When slow and steady won’t win the race – An increased desire for rapid turnaround

The rapid supply of metal components to industries reviving their production schedules as the cold winds of Brexit and Covid-19 begin to settle has become a positive trend.

There is more enthusiasm from industry leaders as their outlook for 2022 highlights a clear shift from survival to growth, and opportunities to bring new products to market. Speed will be of the essence as many industry sectors play catch up. The automotive and aerospace, along with many other industries will know all too well the difficulties that the global shortage of microchips has caused. And we have all seen news footage of cars sat dormant on halted production lines.

The positive industry outlook though is a sign of light at the end of the tunnel and manufacturers are now looking to get back to normal as fast as possible.

Even before Brexit and the pandemic, Photofab was set up to respond quickly. Often in manufacturing, the ‘slow and steady’ wins the race approach just won’t cut it. Speed of response, prototyping, production, and delivery can be the difference between getting to market fast or losing competitive advantage completely.

An introduction to the rapid turnaround service and capabilities

Nikki Reeds introduces Photofab’s unique rapid turnaround service and capabilities in this informative 2 minute video.

Rapid 24-hour turnaround from quoting to delivery

Photofab always aim to quote within 24 hours for standard chemical etching work, or even faster if the customer has the need. The service doesn’t neglect other important processes either, such as full traceability of raw materials, and fully documented and tracked process control.

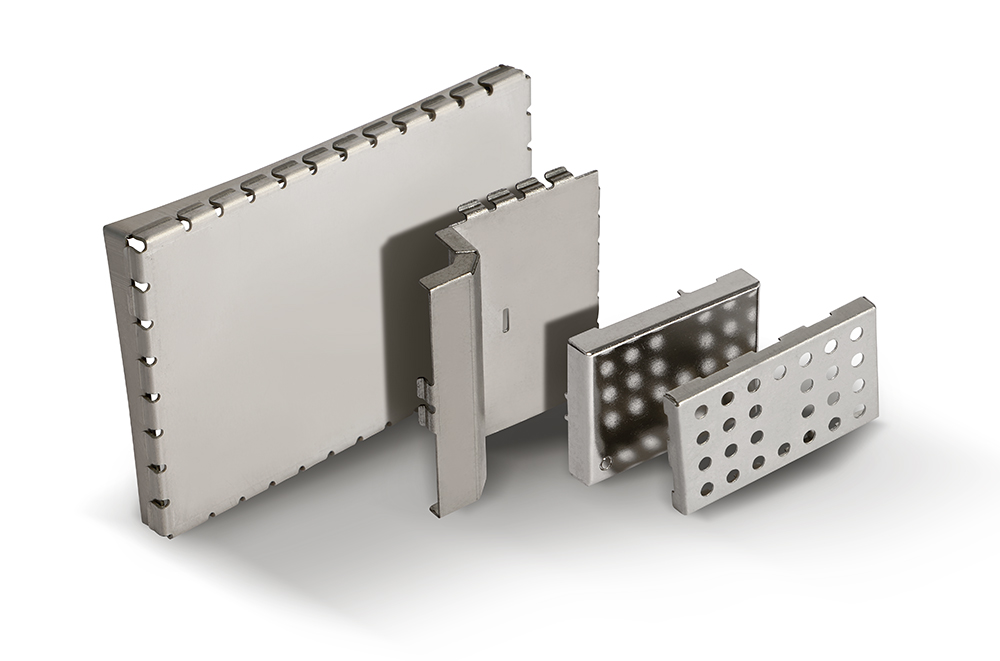

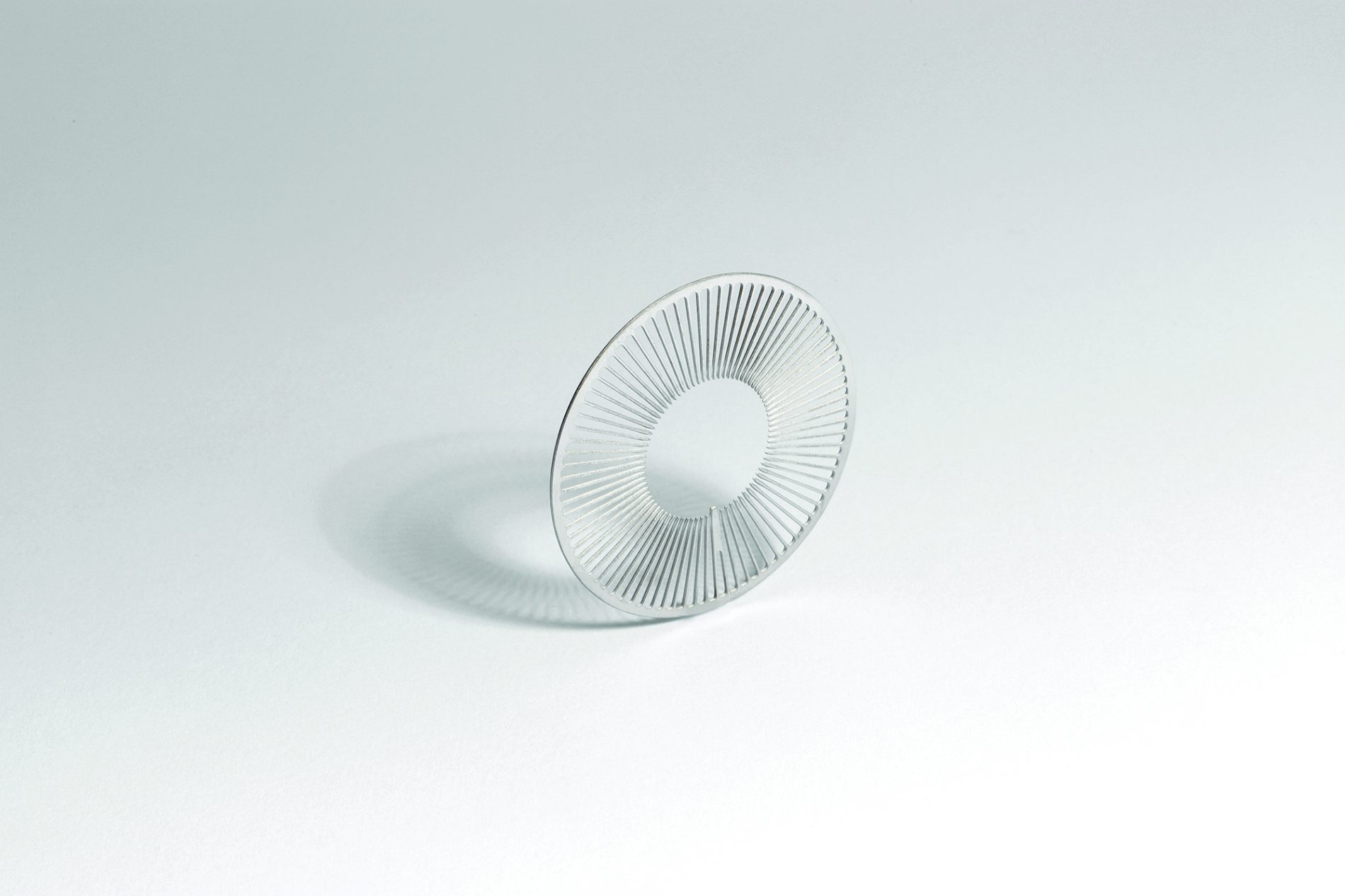

Photofab’s rapid turnaround capability has long been a relied upon service for component production. Whether battery contacts, connectors, gaskets, diaphragms, or any number of complex precision parts, Photofab utilises digital tooling to quickly produce one-offs and prototypes.

These digital tools, comprised of electronic files can be updated easily, and offer the flexibility to transfer designs to any grade of sheet metal between 0.01mm and 1.5mm thick. And not just one design – a single sheet can comprise several designs.

Thanks to the process, efficiencies can be made when design tweaks are required too. Without the barriers and expense of mechanical tooling being developed and adjusted with every component design tweak, Photofab’s customers get the luxury of true production agility – A major differentiator between chemical etching and alternative metal working techniques.

On many occasions, Photofab has turned samples and prototypes around within 24 hours, putting customers in prime position to ramp up volumes and get to market quickly.

Time to market pressure

With efficient tooling and production techniques, alongside a high number of different materials in stock at any one time, Photofab is prepared for any peaks and troughs in demand. An agile response to the production and delivery of components is always satisfied, and it is this dedication to moving quickly that puts customers in an advantageous position.

Gaining a competitive advantage may have always been any manufacturers desire but recent scenarios have only increased that desire as they accelerate R&D initiatives and product innovation. This is most likely due to the need to innovate quickly and also get to market quickly in the medical industry as it reacted to the global demands caused by the pandemic. This notion of speed has influenced almost all industry sectors and with-it significant pressures on the supply chain.

Manufacturers with demands for their products on the rise, or where new products are conceptualised before releasing them to market will have a window of opportunity to help them maximise revenue. Late product launches or increased lead times will negatively impact revenue and cause the product to become obsolete faster as competitors take advantage. This needs to be avoided at all costs and every stage in the manufacturer’s supply chain will need to be singing from the same hymn sheet – And there’s no avoiding the high tempo of this particular song.

Photofab’s years of refinement when it comes to a service built on the need for speed, has positioned the business as the go-to chemical etching partner for manufacturers who want to avoid missing their window of opportunity by receiving the parts they need fast but also to the quality standards they specify.

Quality always

A tacit assumption of many is that speed and quality are opposing forces. Far from it! Necessary processes to ensure component quality are never removed to speed up production and delivery. This would actually have an adverse effect on time to market for the customer as the likelihood of components being rejected or returned would be increased.

Component manufacturers stringent on quality like Photofab will have the relevant accreditations and approvals to back up any quality claims. In Photofab’s case, demonstrating rigorous product quality standards as well as high levels of customer service are proven through its SC21 certificate and ISO 45001, 14001, and 9001 certificates.

Photofab produce detailed method sheets for every job to ensure repeatability of quality standards and full traceability, and also statistics on proof of delivery times for quick turnaround work are available.

Speed is actually more about efficiencies than anything, whether it’s the effective use of digital tooling, multiple component designs on a single sheet of metal, the real time data collected and used to drive effectiveness in the manufacturing process, or the dedicated account managers offering a single point of contact to keep projects on track – It’s a combination of everything that makes for a unique service like Photofab’s rapid turnaround. Try it today and benefit tomorrow.

Keep an eye on the blog series

Keep a close eye on the news section and LinkedIn for content in the coming weeks and months detailing Photofab’s rapid turnaround service and the nuances that make it a reality. Next up, the blog will focus on people and processes.

If you wish to learn more about Photofab’s expertise and how you can benefit from the capabilities and services detailed in this blog, use the contact page to tell Photofab what you need and a member of the team will get back to you in no time.