3D Simulation For Form Tooling

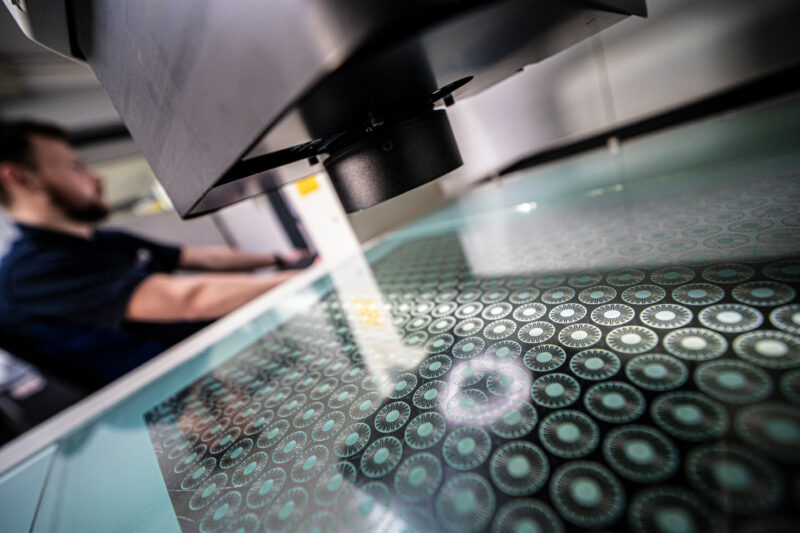

Photofab has developed a new, fully digital, process to design, test and manufacture forming tools.

Historically, form tools would have been manufactured by a skilled tool-maker, on a trial and error basis. Working iteratively, the toolmaker would have needed to form the first blank and take detailed measurements; if incorrect, the toolmaker would have needed to remove more material from the forming tool and try again, checking carefully at each stage until the target measurements have been met.

By digitally designing a form tool using our in-house 3D CAD software, we can now model highly detailed digital forming tools to within extremely tight tolerances. The clever part is that once completed, we can now simulate the use of those models as a forming tool, accounting for material strength, flexibility and any rebound/springback that may take place in the part.

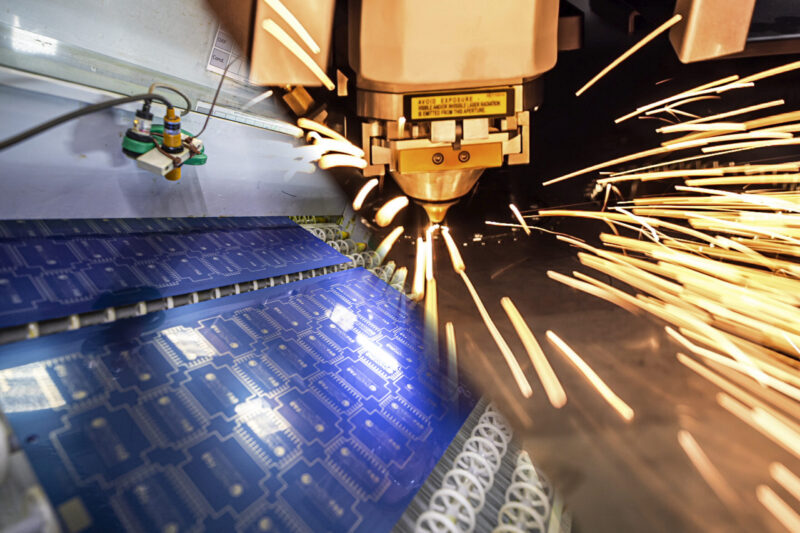

Having passed the simulation tests, we then simply 3D print a high resolution form tool, complete with all details required to form the blank, and then perform a physical test. In the highly unlikely event that the physical test is not within tolerance, we could then quickly and easily refine the digital model, run the simulation model again and re-print a new form tool.

Intended for more complex tools, that require intricate bends and highly precise allowances, the new process has a number of key benefits:

- Offers a linear, right-first-time process, rather than a circular “trial & error” process

- Enables more accurate project scheduling now that trial and error uncertainty has been reduced, if not eliminated

- Delivers more complex form tools, and final components, that would by conventional means been either unachievable or not cost-effective.

In this way we can now work on an even more consultative basis with our clients, by offering even better insight on what is achievable by pairing photo-chemical etching and digital form tooling production.

If you have got to manufacture a sheet metal prototype, or maybe produce a short run of components, then why not contact us now?