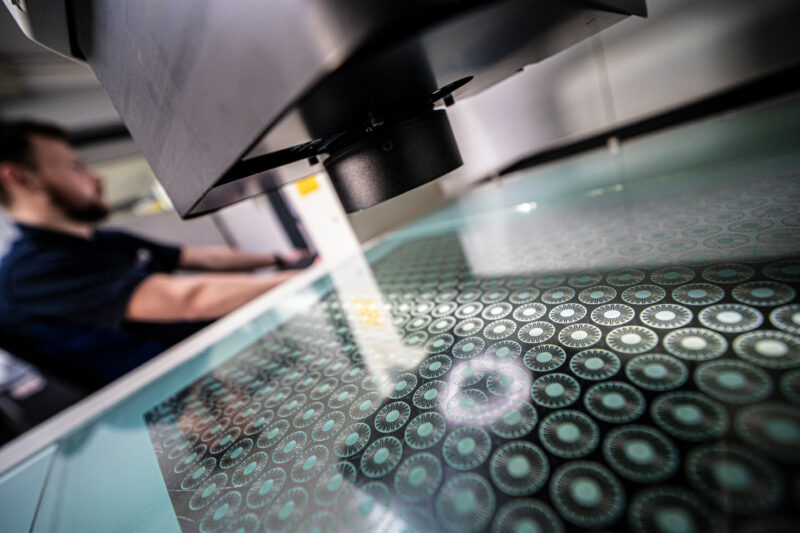

TURNING UP THE VOLUME ON CHEMICAL ETCHING

For cost-effective, high-volume manufacturing of precision flat or formed components, Photofab has become the first choice for many of the UK’s leading OEMs and suppliers. We deliver the complete solution for our customers, managed throughout by a dedicated account team, providing a fully traceable and reliable service.

Maintaining our SC21, ISO 9001, 14001 & 45001 quality processes, enables us to achieve the highest standards of production with over a 98% On Time Delivery record. When speed is of the essence, our 24-hour quoting, digital tooling, multi-chamber etching, and automated stripping line accelerates production.

Smarter prototyping

Photofab have partnered with so many companies to help get their prototypes off the ground. Chemical etching is an ideal process for prototyping, thanks to a number of factors. For one, many different prototypes can be printed on a single sheet of metal, reducing waste and cost. On top of this, iterating is made easy with our digital tooling, which lets us easily make any changes you require quickly and cost-effectively. In addition, our experts can advise you on the most appropriate materials to ensure your design can be made into reality and perform as expected.

Why you should choose Photofab

KNOWLEDGE

Over 50 years of expertise and experience with a highly trained team of specialists delivering high volume orders.

CAPACITY & SPEED

For cost-effective full volume orders of hundreds of thousands. We also offer fast turn-around, as little as 24 hours.

SERVICE

Our dedicated account managers are experts and there to help, advise and manage.

RELIABILITY

Trusted by thousands of OEMs to deliver quickly and accurately.

QUALITY

SC21, ISO 9001, 14001 & 45001 quality processes.

TRACEABILITY

Fully traceable materials and processes.

Maximum cost-effectiveness

When it comes to full production, Photofab runs highly efficient operations which can produce precision parts fast. One of the advantages of chemical etching is that every piece comes out identical, with no tool degrading. This gives a level of consistency that can’t be found in other production methods. For flat components, we can even produce parts in as little as 24 hours. If this service is of interest to you, please don’t hesitate to reach out to us, where a dedicated Account Manager will be on hand to manage every aspect of your order.

Photofab are the experts at maximising the number of components that can be produced per sheet, reducing the cost per part and increasing Return On Investment for you.

Volume up production

For projects that require ongoing high volumes, we offer automation and 24-hour production, all maintained to exacting standards. Combine this with our extensive and trusted manufacturing partnerships, we can offer a multitude of quality manufacturing services to meet your requirements.

Try Photofab for your next project!

Find out how chemical etching can transform your supply chain. We enjoy some of the highest customer retention in the industry, thanks to our world-class, customer-focused approach. Every order is treated with same care and attention by our team of dedicated professionals. So, try us today. Keep up to date with latest innovations on LinkedIn.