Your essential partner for full-service prototyping

Prototyping is a critical part to any manufacturing process, a time sensitive and necessary step to ensure the success of high-volume production. Understanding this has enabled Photofab to develop full-service prototyping, which offers a cost-effective and flexible package aiming to exceed customer’s expectations on quality and delivery.

The critical ingredients;

Quality, Cost and Speed

With over 50 years of experience in chemical etching, our success in prototyping is understanding the importance of these key ingredients. By listening and understanding the needs of our customers we can draw on our extensive knowledge and expertise to better advise and plan the best manufacturing processes. This refined process produces quality precision products that are cost-effective and delivered in the shortest time possible.

A flexible, full-service offer

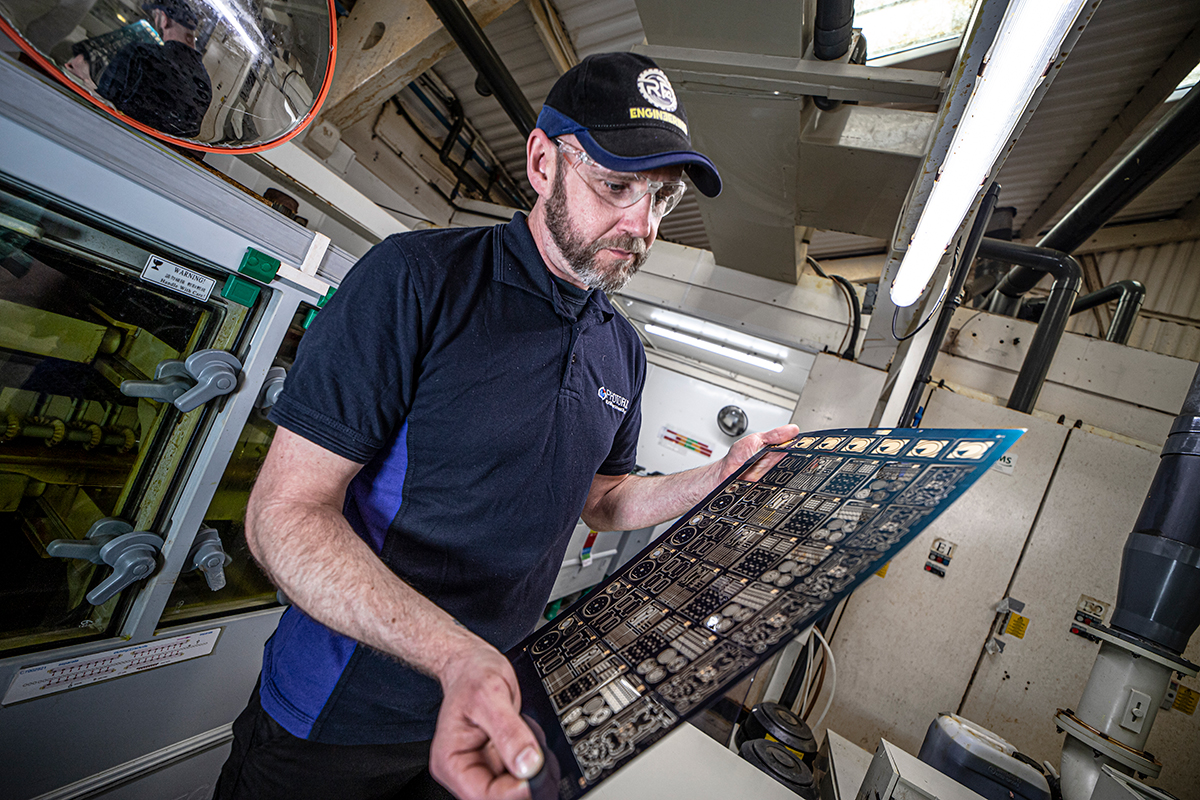

Continuous investment into the business and the team has delivered the latest advancements in technology and processes. One of Photofab’s game changers is digital tooling, this dramatically speeds up the tooling process for a fraction of hard tooling cost. The flexibility in this service is significant, with quick and easy changes to specifications, faster lead-times, and multi-component designs all on one sheet.

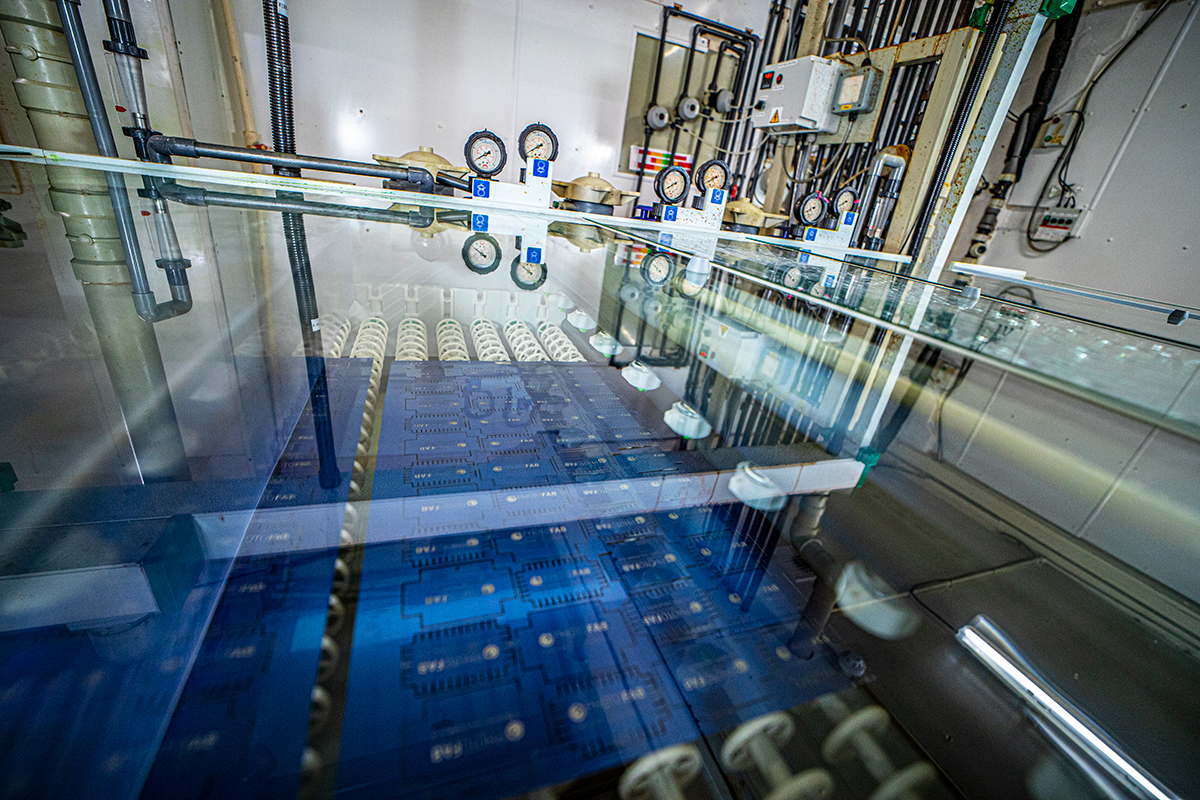

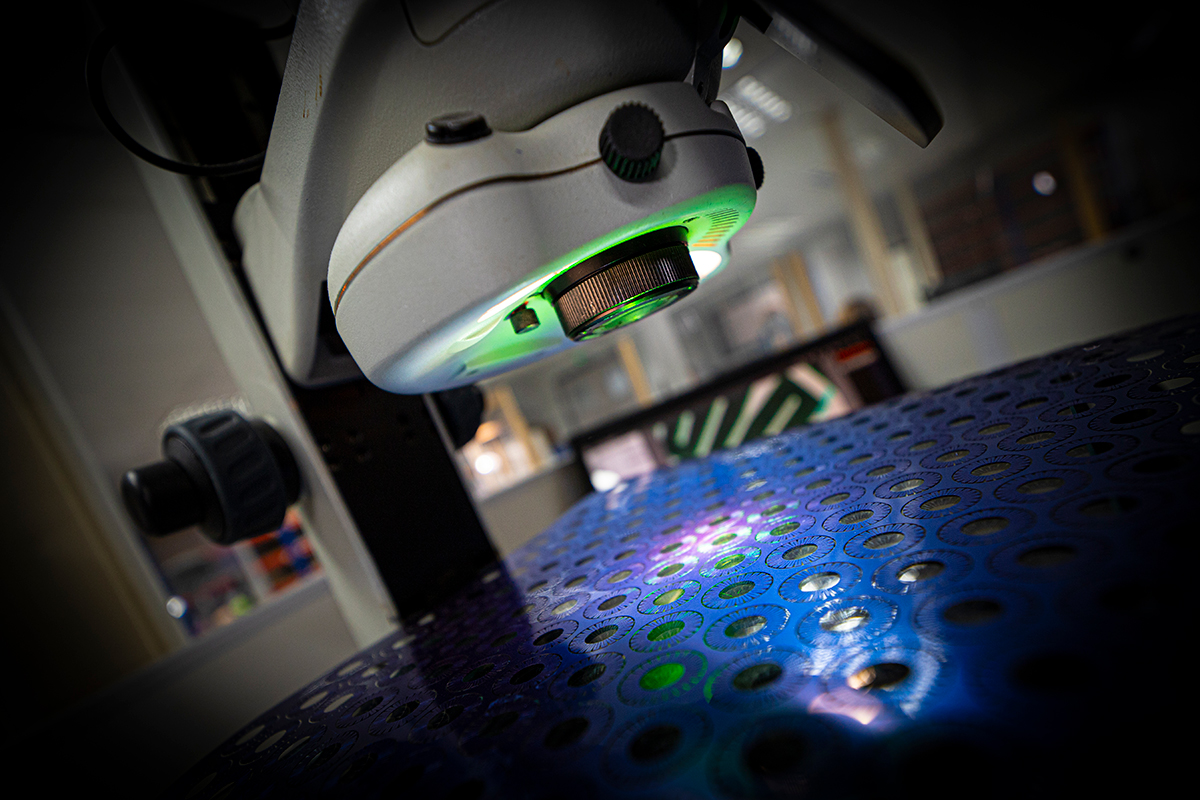

Our world leading chemical etching takes centre stage as the next step in prototype manufacture. This service offers speed and precision, utilising the same tool for a single part or high-volumes and produces precise burr-free components.

One of the added advantages of chemical etching is it leaves the internal structure of the metal unchanged.

The entire process from quote to delivery has a dedicated point of contact, reinforcing the production process, with full traceability throughout.

Value added partnerships

Photofab also have long working relationships with specialist partners for additional finishing services. These services can range from laser-cutting, plating, anodising and heat treatments which can add decorative finishes, prevent corrosion, and further improve durability.

All additional processes are managed closely and delivered with full transparency and traceability.

Talk to our team

Call one of our dedicated team of account manager’s today or contact us now to see how Photofab can add an extra dimension to your prototyping or precision manufacturing project.

Keep a close eye on the news section and LinkedIn for content in the coming weeks and months detailing Photofab’s automated processes, and how this and our other services can benefit your project. Follow us on LinkedIn and Twitter for our latest news.