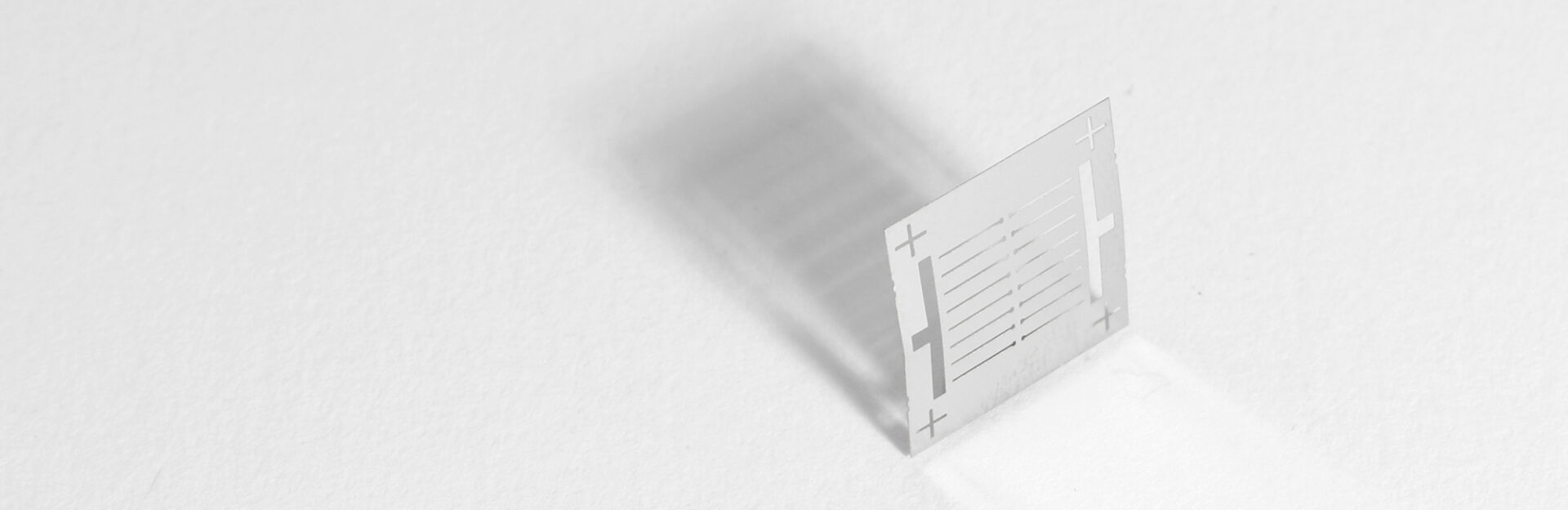

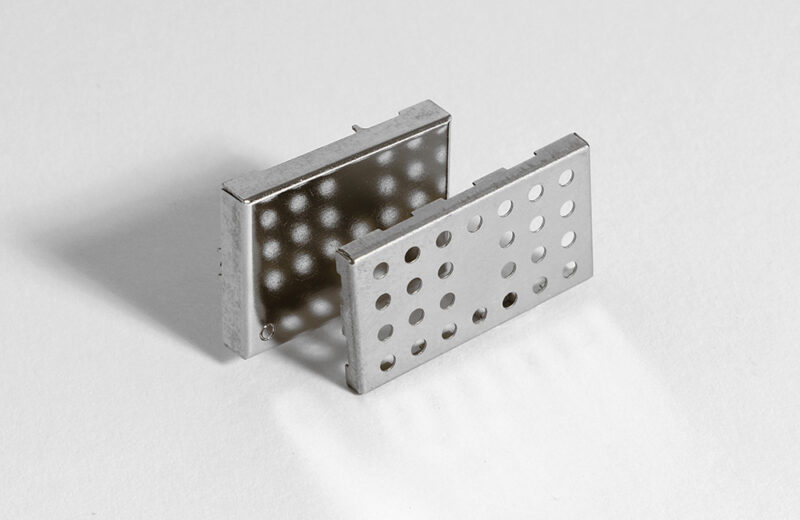

Photofab has a wide experience in the manufacture of metal masks and stencils. Photofab has been producing masks and stencils for industrial use for many years, backed by over 50 years of metalworking experience. We understand that evaporation/deposition masks are often the “workhorses” of the stencil world, and that component quality is integral to ensure a quality outcome. Photofab offers a convenient, cost-effective service with short lead times.

For over 50 years, Photofab have worked closely with leading electrical and electronic manufacturers to adapt and perfect our processes, ensuring the highest standards in quality, precision, and consistency for the manufacture of metal masks and stencils through our industry-leading etching process.

For more information on how we can reduce your costs & improve lead time contact our dedicated account managers on 01480 226699 or email enquiries@photofab.co.uk.

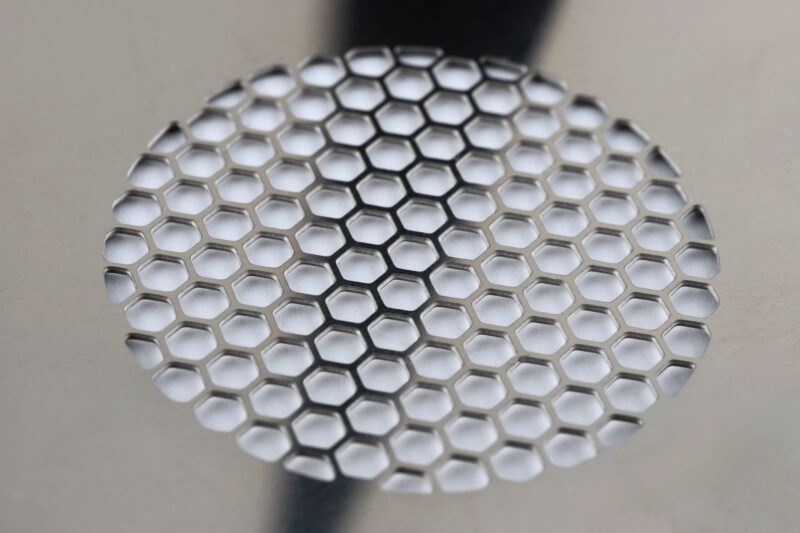

Why Photo Etching is ideal for Masks and Stencils

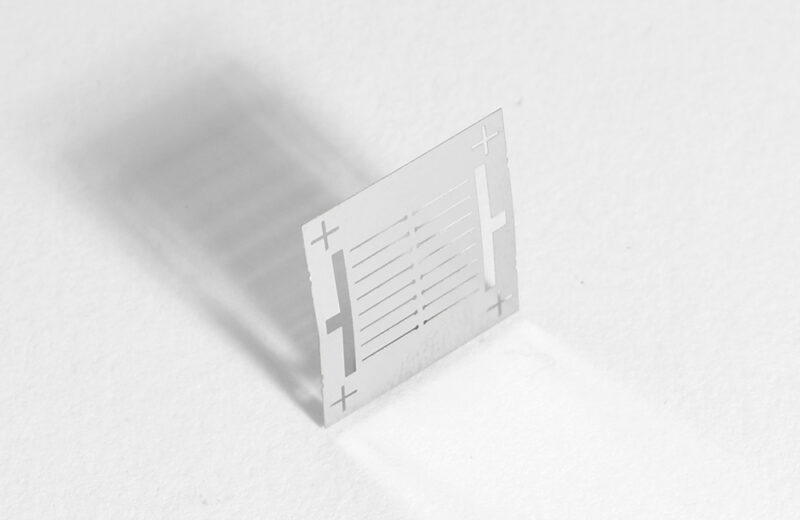

Photofab believes that Chemical Etching is the ideal process for the production of metal masks and stencils. This is because the cost is determined purely by the size of metal foil. The complexity of the design does not affect cost; therefore, we can offer highly detailed designs at the same price. This is because all the detail is etched simultaneously, compared to other solutions like laser cutting which requires each detail to be etched consecutively, increasing the cost.

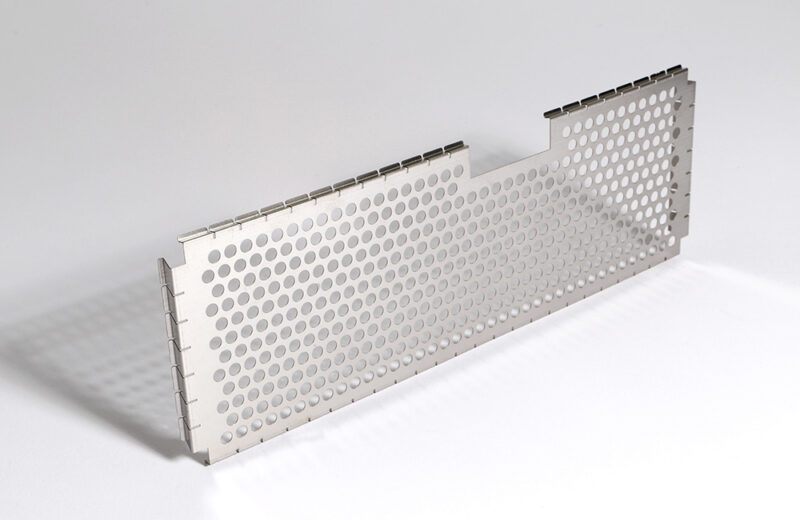

Apertures can be produced with trapezoidal definition. In other words, the squeegee side opening on the component is slightly smaller than the release side size. This leads to improved paste release as the wall shape acts in the same way as an upturned bucket, promoting flow.

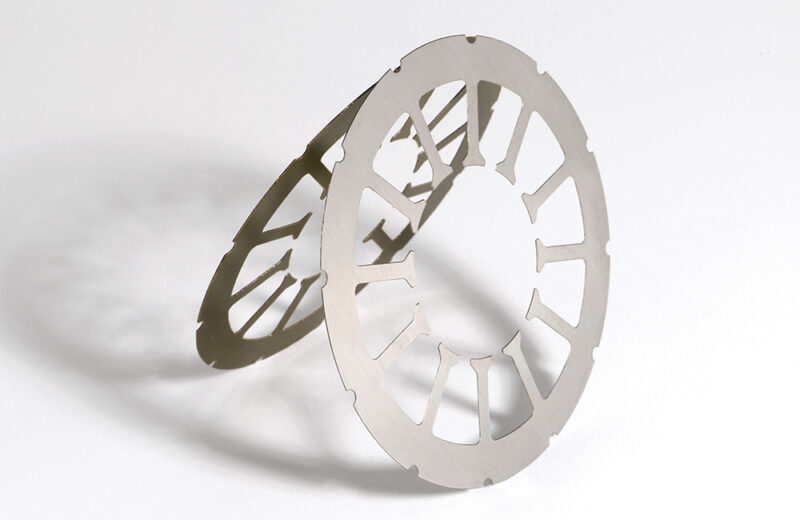

FROM PROTOTYPING to full production – engineered by us

Photofab offers a complete solution, from design and prototype to full production. Before Photofab can be involved in the development of new products, we undertake a stringent design process by which specifications for component prototypes are carefully conceived. This ensures from the outset that your products are fit for purpose once they are in production. Photofab will work with your designs to create viable products and have the capabilities to scale up to full volume production, no matter the process.

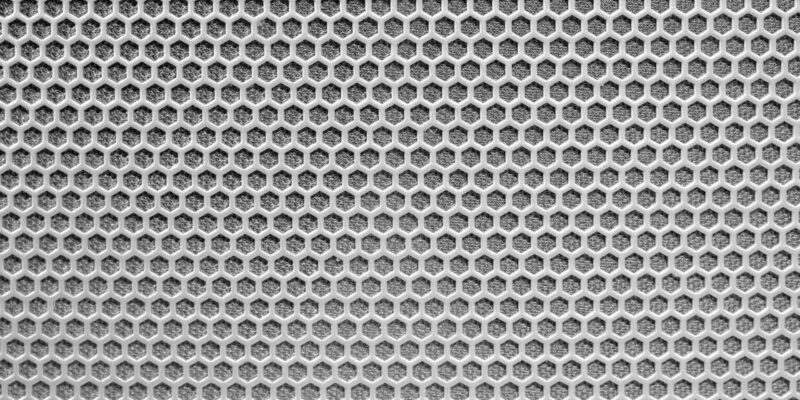

Plated Finish for Maximum Lifespan

Photo etching allows us to plate the masks in either Gold or Rhodium. This has the advantage of improving the lifespan of the mask. In an un-plated mask, the mask becomes coated with the material that is deposited through it. This means the masks must be cleaned – it is this cleaning process that slowly degrades the masks and eventually renders them useless.

On the contrary, with a Gold or Rhodium plated finish, masks are highly resistant to wear through this method as they can withstand the acids used in the cleaning process. In fact, on average Gold and Rhodium plated masks will last 10x longer than un-plated masks. This can only be achieved through a plated finish through photo etching, placing Photofab in the prime position to deliver metal masks for industrial use.

Photo Etching Vs Laser Cutting for Masks

Photo Etched Masks

- No limit to holes/apertures

- Can add a plated finish for longer lifespan

- Burr-Free and Stress-free method of manufacture

- Apertures on both sides

Laser Cut Masks

- More holes/apertures increase cost

- Can’t add plating without separate process

- Material that contacts laser may see its properties changed

- Apertures on one side only per process

DEDICATED engineering

Photofab understands the importance of skilled engineering when designing components and putting them into production. Therefore, we have heavily invested in a dedicated secondary engineering unit, the aim of this is to offer an even greater service and flexibility to our customers.

Originally set up to provide an in-house solution to support the etching division, it has proven so popular with our customers that Photofab are now offering toolroom, forming and finishing as stand-alone services. This means our customers now have access to a new level of flexibility – enjoying the convenience of full-service manufacture or pick and choose services to suit them. It truly is a complete service from Photofab.

Photofab continues to offer cutting-edge services and outstanding lead times, and we can do so because of continuous investment in our people and our processes, leading to class-leading output and lead times – including our rapid 24 hour turnaround service.

The benefits of

working with us

We are world leaders in the development of photochemical technology to produce intricately shaped components. We have produced over 80,000 different components over the years and are highly regarded for our chemical etching process. Our engineers offer many services that you can find here, and will offer advice to improve the product and reduce the costs.

24-hour quotation service

Dedicated account managers

Rapid manufacturing service

Cost saving stock of uni-tooling

Etched fold lines for tool-free forming

Full manufacturing service and supply chain management

Access to manufacturing and technical advice and expertise

Quality accredited to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze

The Photofab difference

One of the key reasons Photofab enjoy its customer retention and longevity is the team of dedicated account managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire Photofab service.

Customers rely on their dedicated contacts’ understanding and in-depth knowledge of their specific requirements and know the highest standards will always be met using the most efficient and cost-effective methods.

This consistent customer service is the foundation of our customer loyalty and is maintained throughout every department and every stage of production. Put us to the test for your next project and call one of our account managers on 01480 226699 or use our customer enquiry form, we would love to hear from you.

start your production journey today

If you are looking to find a complete service include dedicated engineering to design and implement your solution, get in touch with us. You’ll be allocated your own dedicated account manager who is always on hand to advise and take care of everything for you. Call Photofab on 01480 226699 or contact us now to see how Photofab can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn and Twitter.

TAKE A LOOK AT OTHER

PRODUCTS FROM PHOTOFAB

To find out how we can help you

Get in touch today