the supply chain when businesses undertake the development of new products but that shouldn’t deflect from the important role that small metal components play in the overall scheme. These components which can be extremely diverse depending on the project can vary from battery contacts and connectors to gaskets and complex diaphragms and their well-considered development from an initial design concept can be the difference between getting to the phase of implementation quickly or not at all.

Before Photofab’s involvement in the development of new products comes a stringent design process by which specifications for component prototypes are conceived. At this point, businesses will be instructing component manufacturers like Photofab to develop prototypes to ensure wider systems, devices and products can become viable marketable solutions.

The prototyping phase and the skill of agility

When businesses are undergoing this phase of product development, they are looking to experts for guidance on several component considerations such as relevant material selection and its full traceability, surface finish, and the ability to ramp up volume with a cost-effective answer to production methods.

It is important to note that more often than not, despite the stringent design processes underpinning new product development, when it comes to component requirements, those designs can shift and differ during the prototyping phase.

This is where agility becomes vital. Changes in component design can be consistent and the technique of chemical etching delivers the necessary flexibility. Capabilities unique to the process such as the creation of electronically generated files can be used to develop photo-tools which are transferred to the surface of the metal. These files can be updated with ease and are capable of including various component designs of the same thickness on a single metal sheet.

When every design adjustment results in a new prototype, this capability ensures that businesses not only get new prototype iterations fast but at a substantially lower cost when comparing the capabilities of alternative metal working processes that would require much lengthier mechanical tooling adjustments. Over the years, this service has become a core competency and is one of the many reasons Photofab can promise a 24-hour rapid turnaround solution.

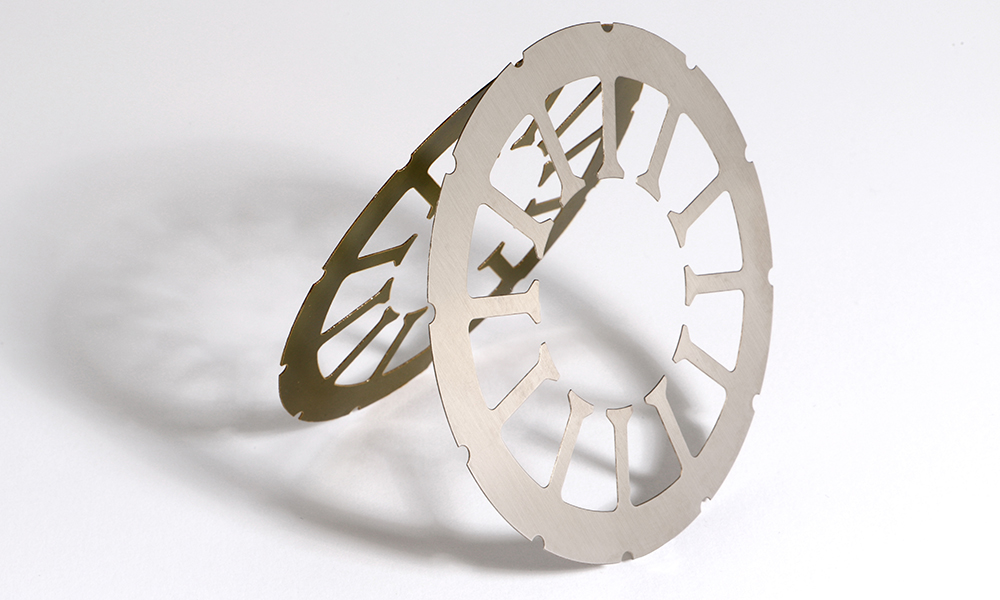

Alongside its chemical etching capability and associated photo-tooling, Photofab has also developed an extensive pool of universal form tooling. This becomes a viable solution for businesses looking for small adjustments to more standard parts such as shims, flat springs, and encoder discs.

Nail the prototype, ramp up the volume

On agreement of the final formed component and its tested prototype, businesses will be keen to move into the next phase of product development and the process by which to take a prototype to volume production.

There is no minimum or maximum quantity within Photofab’s range meaning it can appease initial prototyping requirements and one-offs but also large volume production quantities. Providing the ability to keep the manufacture of components from prototype to volume production under one roof has become a critical added value benefit to the customer, with them becoming assured of Photofab’s manufacturing competencies during the prototyping phase.

These assurances are testament to the 50+ years of industry experience producing intricately shaped components spanning almost every industry sector, and with the instruction of volume production, this engineering experience is at the customer’s disposal throughout the lifetime of the project.

Photofab prides itself on customer service with every customer benefitting from a dedicated account manager alongside the engineering advice often utilised to see through more economical manufacturing and cost saving measures.

Contact Photofab with confidence

Hopefully, the information provided here shines a light on the vital role small components play in the development of new products but particularly how chemical etching as a technique in the manufacture of those components offers numerous benefits.

When it comes to component prototyping for new product development projects, chemical etching is a no-brainer!

To engage with Photofab on your next project and benefit from reduced lead times and costs, a rapid prototyping service and decades of industry know-how, use the contact page to share your requirements and see just how quickly the team respond!