PROTECTING YOUR ELECTRONICS WITH EMI AND RFI SHIELDING

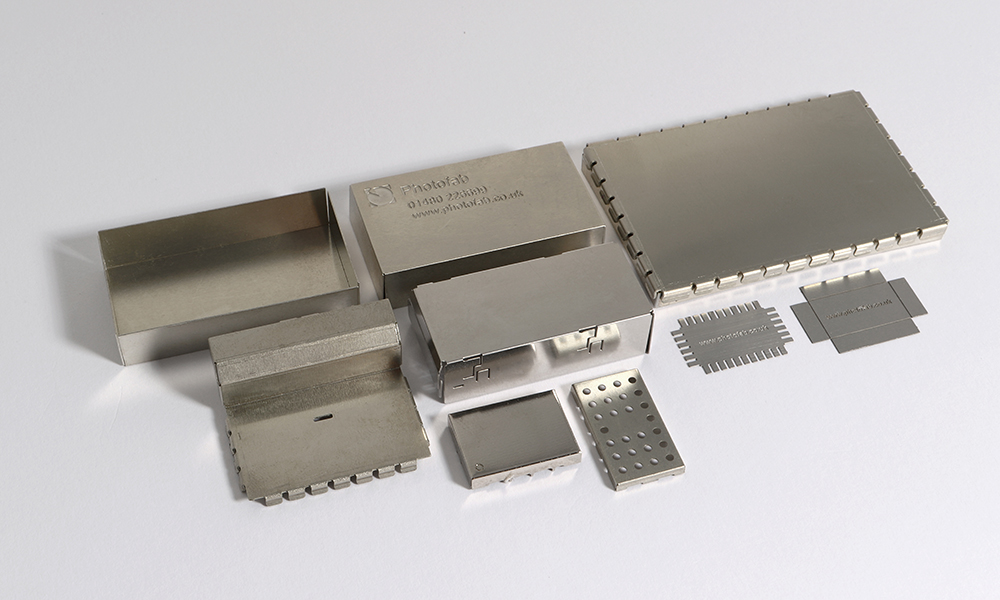

Shielding electronics from Electro-Magnetic Interference (EMI) and Radio Frequency Interference (RFI) is a critical part of circuit board manufacturing to ensure the integrity of electronic and electrical products. With increased demands in regulation and connectivity, design and manufacture of precision screening cans are even more critical. For many years, Photofab have become the trusted partner for many leading electronic OEMs to manufacture and supply these essential components.

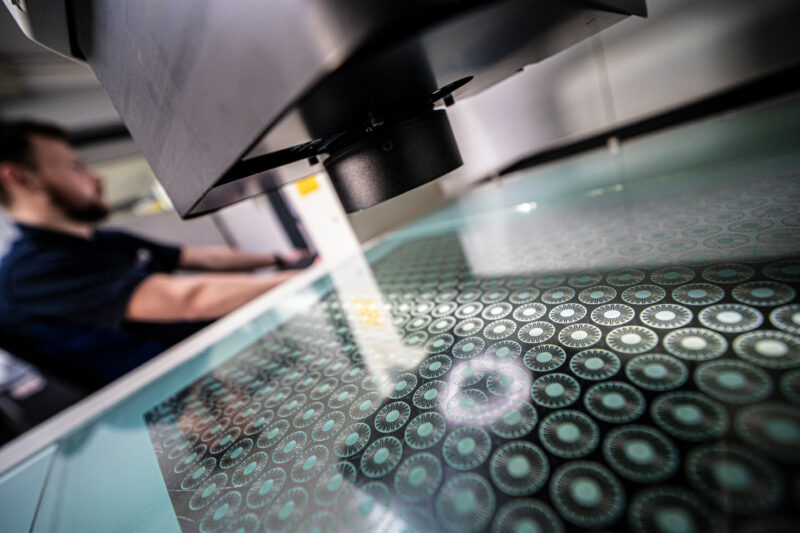

Cost-effective, precision engineering with chemical etching

Choosing chemical etching for the manufacture of EMI and RFI shielding components offer a multitude of advantages, including high tolerances, cost-effectiveness, and no changes to the material properties throughout the etching process unlike other manufacturing methods.

We also offer custom screening cans, fences and enclosures.

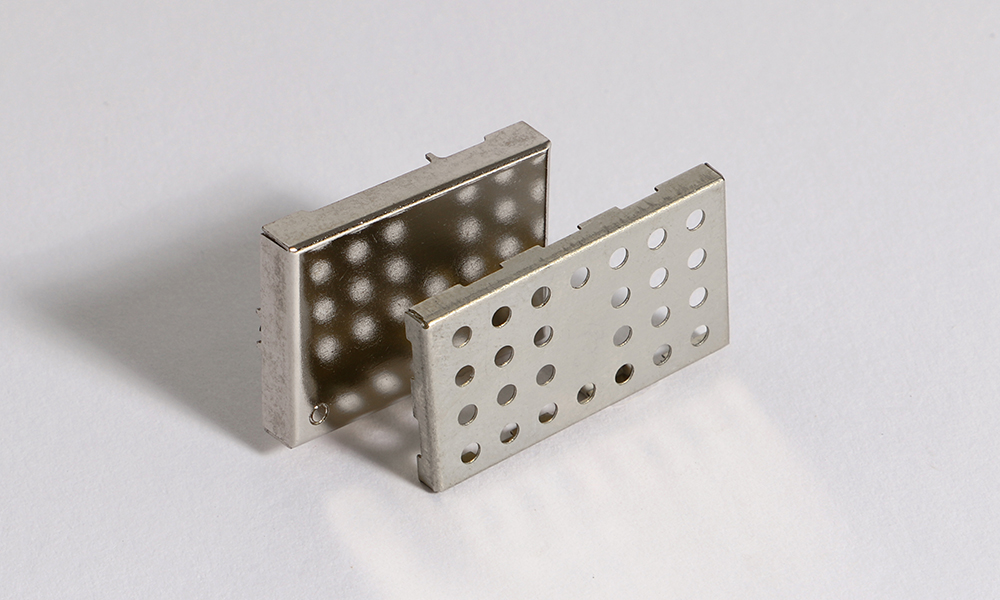

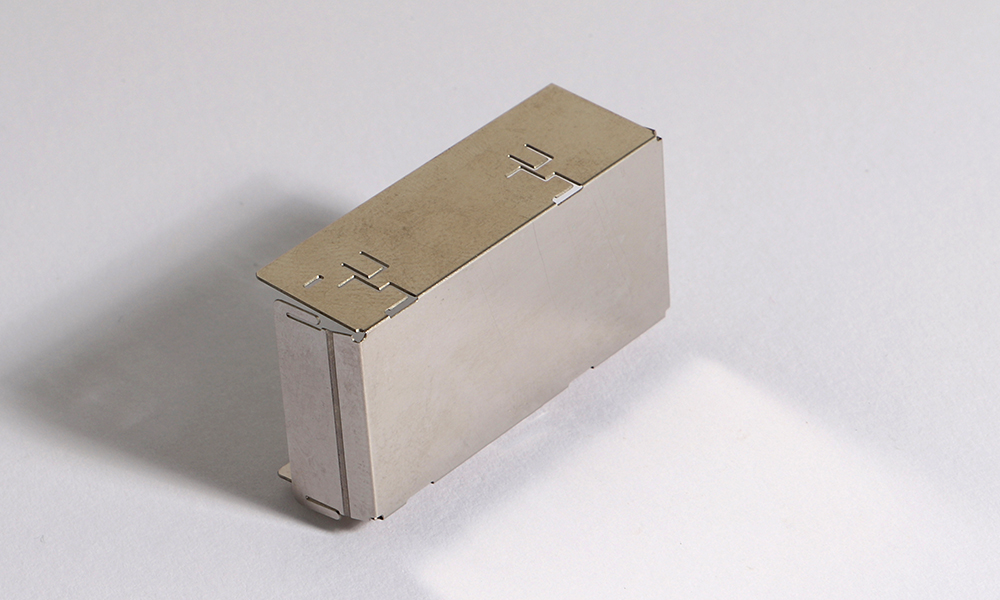

Photofab can also provide enclosures/fences and lids to make a can if the customer prefers. The lids have spring fingers, which means they fit and lock into place to form a can design.

Choice and flexibility

As the tooling process is digital, changes can be quick and at low cost. This can include multiple designs like 5 sided cans or fences with spring lids on a single sheet, saving valuable time, waste, and money. This service is incredibly efficient, ideal for prototyping through to high volume production.

The perfect burr-free finish

Chemical etching is the ideal process for the manufacture of EMI/RFI shielding components that require high tolerances and specifications. With Photofab’s expertise, we can manufacture burr-free using the highest quality materials.

The key advantages of chemical etching of EMI and RFI components

Screening cans can be supplied in a wide choice of lids, sidewalls, and mountings; with Fences, Spring-finger lids, and Simple fold lids.

- Low cost, film-based tooling, unaffected by design complexity and easily modified

- Burr and stress-free finished product, preventing corrosion and ensuring good flat contact with track surface

- Part-etch bend lines, negating the need for ‘hard’ form tools

- Choice of metals – including non-ferrous metals required for hi-frequency applications

- Plating finishes are applied when all profiling is completed, so all ‘machined’ edges of the profile are fully protected and prepared for efficient soldering.

Photofab can offer combinations like: Five-sided enclosures , 4 sided cans with spring fingered lids, 4-sided fence with plan folded lid, 5 sided can formed and spot welded, 5 sided can formed for surface, 5 sided can supplied flat for self-forming.

By choosing Photofab, we can offer fast turnaround and rapid prototyping to iterate on designs until the perfect solution is found. Chemical etching allows for production at all volumes, making prototyping simple – with many prototypes being able to be produced on the same sheet of metal!

On form to engineer precision

Photofab have a dedicated engineering division for tooling and sheet metal forming, supporting our world-leading chemical etching service. Proven to be an essential part of the production journey, Photofab have heavily invested in this secondary unit, offering a full solution to the EMI and RFI shielding service.

Dedicated support throughout your production journey

From initial contact, you will have your own dedicated account manager, who will help advise you and suggest the most efficient processes for your RFI shielding project and can quote within 24 hours. Once the project and timescales have been agreed, it will be added to our ERP (Enterprise Resource Planning) system to monitor and control order progression. Quality control checks are made at every stage to ensure our high standards are met and strict tolerance control is maintained throughout.

We can ensure full traceability and offer exceptional lead-times from as little as 24 hours, this service is backed up with ISO 9001, 14001, 18001 and SC21 accredited processes.

Get shielding from the chemical etching experts

Our commitment to excellence and customer service mean we enjoy high customer retention. Get in touch with us and find out why first-hand! You’ll be assigned a dedicated account manager who will always be on hand to deal with any queries.

You can stay up to date with the latest developments from Photofab on LinkedIn.