Driving Renewables Forward with Chemical Etching

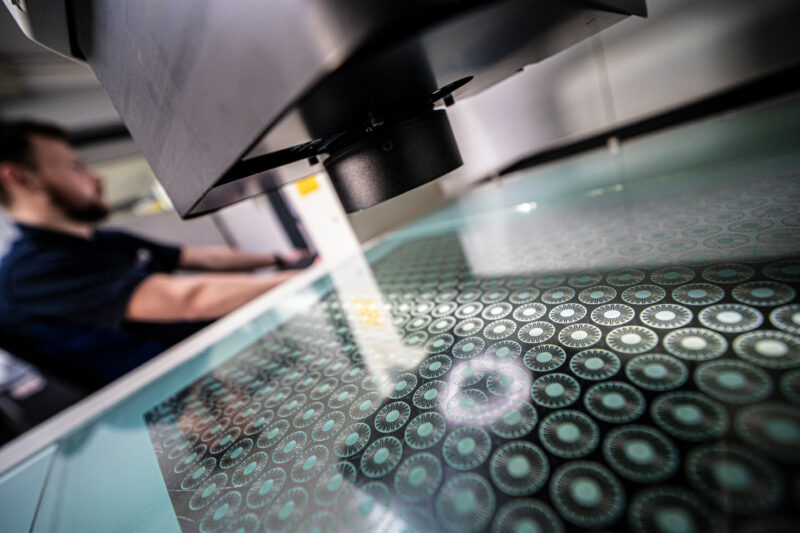

As the renewable energy sector rapidly scales up to meet crucial sustainability goals, specialised manufacturing processes are required to produce the intricate mechanical components at the heart of solar panels, wind turbines, hydroelectric generators and other renewable technologies. This is where Photofab’s expertise in chemical etching proves invaluable.

Precision like no other

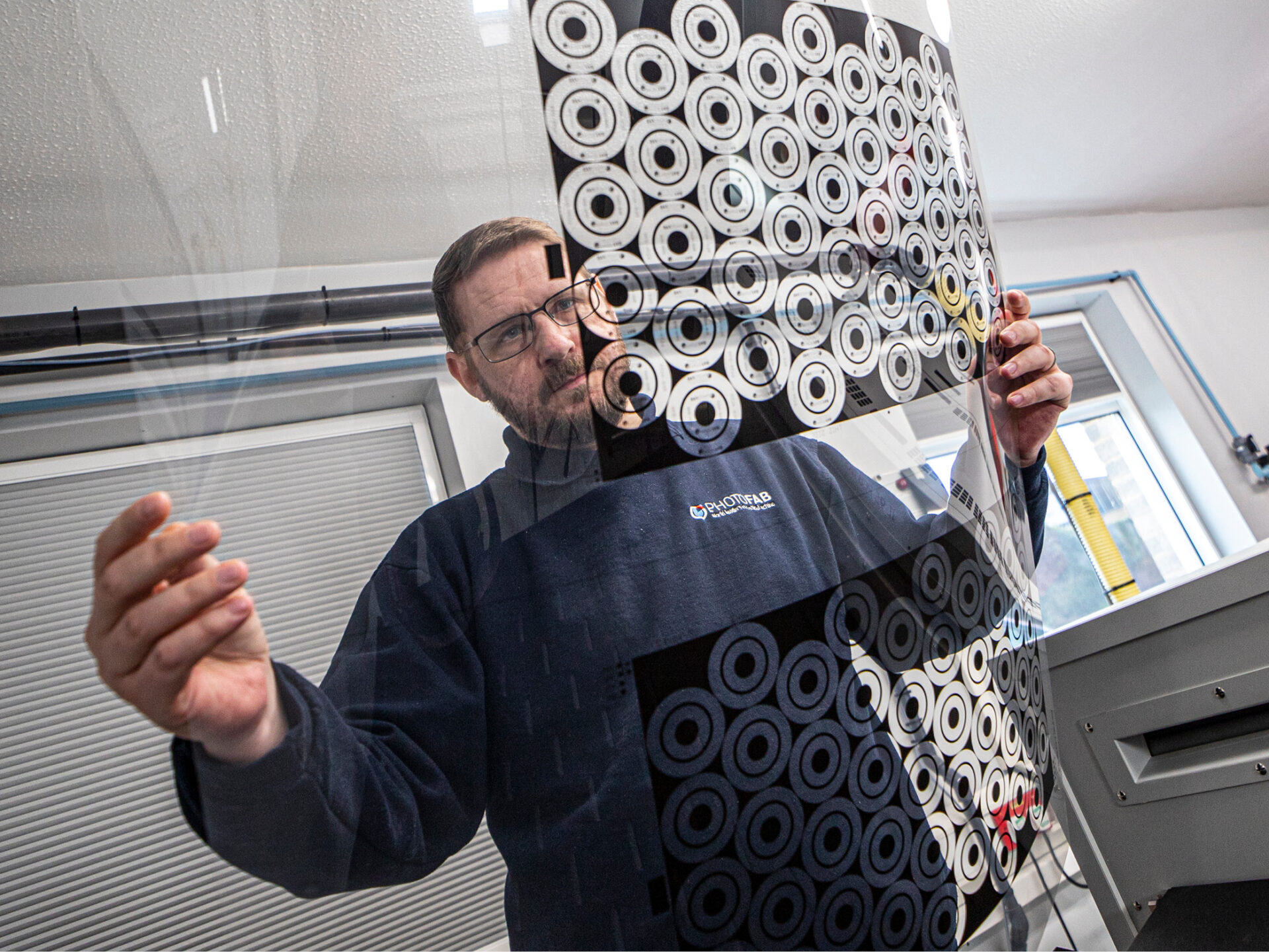

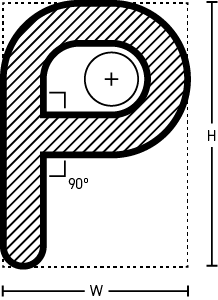

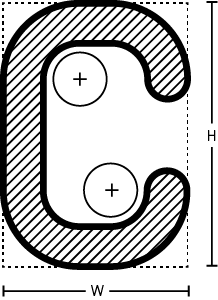

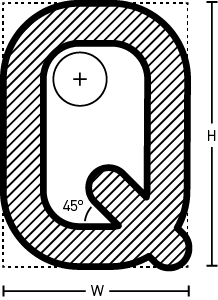

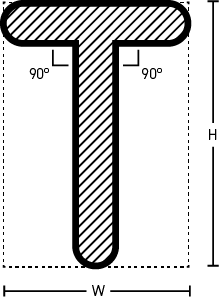

Chemical etching is the ideal manufacturing process for renewable energy applications. Extremely high precision, thermal stability, corrosion resistance and minimal burrs are essential. The etching process yields components with remarkable accuracy and consistency thanks to Photofab’s state-of-the-art process and expert staff. Parts can be etched to incredibly tight tolerances – up to 0.025mm with thicknesses ranging from 0.01-1.25mm. We have previously worked to produce a wide range of components that power renewables and are highly experienced in this sector.

Sustainable and efficient

As an environmentally responsible production technique with low waste, chemical etching aligns perfectly with the sustainability goals of the renewable energy industry. As well as this benefit, we can offer rapid turnaround times, including 24-hour service for flat components. We are here to deliver rapidly when the renewable sector needs it. Renewables customers also benefit from our wide range of in-house engineering services for toolroom, forming and finishing needs. We also offer a full service, including prototyping and scaling up to scale manufacturing.

SPEED

PRECISION

COST-EFFECTIVE

Typical applications in the renewable energy sector:

- Fuel cell and bipolar plates.

- Heat exchanger components.

- Shims and spacers.

- Meshes, filters, screens, and grids.

- Gaskets and seals.

- Formed and flat springs.

Trusted for decades to deliver.

With over 55 years of expertise producing highly intricate etched parts across a variety of industries, we have built a reputation over the years as the ideal partner for etching, thanks in no small part to our customer-focused service. For the renewable sector, our parts can be found in fuel cells, heat exchangers, filters, seals, and many other renewable technologies.

When precision, consistency and environmental responsibility are vital requirements, renewable energy companies and suppliers can trust us to deliver.

What materials can be etched?

We offer an extensive range of metal types and thicknesses, all with full traceability. Various hardness are also offered to meet your requirements. Metal stocks are kept at levels that enable us to offer rapid service to meet the needs of this fact paced industry.

Stainless Steels

Austenitic (301, 302, 304, 316, S526, S527), Martensitic (321, 410, 420), Precipitation Hardened (17/7), Heat Resisting (309, 310)

Other Steels

Mild Steel, Carbon Steel, Tool Steel, Spring Steel, Transil, Losil.

Nickel Alloys

Nichrome, Mu Metal, Nickel Copper (70/30), Inconel, Nickel Brazing Foil.

Nickel/Iron Alloys

Invar, Alloy 42, Kovar, Radio Metal.

Copper

Tough Pitch 101, Oxygen free – High Conductivity.

Copper Alloys

Brass, Phosphor Bronze, Beryllium Copper, Nickel Silver, Ferry Constantan.

Aluminium and Aluminium Alloys

Silver and Alloys

Silver, Silver Alloys, Silver/Copper, Silver/Palladium, Silver Brazing Alloys.

Why work with Photofab?

We are renowned for their industry leading customer service, where our dedicated account managers are your expert single point of contact. Supporting you with anything from technical and design questions through to quotes, orders, delivery, and everything in between. We strive to offer the best customer service experience in the industry. We take immense pride in being able to push the boundaries of chemical etching with our commitment to continuous improvement.

KNOWLEDGE

Over 55 years of expertise and experience with a highly trained team of specialists delivering high volume orders.

CAPACITY & SPEED

For cost-effective full volume orders of hundreds of thousands. We also offer fast turn-around, as little as 24 hours.

SERVICE

Our dedicated account managers are experts and there to help, advise and manage.

RELIABILITY

Trusted by thousands of OEMs to deliver quickly and accurately.

QUALITY

SC21, ISO 9001, 14001 & 45001 quality processes.

TRACEABILITY

Fully traceable materials and processes.

Transform Renewables with us

If you are looking to find a manufacturing partner for your renewables project, look no further than us. Our team of dedicated Account Managers will work closely with you throughout the entire process. They act as a single point of contact for your order, ensuring personal and reliable service. Find out why we enjoy such high customer retention by working with us!

You can also follow us on LinkedIn for more updates.

To find out how we can help you