Chemical etching vs laser cutting, which one works best?

This is a question we’re often asked as both methods offer cost-effective, precision cutting and engraving of sheet metal, so which one would work best for you?

The key difference is material thickness, anything less than 1.5mm and chemical etching generally wins the day, with new advancements in digital tooling, etching is far more flexible in terms of turnaround, cost, and volume with a consistent accuracy down to 25 microns.

Photofab have been experts in chemical etching for over 50 years offering a broad range of capabilities to ensure the customer gets exactly what they need and when they need it. Working alongside our strategic partners, we can also provide an extremely competitive laser cutting service for those thicker materials. Take a look at both services in more detail and decide for yourself.

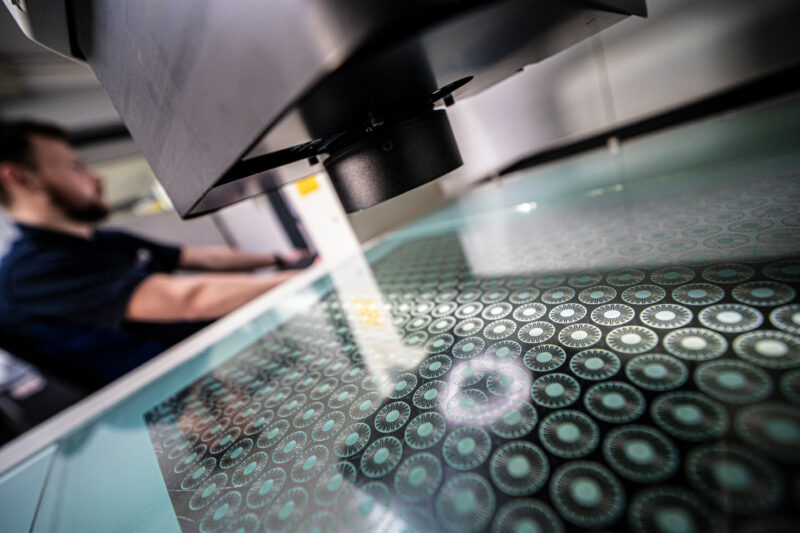

In the red corner: chemical etching

Chemical etching is a machining process for producing precision components which uses acids and other chemicals to erode unwanted metal. From our headquarters, Photofab can work with a wide range of metals, such as brass, copper, beryllium copper, stainless steel, carbon steel and mild steel up to a thickness of 1.5mm.

All in the detail

For quality and precision, chemical etching is still one of the industry favourites, etching maintains incredible tolerances and accuracy, with detail and intricacy that still amazes us.

High volume production

For fast turn-around and mass-production, chemical etching is the perfect choice as many parts can be etched simultaneously, saving valuable time and money. Thanks to our refined chemical etching process, the final pieces are burr-free and leave the material structure completely unaltered, ideal for electrical and electronic applications.

Low volume and prototyping

For prototyping, a combination of digital tooling, automated etching and finishing processes allow for quick and easy design changes to be made, making chemical etching the favoured choice for flexibility and lead-times.

Shaping up nicely

As part of our full-service offering, we also have a dedicated engineering division for forming and finishing with a stock of 1000’s of hard tooling to cover a multitude of shaping requirements. If there are bespoke forming requirements, we can also manufacture specific tools in-house to drive down costs and speed of turnaround.

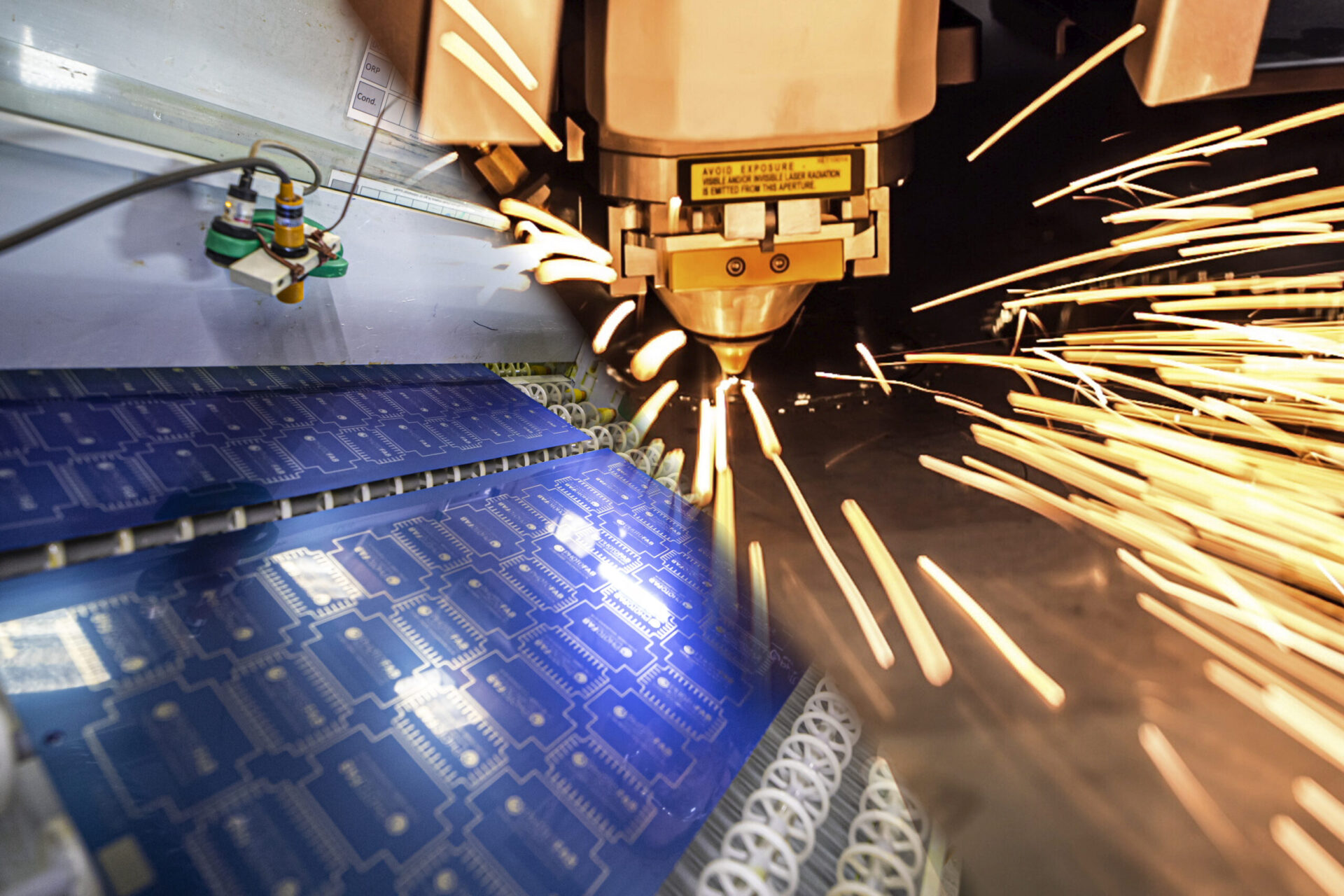

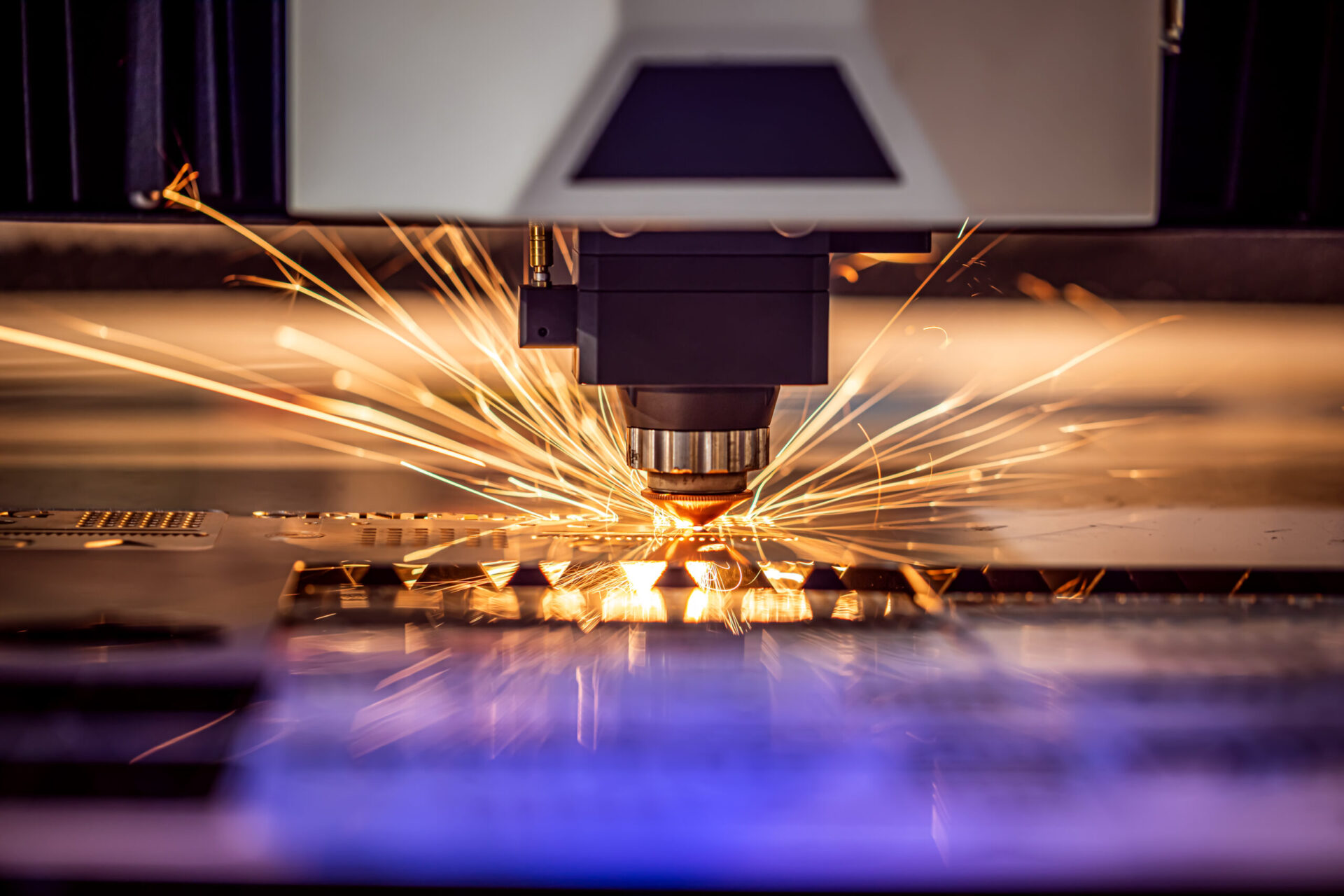

In the blue corner: laser cutting

Laser cutting does exactly what it says on the tin: uses a laser to cut through metal. The process works by directing the output of a high-power laser through the metal, which will either burn, melt or be blown away by a jet of gas, leaving the edge with a high-quality surface finish.

Pin-point accuracy

The precision of laser cutting is a key factor, as the laser beam does not wear away during the process. This results in laser cutting providing highly complex designs that are ideal for short run jobs, rather than high volume mass production. Simply put, if you are seeking a solution for small volume work over 1.5mm, laser cutting is the perfect technique.

Thick as you like

Well, up to 22mm anyway, laser cutting is by far the favoured method for thicker metals and provides great accuracy on a large range of metals, which can be highly cost effective and offers short lead-times. Perfect for lower volume production over 1.5mm thick.

Red or blue Photofab is always the best choice

Thanks to Photofab’s capabilities and supply chain management, whichever route you choose, you are guaranteed a great service. From prototyping to mass production, using Photofab’s in-house chemical etching service provides the perfect choice for precision and short lead-times for sheet metals under 1.5mm thick. For precision and low volumes over 1.5mm, laser cutting is the better option, reassuringly managed and quality controlled by Photofab to the exact same high standards.

No matter what you choose, all of our processes follow SC21, ISO9001, 14001 and 45001 with full traceability along the way. Our experience, coupled with our vast range of industry leading equipment and trusted network of partners makes Photofab the perfect choice for precision manufacturing, whatever your requirements.

Production is only a quick call away

Call one of our dedicated team of account manager’s today or contact us now to see how Photofab’s chemical etching and laser cutting services can give you the results you are looking for. You can also keep up to date by following us on LinkedIn and Twitter.