PHOTO ETCHING

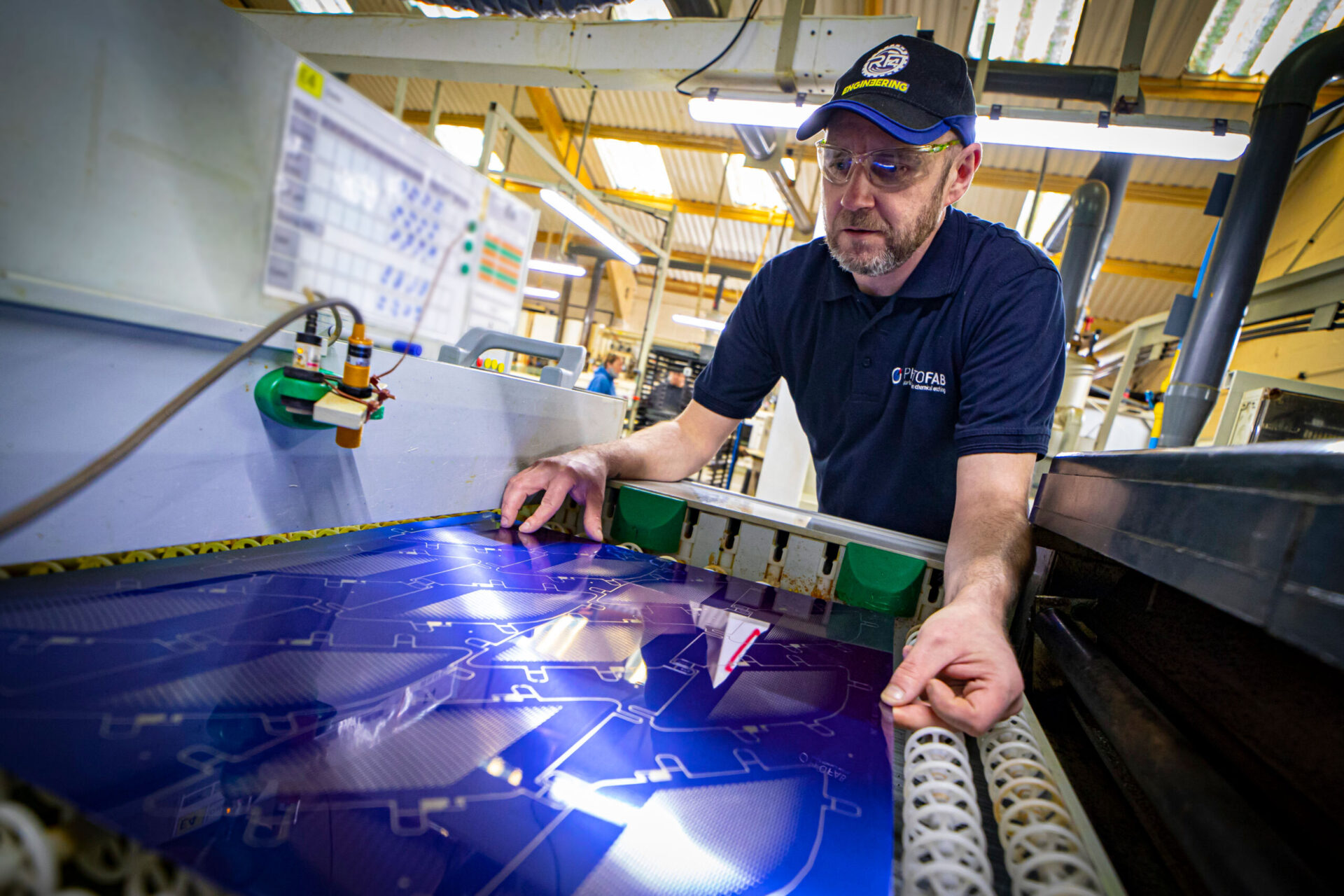

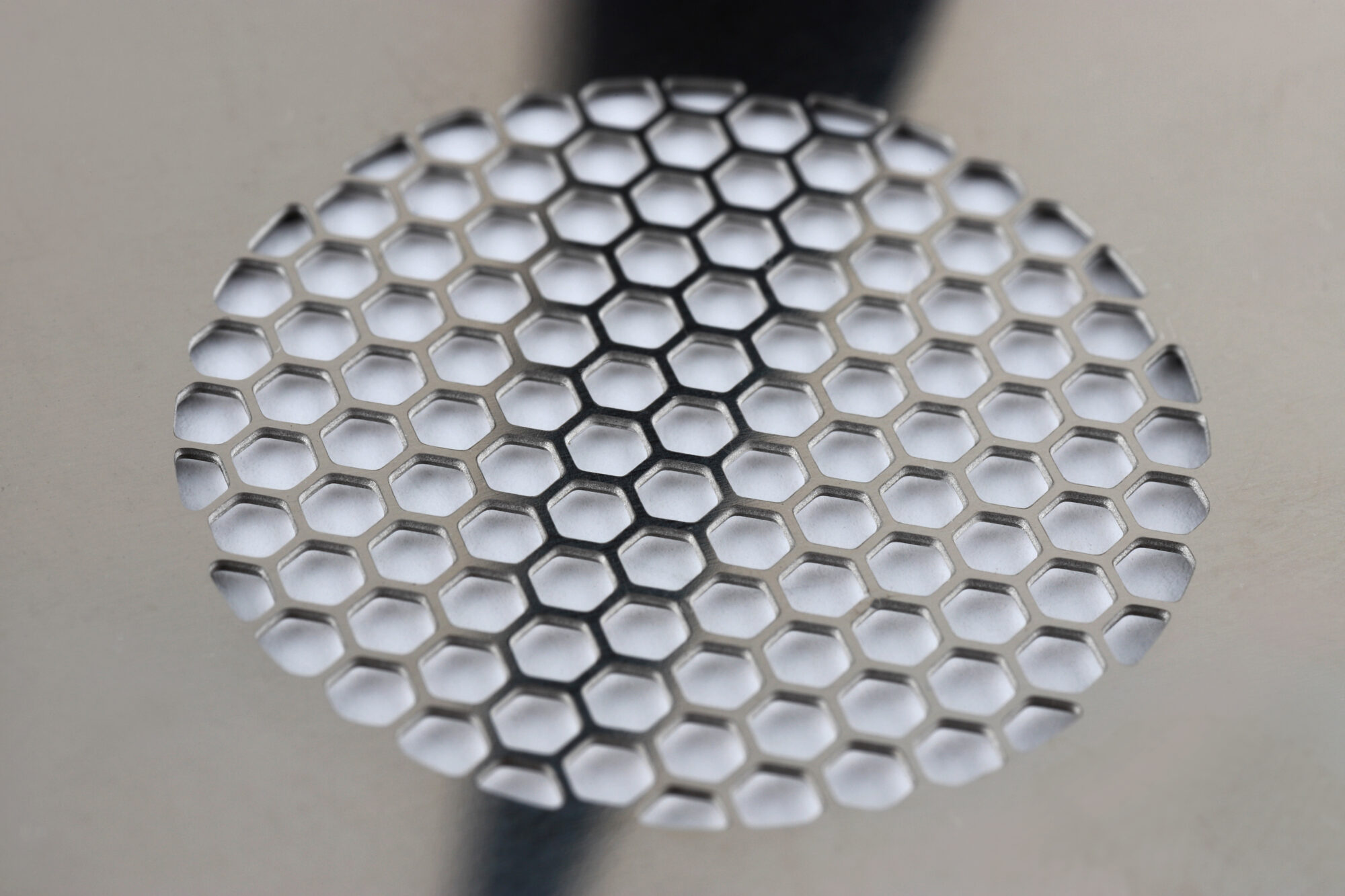

There is a phrase often associated with us and photo etching, “If you can draw it, we can make it”. With nearly 55 years experience and a large pool of technical knowledge, we are specialists in photo etching of thin metal parts.

This means we can offer a metal photo etching service that delivers high accuracy and low tooling costs, all with fast turnaround and delivery.

For more information on how we can reduce your costs & improve lead time contact our dedicated account managers on 01480 226699 or email enquiries@photofab.co.uk.

WHAT IS Photo Etching?

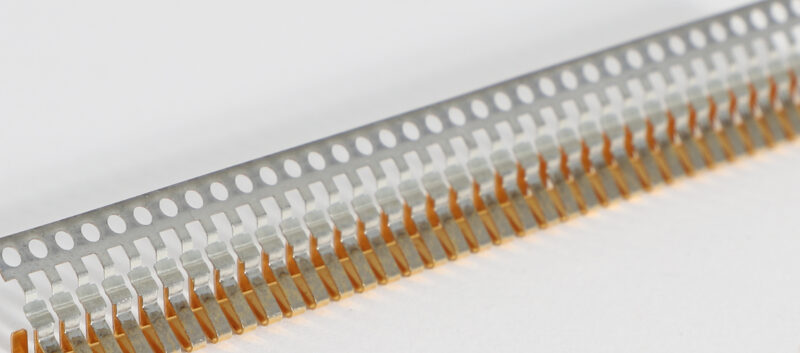

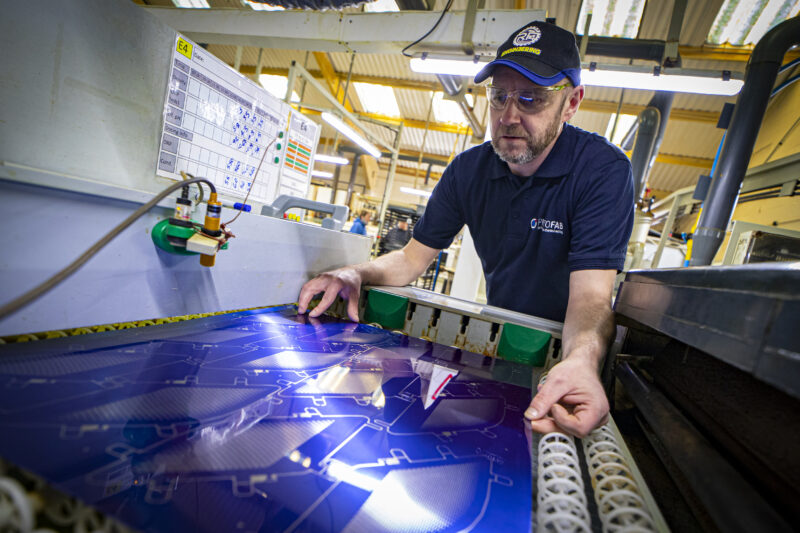

The Photo Etching service is a process used in microfabrication to selectively remove parts of a thin film or the bulk of a substrate.

- UV light is shone onto a component

- A geometric pattern is transferred from a photo mask to a light-sensitive chemical photo resist on the substrate

- Chemical treatments then engrave the exposure pattern into the material underneath the photo resist

Often a term used interchangeably with chemical milling or chemical etching, photo etching has its origins in Optical lithography. The photo chemical etching process is used in microfabrication to selectively remove parts of a thin film or the bulk of a substrate. It uses UV light to transfer a geometric pattern from a photo mask to a light-sensitive chemical photo resist, or simply “resist,” on the substrate.

A series of chemical treatments then engraves the exposure pattern into the material underneath the photo resist. For this process to be successful one requires extremely clean operating conditions, otherwise the bond between the metal sheet and the photo resist will be very weak. Full details of the photo etching process can be viewed on our Process Tour.

There are many advantages to this process:

- high accuracy

- burr free components

- low cost tooling

- fast turnarounds

See the many services that we can offer with photo etching, and also the wide range of products we can produce.

If you think this process can benefit you, please contact us or telephone 01480 226699.

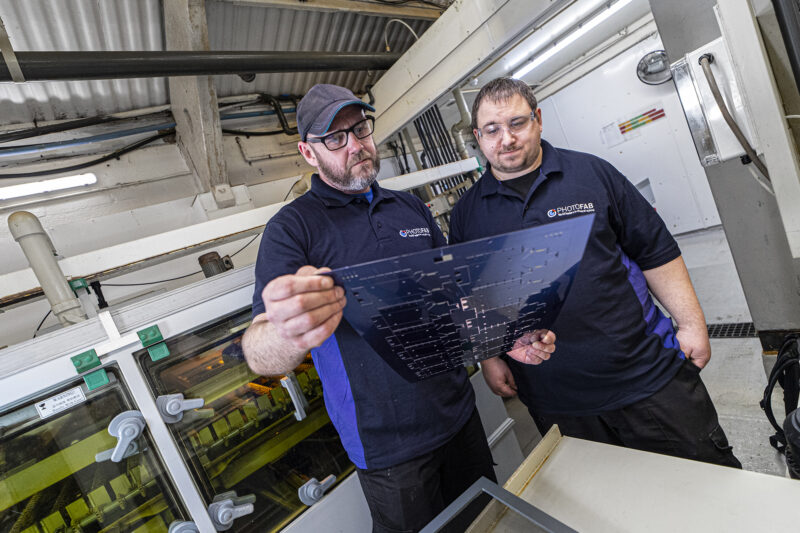

DEDICATED engineering

We understand the importance of skilled engineering when designing components and putting them into production. Therefore, we have heavily invested in a dedicated secondary engineering unit, the aim of this is to offer an even greater service and flexibility to our customers.

Originally set up to provide an in-house solution to support the photo etching division, it has proven so popular with our customers that we are now offering toolroom, forming and finishing as stand-alone services. This means our customers now have access to a new level of flexibility – enjoying the convenience of full-service manufacture or pick and choose services to suit them. It truly is a complete service.

We continue to offer cutting-edge services and outstanding lead times, and we can do so because of continuous investment in our people and our processes, leading to class-leading output and lead times – including our rapid 24 hour turnaround service.

The benefits of

working with us

We are world leaders in the development of photo etching technology to produce intricately shaped components. We have produced over 70,000 different components over the years and are highly regarded for our chemical etching process. Our engineers offer many services that you can find here, and will offer advice to improve the product and reduce the costs.

The key difference

One of the key reasons we enjoy our customer retention and longevity is the team of dedicated account managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire Photofab service.

Customers rely on their dedicated contacts’ understanding and in-depth knowledge of their specific requirements and know the highest standards will always be met using the most efficient and cost-effective methods.

This consistent service is the foundation of our customer loyalty and is maintained throughout every department and every stage of production. Put us to the test for your next project and call one of our account managers on 01480 226699 or use our customer enquiry form.

Value added partnerships

We have long working relationships with specialist partners for additional finishing services. These services can range from laser-cutting, plating, anodising and heat treatments which can add decorative finishes, prevent corrosion, and further improve durability.

All additional processes are managed closely and delivered with full transparency and traceability.

start your production journey today

If you are looking to find a complete service including dedicated engineering to design and implement your solution, get in touch with us. You’ll be given an account manager who is always on hand to advise and take care of everything for you. Call us on 01480 226699 or contact us now to see how we can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn and Twitter.

TAKE A LOOK AT OTHER

SERVICES we offer

To find out how we can help you

Get in touch today