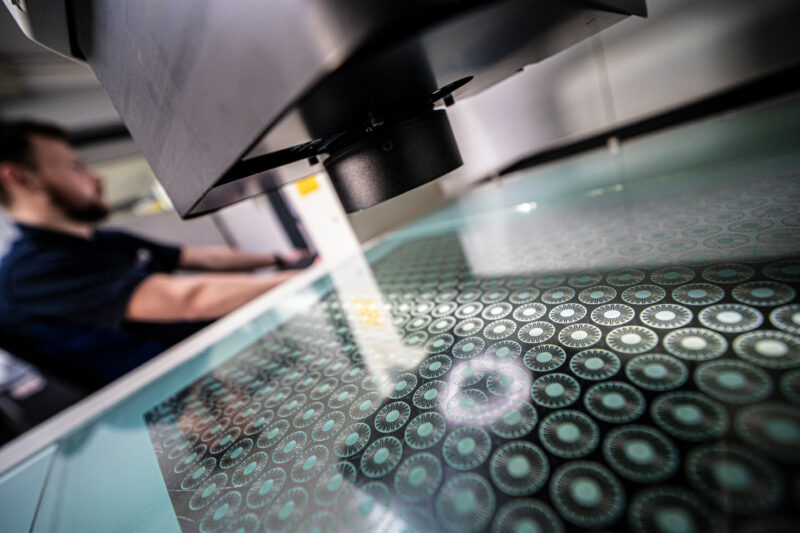

Delivering precision etching for leading medical component manufacturers

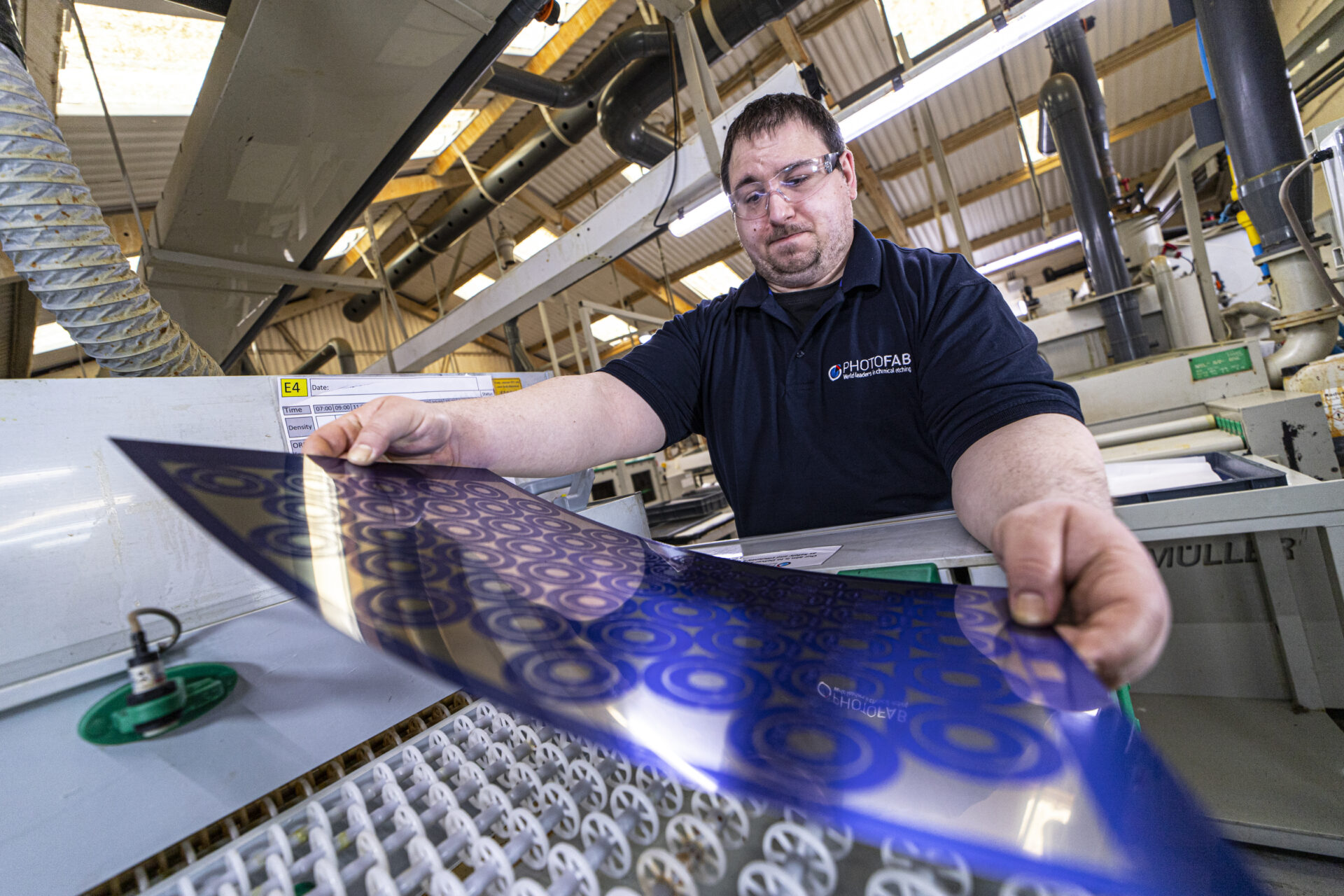

The medical sector is constantly evolving. Getting essential medical components to market quickly and reliably is critical. That’s why leading medical device companies partner with Photofab for high-precision etched parts. Our refined chemical etching process consistently produces outstanding quality components, giving you greater control over the parts you need for your next life-saving innovation in the medical sector.

Outstanding consistency and burr-free.

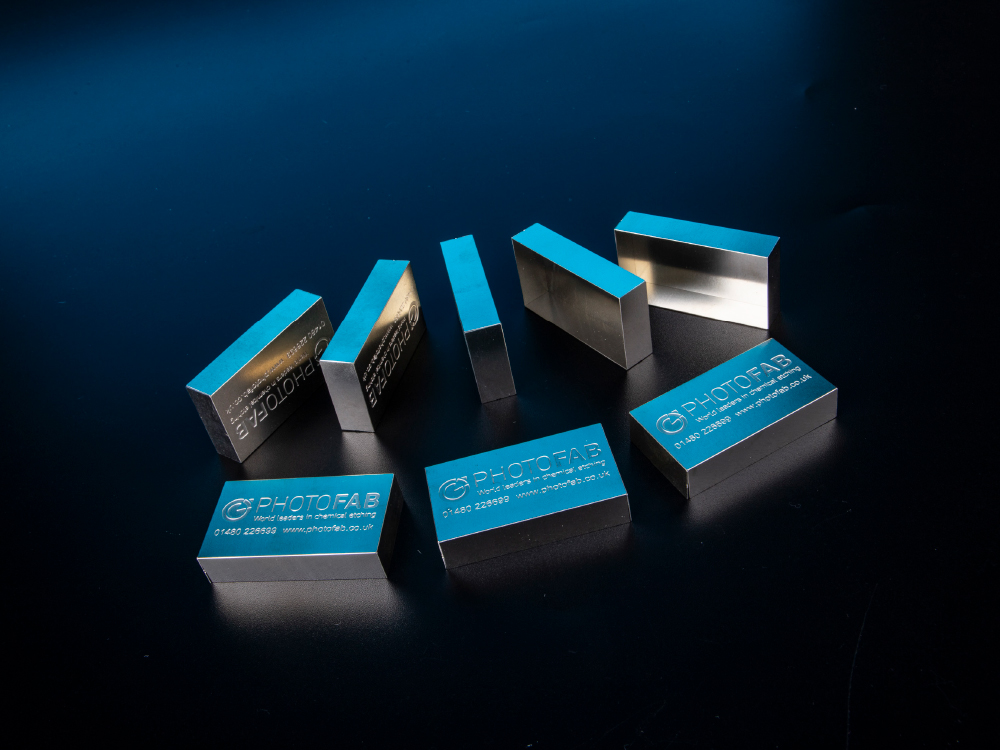

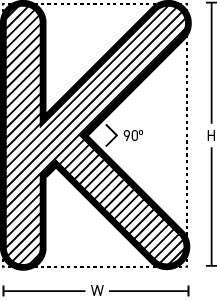

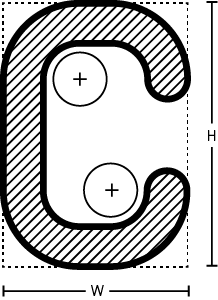

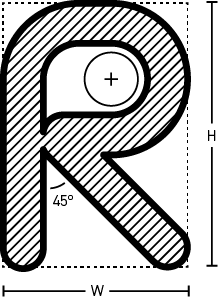

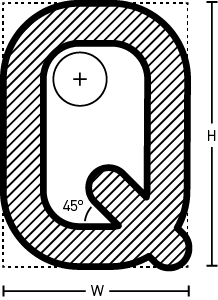

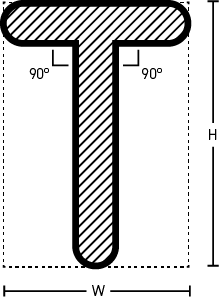

Chemical etching uniquely leaves the internal metal structure unchanged and does not affect metal properties like hardness, grain structure, or ductility. This ensures accuracy and consistency with original specifications – essential for medical devices where quality is paramount. Combining this with the precision of chemical etching to +/- 25 microns and a burr-free finish makes it the ideal manufacturing process for medical production.

SPEED

PRECISION

COST-EFFECTIVE

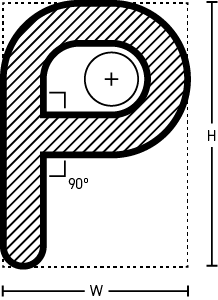

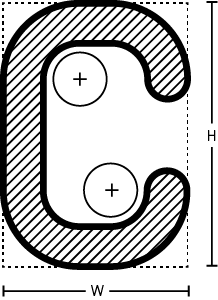

Typical medical components we manufacture:

- Surgical/bone saws

- Medical implants

- Mesh

- Shims for virus testing kits

- Clips for face masks

- Respirator parts

- Blood filtration devices

Full-Service Support for Your Product Journey.

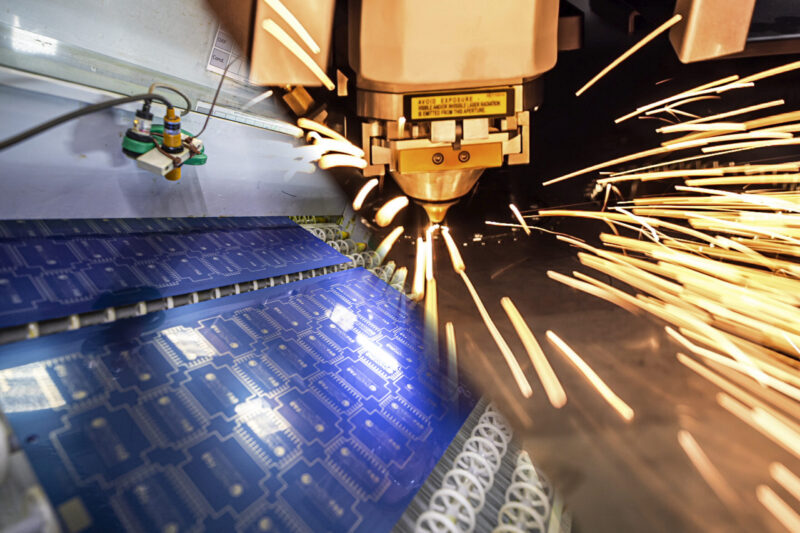

We also offer complete production services from digital tooling to volume manufacturing. Our process refinement over decades creates highly efficient, quality, and cost-effective services. Our prototyping and volume production are managed to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze standards with a single point of contact throughout. Our in-house secondary engineering services also let customers outsource etching, forming, finishing and assembly. This combination of flexibility and full-service is ideal for taking concepts through to mass production.

All of this puts us in the ideal position to assist in production for the medical sector, where our expertise is regularly relied upon to make the difference.

The key difference.

We pride ourselves on the technical quality and high standards of customer service. Every order is assigned to an Account Manager who will be on hand to assist until order completion. It’s this customer-focused service that has led to our high levels of customer retention.

Trusted when it matters most.

The Covid pandemic created an environment where the rapid manufacture of essential medical equipment became the number one priority for the companies supplying the NHS. Photofab were proud to assist by producing, with priority, a range of components essential to ventilator equipment, using our class-leading etching and the expertise of all of our staff.

We are fully set up to provide precise and rapid manufacturing for components in medical devices, having proven ourselves capable when it mattered most for the medical sector.

Why work with us?

We are renowned for their industry leading customer service, where our dedicated account managers are your expert single point of contact. Supporting you with anything from technical and design questions through to quotes, orders, delivery, and everything in between. We strive to offer the best customer service experience in the industry. We take immense pride in being able to push the boundaries of chemical etching with our commitment to continuous improvement.

KNOWLEDGE

Over 55 years of expertise and experience with a highly trained team of specialists delivering high volume orders.

CAPACITY & SPEED

For cost-effective full volume orders of hundreds of thousands. We also offer fast turn-around, as little as 24 hours.

SERVICE

Our dedicated account managers are experts and there to help, advise and manage.

RELIABILITY

Trusted by thousands of OEMs to deliver quickly and accurately.

QUALITY

SC21, ISO 9001, 14001 & 45001 quality processes.

TRACEABILITY

Fully traceable materials and processes.

What materials can be etched?

We offer an extensive range of metal types and thicknesses, all with full traceability. Various hardness are also offered to meet your requirements. Metal stocks are kept at levels that enable Photofab to offer rapid service to meet the needs of this fact paced industry.

Stainless Steels

Austenitic (301, 302, 304, 316, S526, S527), Martensitic (321, 410, 420), Precipitation Hardened (17/7), Heat Resisting (309, 310)

Other Steels

Mild Steel, Carbon Steel, Tool Steel, Spring Steel, Transil, Losil.

Nickel Alloys

Nichrome, Mu Metal, Nickel Copper (70/30), Inconel, Nickel Brazing Foil.

Nickel/Iron Alloys

Invar, Alloy 42, Kovar, Radio Metal.

Copper

Tough Pitch 101, Oxygen free – High Conductivity.

Copper Alloys

Brass, Phosphor Bronze, Beryllium Copper, Nickel Silver, Ferry Constantan.

Aluminium and Aluminium Alloys

Silver and Alloys

Silver, Silver Alloys, Silver/Copper, Silver/Palladium, Silver Brazing Alloys.

Trust our capabilities for medical applications

We enjoy high customer retention in the medical sector. Our dedicated Account Managers ensures personal service and pride in our quality and reliability. See the difference for yourself for your next medical project.

You can also follow Photofab on LinkedIn for more updates.

To find out how we can help you