Expect more from your metal fabrication partner

For over 50 years, Photofab have developed and evolved real ‘value added’ services that have helped our customers overcome the frustrations of managing multiple supply partners. We have combined ‘old school’ human customer service, with modern technology and efficiencies to offer a complete manufacturing partnership.

Whilst Photofab continues to be renowned as world leaders in chemical etching, our offering has expanded to encapsulate the whole process from start to finish. This essential set of solutions has been a ‘game changer’ for our customers, not only alleviating supply headaches, but creating a far more efficient process. Our quality managed service ultimately delivers faster with tighter tolerances that ensures less waste and better profitability for our customers.

Quality Management Service

Etching a better service since 1968

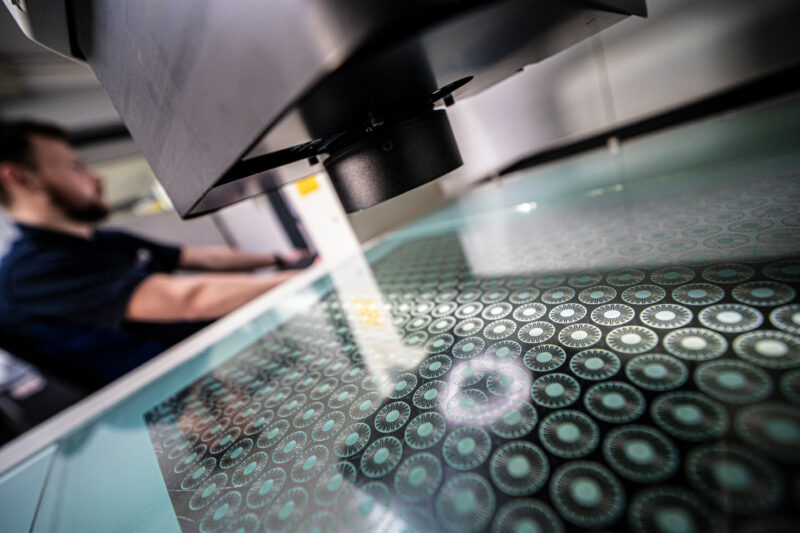

It all starts with your idea, creating the reality is where Photofab delivers the real value of the partnership. From first contact, your dedicated Account Manager will understand your aims, advise, and manage your expectations, before helping you through the entire process. Our automated plotter and team of digital tooling experts create the most accurate and efficient layout for your project.

The right materials are critical to the production process, Photofab have a skilled material handling department to advise and handle materials. All our materials are fully traceable and are quality checked to ensure correct grades and specifications are met.

Material and lightroom preparations are all handled in-house, right through to our chemical etching department. Photofab have five multi-chamber etching machines, capable of faster etching on thicker materials. This is all supported by our production team, who are highly experienced in high-volume orders.

What Photofab Can Produce For You

Formed Components

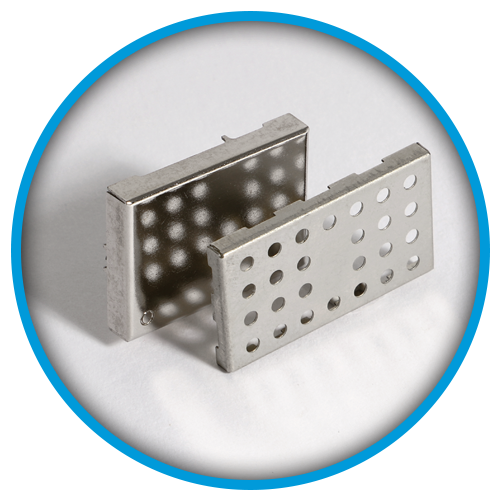

EMI / RFI Shielding Products

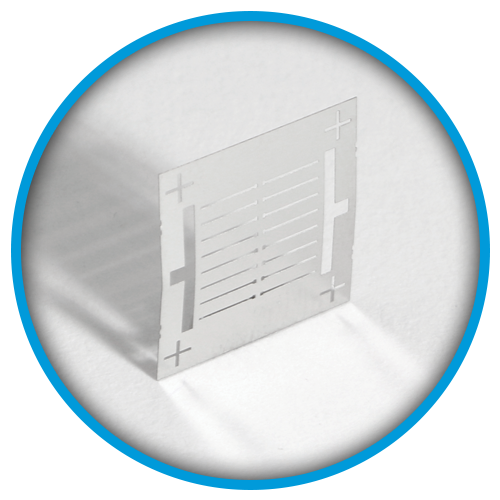

Masks and Stencils

Encoder Discs and Actuators

Formed and Flat Springs

Metal Laminations

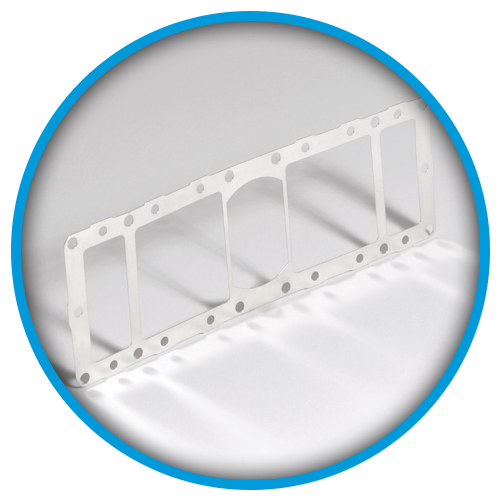

Gaskets and Seals

Electrical Connectors and Electronic contacts

Metals Shims and Spacers

Metal Fuel Cell Plates

Filters, Meshes Screens & Grids

Custom Components: “if you can draw it, we can make it”

Nobody else has as much experience in the chemical etching process. Photofab is on hand to deliver outstanding results every time.

Quality manufacturing

Along with our ERP (Enterprise Resource Planning) system to monitor and control order progression, quality control checks are made at every stage to ensure our high standards are met and strict tolerance control is maintained throughout.

Achieving the SC21 bronze award for maintaining 98% operational excellence across our entire production process for seven years in a row is a testament to our success, reinforced by our ISO 9001 for quality, ISO 14001 for environmental management and ISO 45001 for the worldwide standard in health and safety management. Quality assurance is one of the many reasons customers trust Photofab as their preferred manufacturing partner.

Dedicated engineering

Photofab continuously invest and innovate to improve our service offering and have recently opened a dedicated engineering unit for tooling, forming and finishing. We also have close working relationships with specialist partners for additional manufacturing services, ranging from stamping and laser-cutting to plating, anodising and heat treatments. All additional processes are managed closely and delivered with full transparency and traceability.

What are the advantages of chemical etching?

There are a host of reasons why chemical etching is often the method of choice for production of intricate components. Chemical etching involves low-cost tooling, as tooling is quickly created with CAD, and our automated plotter. Our etching process also ensures incredibly high-accuracy burr-free finishes, ensuring smooth and precise final components ready for use in your application. Etching also has the advantage of leaving the properties of the metal unchanged, making it ideal for industrial applications.

From Prototypes to Mass Production

Photofab offers a complete service. From single prototypes, all the way up to ongoing high-volume production. Our experts have the skills to help create effective prototypes and then secure ongoing supply of the final product. One of the key advantages of chemical etching is that prototyping is incredibly easy, with quick turnaround. Multiple prototypes can be printed from the same sheet of metal, reducing costs and making it easier to refine the perfect product, which can then be put into full production.

Etching to get started with the fabrication experts?

Get in touch with our team of account managers to see what Photofab’s chemical etching process could bring to your business. Photofab enjoys high customer retention because of our commitment to excellence. Every order is assigned a dedicated account manager who will be on hand to deal with any queries you may have and see your order through to completion.

You can keep up to date with Photofab by following us on LinkedIn and Twitter.