Embracing Apprenticeships in engineering

Apprenticeships have long been a cornerstone of engineering, providing hands-on training and practical experience to develop real-world skills and knowledge whilst working towards a qualification. Apprenticeships bridge the gap between learning and earning, which help shape successful careers as well as the practical advantages for the business growth and innovation.

Our apprenticeship history

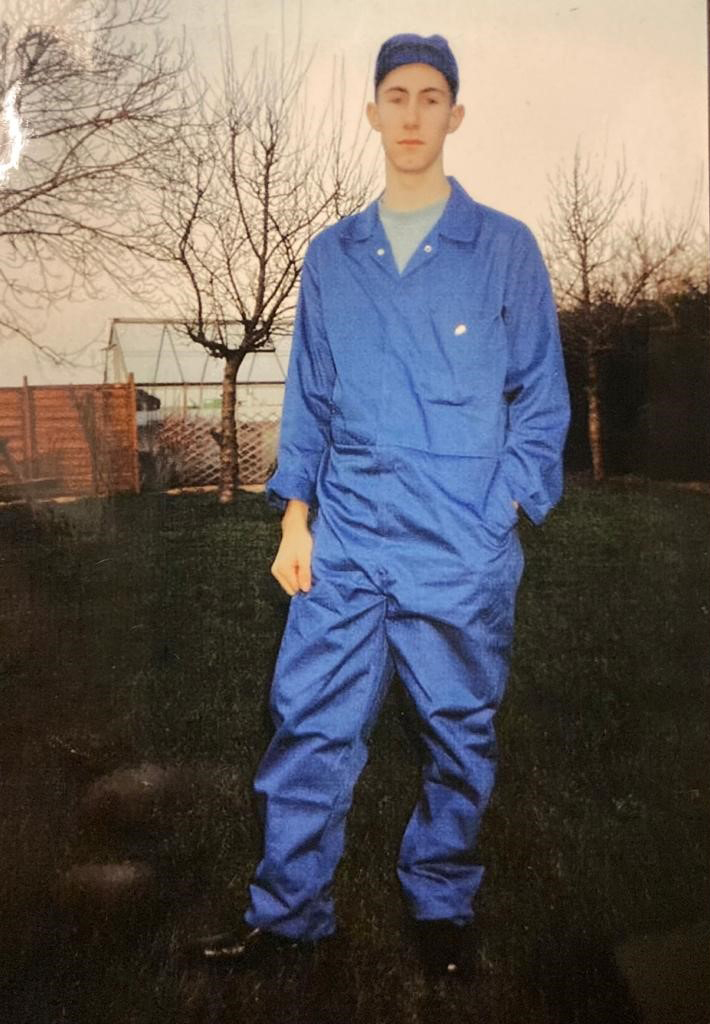

We have enjoyed a long history of apprenticeships and developed some incredible successes including our very own Managing Director Neil Shorten and Operations Director Paul Rea.

Josh Roberts started his apprenticeship in 2013 after completing his A-Levels. Josh worked alongside our experienced team in all sections of the business, learning the practical and technical elements of our products and services. Josh commented “Throughout my apprenticeship I was encouraged to be involved with activities in relation to Right First Time, Data Logging and Scrap Reduction Projects while learning the core production aspects of the business. Through being involved in these activities and finding an interest in the metrology side of quality inspection I began to build a role within the company leading me to become and auditor, then an assistant quality manager and finally in 2022, Quality Manager.”

He continued “Now 10 years on I have been able to visit parts of the world I had always wanted to, buy a house, and start a family with my wife all while being encouraged by the company to not only pursue my growth in the business but within my personal life as well.

I would highly recommend to anyone that is looking to build a career to look into apprenticeships even if they aren’t sure what field they would like to go into, it was one of the best decisions I ever made!”

Today’s apprenticeship.

In 2023 Connor Payne joined us and is gaining practical experience in real manufacturing processes and having a day release to college studying a Level 3 NVQ in Engineering Design and Draught person. Connor commented “I worked at Photofab before as casual work but was looking to further my education and still earn a wage. Photofab offered me the opportunity to learn a new skill and work on their apprentice scheme.”

He continued “This has given me the opportunity to work in various departments within the manufacturing processes whilst going to college once a week to gain a qualification, I’m picking up many new skills and meeting a lot of new people in the workplace that I wouldn’t have gained in full time education.”

Why choose an apprenticeship?

Practical Learning and Hands-on Experience

Apprentices gain practical skills by working alongside experienced professionals, tackling real engineering challenges, and participating in actual projects. This experiential learning approach fosters a deeper understanding of the field, equipping apprentices with the skills and confidence required to excel in their future engineering careers.

Mentorship and Guidance

This provides a unique opportunity for aspiring engineers to learn directly from seasoned professionals who can offer invaluable insights, industry knowledge, and practical wisdom that cannot be gained anywhere else.

Enhanced Employability

The hands-on experience obtained during apprenticeships provides a competitive edge, as well as the opportunity to network and build professional connections, which can lead to future job opportunities.

Industry-Relevant Knowledge

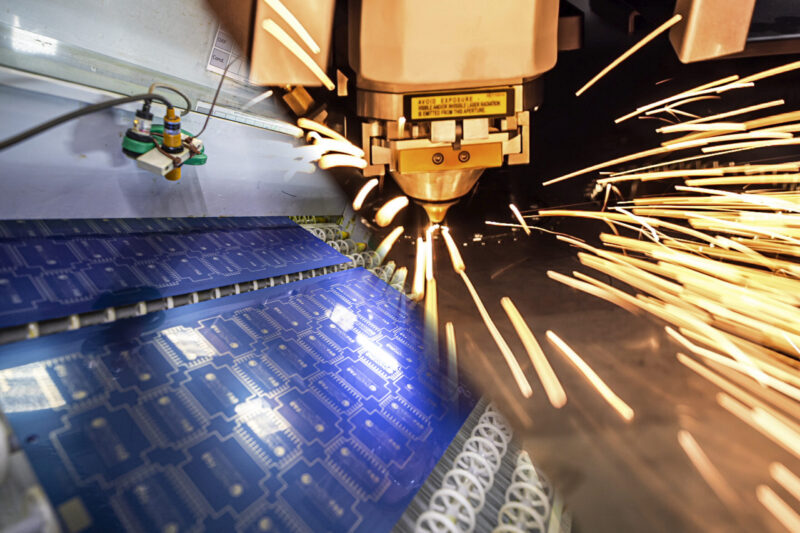

The engineering field is constantly evolving, with new technologies, techniques, and best practices changing all the time. Through their involvement in real projects, apprentices become familiar with the latest engineering trends and innovations, gaining a practical understanding of how these advancements are applied in the field.

Financial Benefits and Reduced Debt

Unlike college and university education, apprentices typically earn a salary while they learn, allowing them to support themselves financially and potentially reduce the burden of student debt.

Why choose us for your apprenticeship?

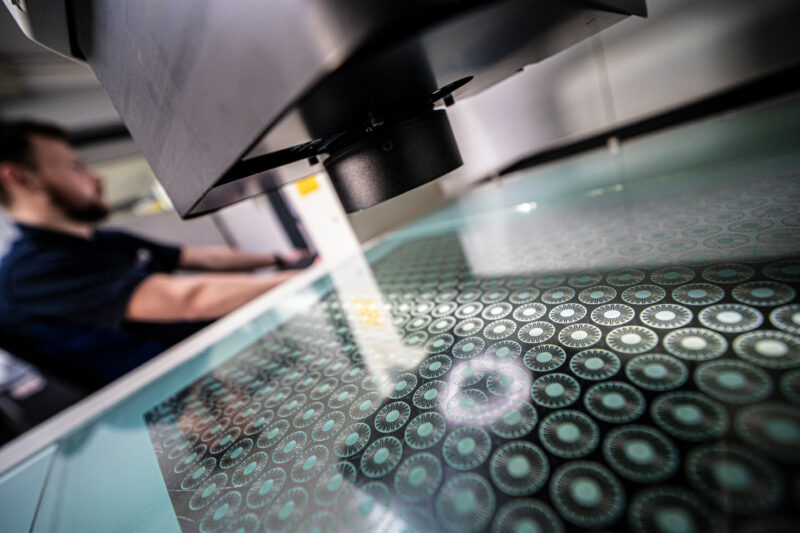

For over 55 years, we have been world leaders in chemical etching and engineering services, making considerable investments in both technology and our people to futureproof our success. Having attained the Investors in People standard, we recognise that by empowering our employees, we will provide a better service to our customers and ensure stability and growth for all.

Our people are the beating heart of the business, supporting each other to provide the best possible service from start to finish, and as a full-service provider with 2 dedicated facilities, we can offer a multitude of career options.

Your future starts now.

We offer a multitude of career progression opportunities, tailoring a variety of programmes to suit individuals. Having produced over 80,000 intricately shaped components across over half a century in business, we know a thing or two about manufacturing and engineering. We have all the necessary ingredients available for you to kick start a career in the manufacturing industry. From administration and logistics to chemical etching, forming and tool making, the opportunities are endless and there is no better time to apply.

Join the Photofab family.

Join a company that values their workforce and offers a multitude of benefits and career options. Visit our careers page to explore our latest opportunities, contact us now to find out more or join us on LinkedIn for the latest updates.

To find out how we can help you