Taking to the skies with Photofab | Aerospace & Defence sector focus

The marvel of aerospace is truly something to behold, particularly the intricacies that are involved in keeping aircraft in the air. From the pioneers of Orville and Wilbur Wright and their innovative Wright Flyer, to the Ingenuity helicopter that recently flew unmanned on Mars, the industry has come on leaps and bounds in over 100 years. It is fascinating to think of what could be in the future of air travel.

A great proportion of the world’s defence sectors rely on the strength of their nation’s aerospace capabilities. There is a heavy crossover between these two sectors, and the need to innovate and move with the times has never been stronger. This is where Photofab comes in, providing elaborate and detailed parts for all types of aircraft both new and old.

Nikki Reeds introduces the Photofab capabilities helping industry take to the skies

Aviation, such an innovation

Photofab’s established background in the aerospace and defence sectors include working on military helicopters and aeroplanes, as well as commercial airlines and corporate requirements. The variety of jobs that Photofab manufactures for gives the organisation a wide range of experience, meaning it is ready for any type of customer.

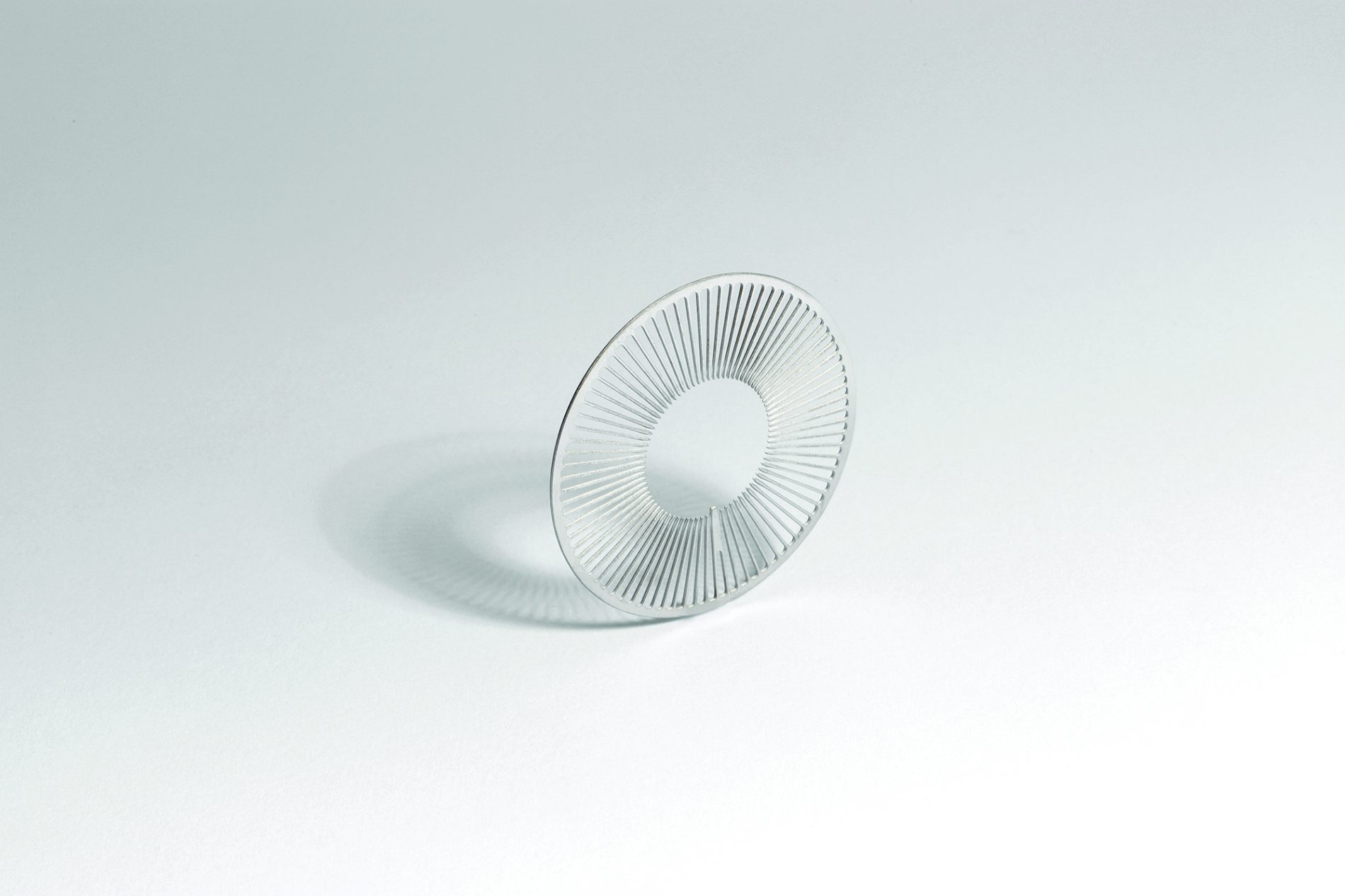

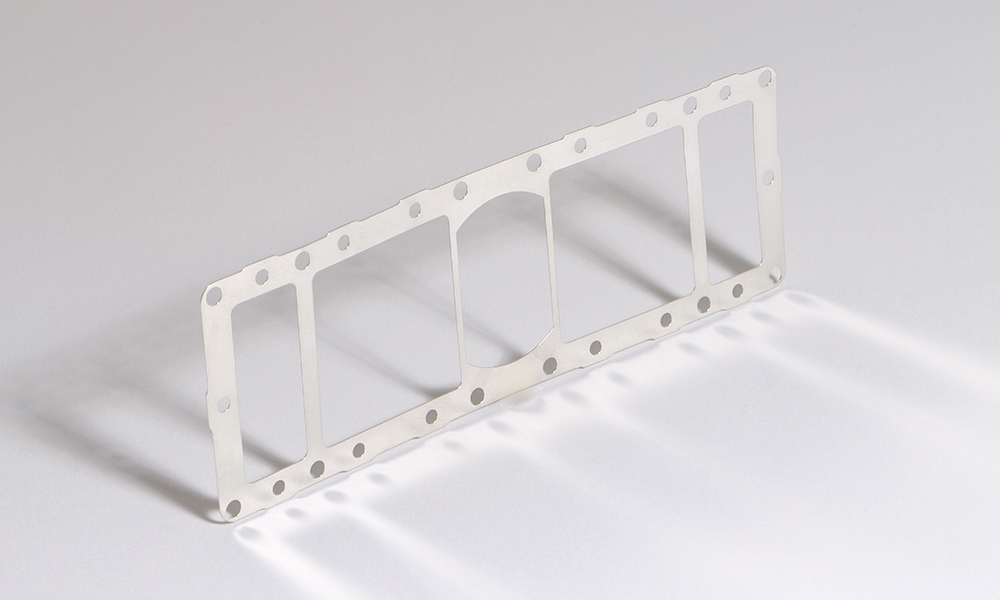

There are several examples of components manufactured by Photofab for these industries, including shims for missiles, infrared cameras, tracking systems and detectors. For the military in particular, seal plates, bus bars, rings, earth tags, drive plates and spring washers are produced.

Providing small parts for such huge aircraft boggles the mind. The number of parts that go into these machines is unbelievable, ranging from mechanisms in the wheels, all the way through to the complex radar systems and electronics onboard the aircraft. Photofab’s capabilities include making shims, end screens, clips and various springs that are used on modern day aircraft.

How does Photofab keep everything flying?

The rate at which such capabilities change is so unprecedented, especially in the defence sector, where being on top of technological advancements is of huge importance. Sectors constantly face changing requirements through research and development, or legislation in terms of innovation, quality, speed etc. and therefore Photofab continues to stay up to date on the latest technological developments.

There are modern jets around the world that play a huge part in air forces, keeping citizens safe around the world. Some of these jets feature innovative technological advancements, and even require computers to keep them in the sky! And guess what? Photofab works with such aircraft – we may be a long way from seeing planes more advanced than these!

With specialist aircraft even travelling to space nowadays, the components Photofab manufactures must be able to operate in various conditions and temperatures. They say in space, no one can hear you scream, which is true… but it is also freezing cold! If aircraft are to continue functioning outside of the Earth’s atmosphere, they require precise and intricate parts made from suitable materials that can handle such a harsh environment, all of which Photofab can supply.

Because these sectors are so diverse and fast-paced, components are likely to change late in the process. Photofab’s prototyping service is vital in such a scenario, allowing designs to be amended until the client is happy. Since time is of the essence, prototyping can save the client valuable time, so that products are fit for purpose as soon as possible. As well as prototyping, Photofab uses the chemical milling manufacturing method to create the precise requirements needed. Photofab offers components that can be made from various materials and finished down to incredibly accurate details.

Along with fast and reliable delivery schedules, these industries require full traceability of the raw materials, which Photofab is always able to offer. It goes without saying that high quality is paramount too, especially in an industry that is responsible for the safety and welfare of many, so materials must be maintained to a high standard to ensure that they do not fail.

With an SC21 Bronze Award under its belt, Photofab has reached fantastic heights of achievement in the 21st Century Supply Chains Programme, an improvement programme designed to accelerate the competitiveness of the aerospace and defence industries by raising the performance of its supply chains. Photofab is regularly renewing its commitment to this quality accreditation, ensuring that standards do not drop.

Where will these industries land?

In such a short space of time, the aerospace and defence sectors have pushed the limits of the imagination. Right now, we can’t comprehend what could be achieved in the next 10, 20, 50 or 100 years. But what do we know now that we can prepare for ahead of time?

For instance, it has been reported that Airbus has revealed three concepts for the world’s first zero-emission hydrogen commercial aircraft, which could be in use by 2035. By exploring various ideas in order to achieve more environmentally friendly options for flight, this alerts manufacturers such as Photofab that the preferences for components may soon change, who then need to act accordingly.

Relying on hydrogen as a power source has become a popular target across many industries, as the decarbonisation of these sectors are crucial to preserving the future of the planet. Photofab is fully aware of these changes, and has recently covered this in a blog post about its contributions to the renewable energy sector, which you can read here.

The aerospace and defence industries are also benefiting from artificial intelligence (AI), which gives users the ability to analyse materials and discover new patterns and relations in the data. The capabilities of AI are huge, as it can handle far more complex problems than humans and operate at a much faster rate. Nevertheless, when you get down to the bare bones of it, AI functions as a result of small parts that Photofab is able to manufacture.

A previous Photofab blog touched on the development of the automotive industry, and many of the goals and ideas mirror up with the aerospace and defence sectors. Travelling from A to B has become a cause for concern because of the potential environmental implications. With constant research and development being undertaken, Photofab is well equipped to meet the needs of customers who are looking for the most modern, up-to-date solutions.

If you wish to learn more about Photofab’s expertise and how you can benefit from these capabilities on your next project, use the contact page to tell Photofab what you need and a member of the team will get back to you as soon as possible. For more stories like this, follow Photofab on LinkedIn and Twitter.