Experience fast and efficient turnaround

Time is of the essence when it comes to working with customers. Whether you are a business owner, a designer, or an individual looking to bring your creative ideas to life, having a reliable and efficient manufacturing partner is crucial. That’s where we come in.

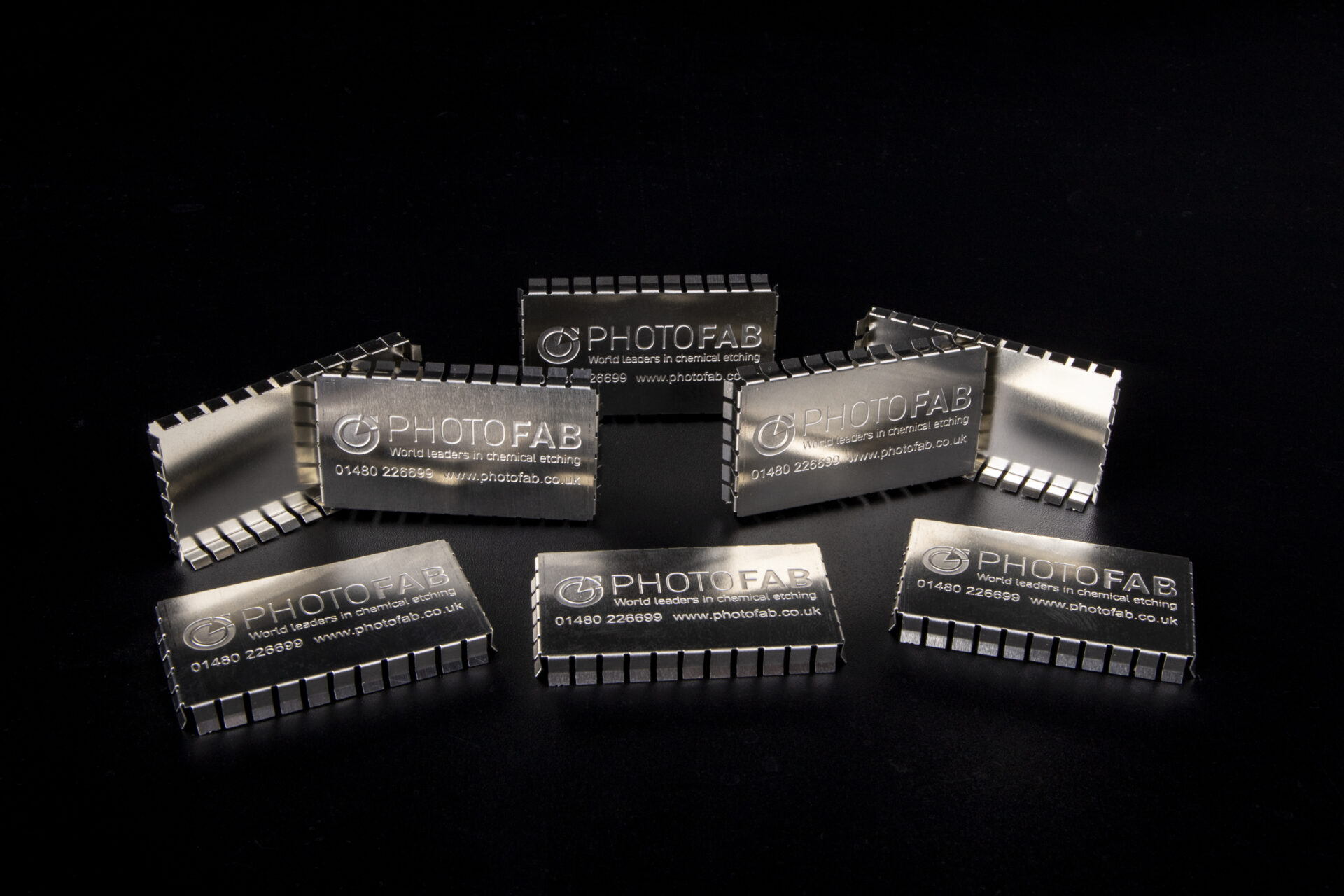

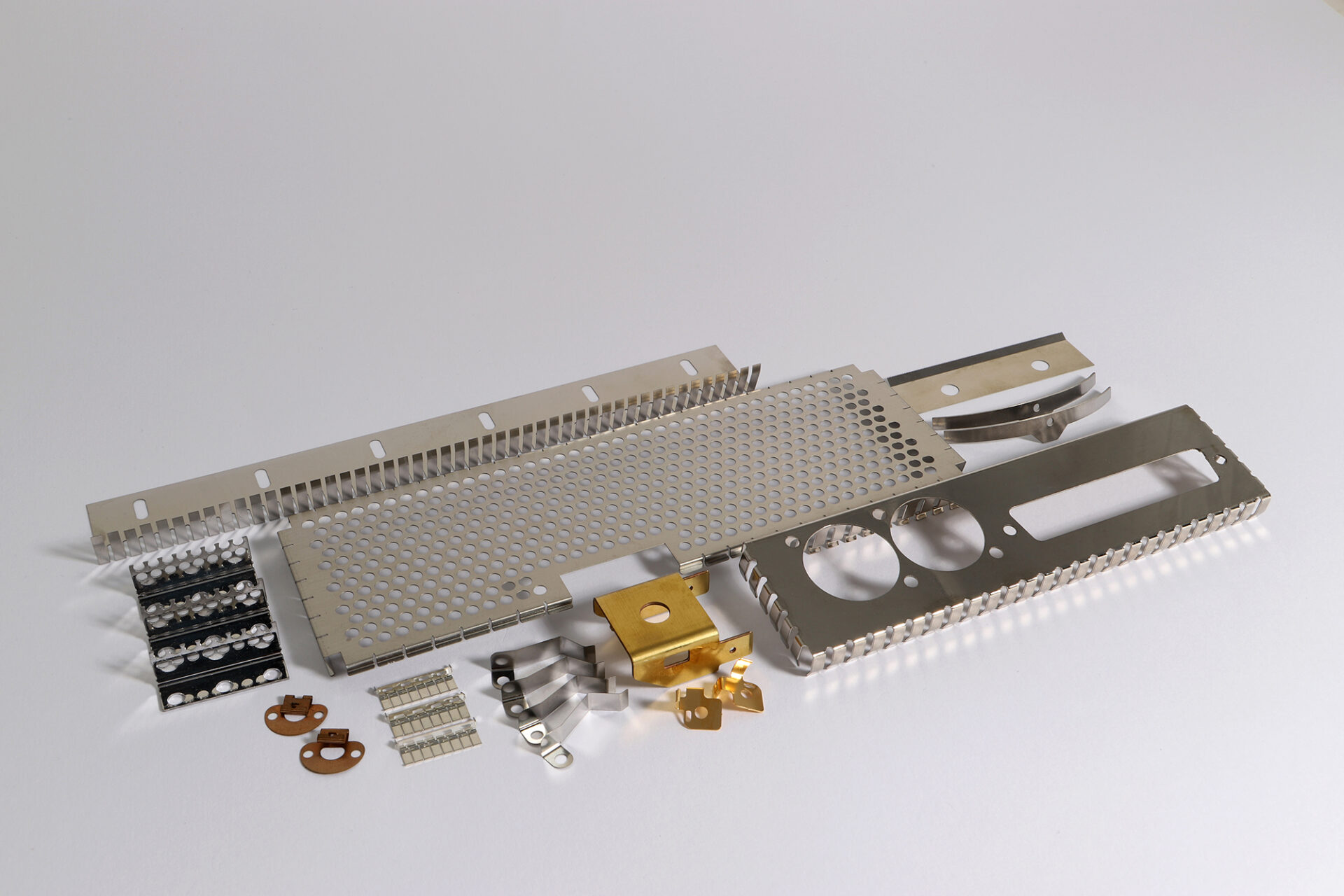

With our unwavering commitment to quality, precision, and quick turnaround times, we are the go-to choice for all your chemical etching needs. The company’s rapid turnaround service has long been a key selling point for many years. Speed of production is a large part of our success story, whether the products are battery contacts, connectors, gaskets, complex diaphragms or more!

Unparalleled precision and delivery times

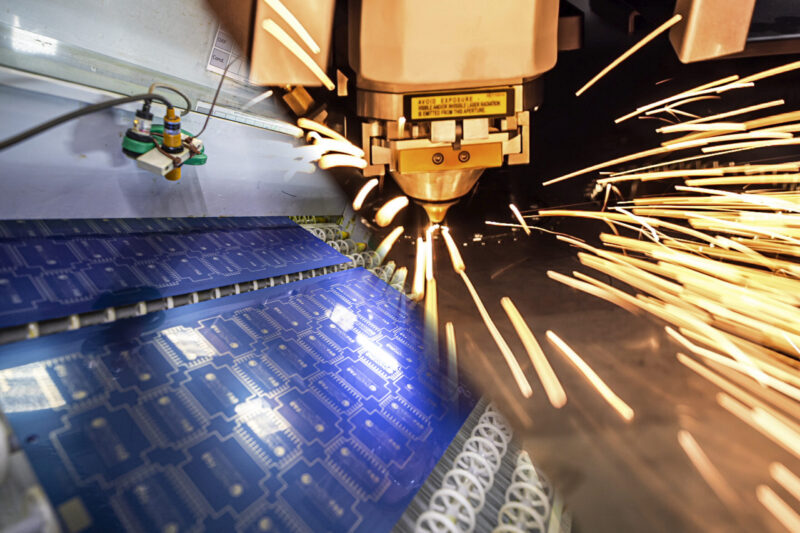

As a leading manufacturer specialising in the production of high-quality precision metal components, we have established ourselves as a trusted name in the manufacturing world. With state-of-the-art facilities and advanced technologies, we are able to deliver exceptional results with unmatched speed and accuracy.

When it comes to manufacturing, precision is key. We understand the importance of accuracy in every component produced, but also, delivering it within a timescale that suits our customers.

For standard chemical etching projects, quotes are provided within 24 hours. Our expert team will often be able to provide even faster turnarounds when needed to meet a customer’s urgent requests. Quick response times are our specialty – put us to the test and find out!

Quality is never compromised

In addition to rapid quotes, our team maintains rigorous quality control processes, including full traceability of raw materials and thorough documentation procedures, at every stage.

Our quick-turn chemical etching has long allowed customers to rely on us for fast component production. Whatever component you need, whether it’s battery contacts, connectors, gaskets, diaphragms or other precision parts, our digital tooling enables us to swiftly deliver one-off prototypes or short runs.

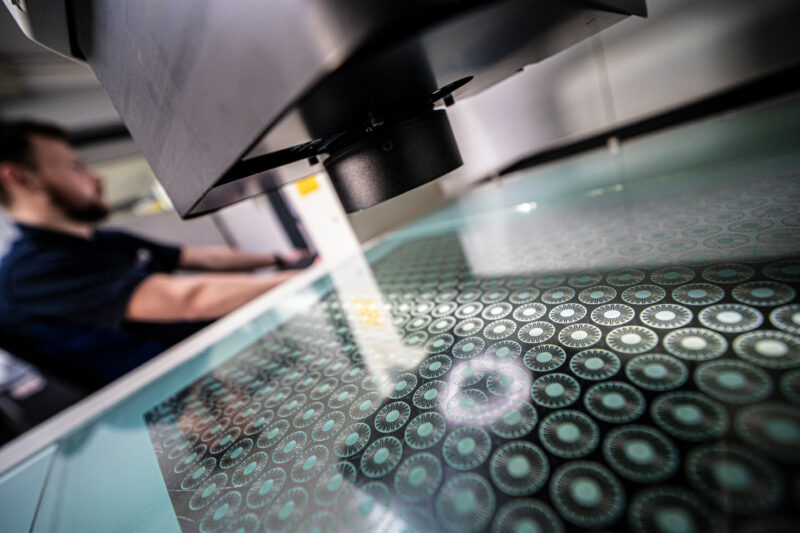

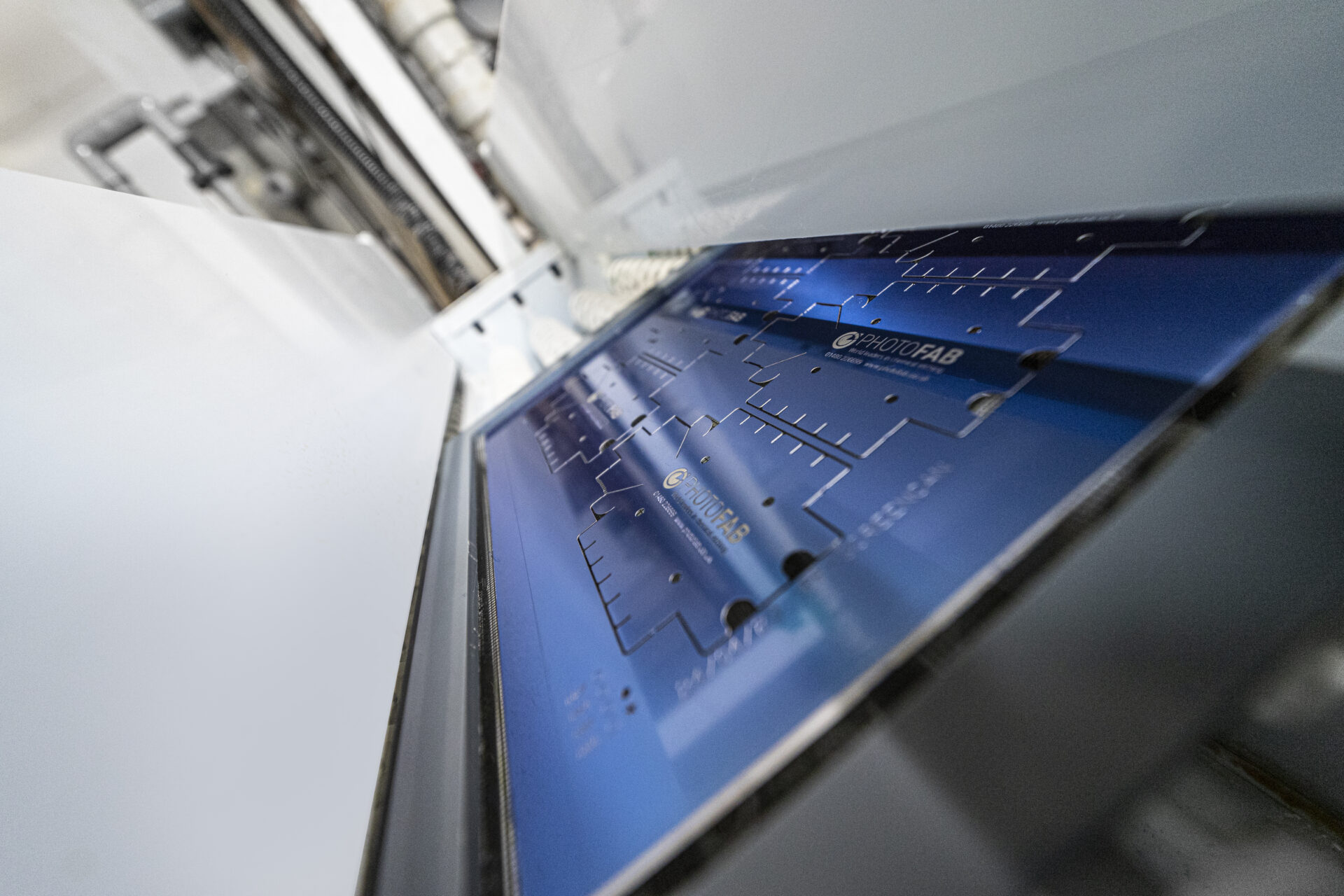

These agile digital tools consist of easy-to-update electronic files that give us maximum adaptability. We can translate designs to any grade of sheet metal from 0.01mm to 1.5mm thick with ease, and we can fit multiple designs on a single sheet for efficiency.

Certified and ready to go

We also have a rigorous quality assurance process in place to ensure that every component meets the highest standards. From material selection to final inspection, every step of the manufacturing process is carefully monitored and controlled. This commitment to quality has earned the company ISO 9001 certification for Quality Management, further solidifying the company’s reputation as a reliable and trustworthy manufacturing partner.

Complimenting this certification, we demonstrate rigorous product quality standards as well as high levels of customer service, which are proven through its SC21 certificate and ISO 45001 and 14001 certificates.

We create comprehensive process documents for every job that allow us to repeatedly achieve excellent standards and maintain full traceability of materials. This rigorous attention to detail is what enables us to reliably deliver high-quality components, time and again.

In addition, our rapid prototyping and production capabilities are backed up by hard proof – we track delivery statistics to validate our quick turnaround times for rush orders. Customers can trust that when we commit to fast delivery for urgent projects, we have a proven ability to fulfil that promise.

Keep an eye on the blog series

Keep a close eye on the news section and LinkedIn for content in the coming weeks and months detailing our rapid turnaround service and the nuances that make it a reality.

If you wish to learn more about our expertise and how you can benefit from the capabilities and services detailed in this blog, use the contact page to tell us what you need and a member of the team will get back to you as soon as possible.

To find out how we can help you