Empowering Aerospace and Space Innovation with our Chemical Etching Expertise

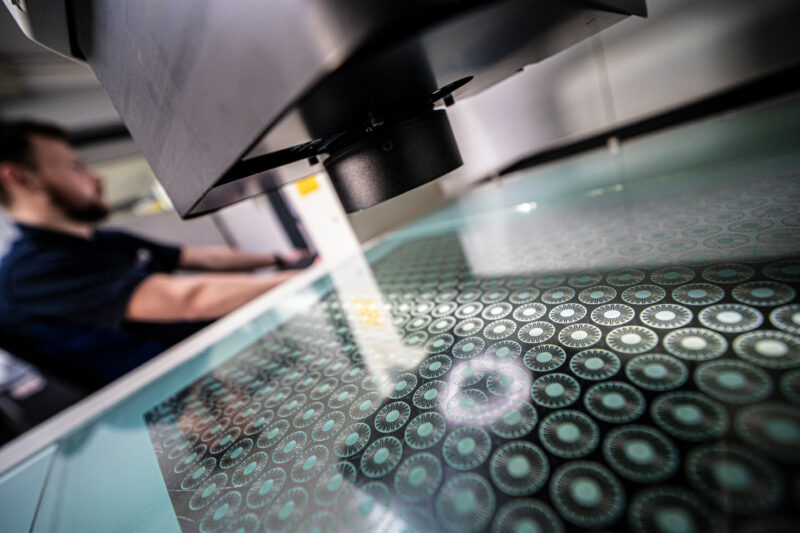

We have a long-standing history of meeting the needs of respected companies in the aerospace and space industries. Our expertise lies in the precise chemical etching process, which we use to create essential components for aerospace and space exploration projects.

In these industries, reliability and performance are crucial. That’s why the chemical etching process stands out as a superior choice. Our skilled material handling team ensures that each component meets rigorous quality standards. We pay close attention to detail, ensuring that materials are traceable and conform to precise grades and specifications. This results in flawless parts that are free from stress, burrs, or distortion – essential qualities for the demanding aerospace and space environments.

The Evolution of the Space Industry

The space industry is experiencing significant growth, driven by increased investment from governments, private entities, and international collaborations. This surge in interest is primarily directed towards advancements in launch systems, satellite technology, and commercial spaceflight services. Companies such as SpaceX, Blue Origin, and Virgin Galactic are at the forefront, pioneering suborbital flights, orbital tourism, and lunar exploration.

We understand the importance of our role in supporting this evolving industry. Our expertise in chemical etching allows us to efficiently manufacture components vital for spacecraft, satellites, launch vehicles, and other space applications. Whether it’s producing intricate parts with precision or ensuring materials meet the rigorous standards of space environments, our commitment to quality remains steadfast.

As investment in space technology continues to rise, we are dedicated to driving innovation, facilitating space exploration, and creating opportunities for commercial activities beyond Earth’s atmosphere.

Trusted to Deliver Excellence

In aerospace and space industries, reliability is paramount. We prioritise excellence through meticulous attention to detail, ensuring full traceability, documented process control, timely deliveries, and consistent quality. Chemical etching is integral to our process, offering cost-effectiveness and precision in handling complex geometries with minimal burrs and distortions.

Our expertise extends to various metals, including steel, stainless steel, aluminium, copper alloys, and nickel alloys. Our portfolio features a diverse range of components, from actuators to terminals, all crafted with precision to meet the rigorous standards of the aerospace and space sectors.

Committed to Continuous Innovation

Chemical etching isn’t just about precision; it’s about consistency. With five multi-chamber etching machines, we provide efficient and accurate etching services for various metals. Our experienced production team ensures that we meet the rigorous demands of critical industries effortlessly.

In a constantly changing landscape, staying proactive is essential. We prioritise continuous improvement. Whether it’s adjusting to new regulations or pushing the boundaries of innovation, we are committed to excellence. Let’s collaborate to find solutions that cater to your evolving needs in these dynamic sectors.

The Advantages of Chemical Etching for Aerospace and Space

- Burr-free and stress-free manufacturing

- Strong, lightweight components manufactured.

- Exceptional temperature and corrosion resistance

- Intricate and complex geometries

- Micro scales of components available

- Flexibility and customisation

- From single-piece prototypes to high-volume production

- Fully traceability

- Cost-effective tooling and manufacturing processes

- Rapid turnaround times, as fast as 24 hours

- Accredited with ISO 9001, 14001, 45001, and SC21 certifications.

- Over five decades of unwavering commitment to the aerospace and space sectors

Why you should choose us…

We prioritise meeting the exacting demands of the aerospace and space industries, offering tailored solutions to address their unique challenges. Our focus on precision and accuracy guarantees that each component we produce adheres to the highest quality standards.

Whether it’s crafting intricate parts with complex geometries or providing material flexibility for diverse applications, our capabilities are vast. In an industry where every component is critical to mission success, we are proud to be a trusted partner committed to excellence. With our expertise in chemical etching and unwavering focus on quality, we are positioned to drive innovation and progress in aerospace and space manufacturing.

For more information, you can follow us on LinkedIn by clicking here.

To find out how we can help you