Photofab automates faster lead-times

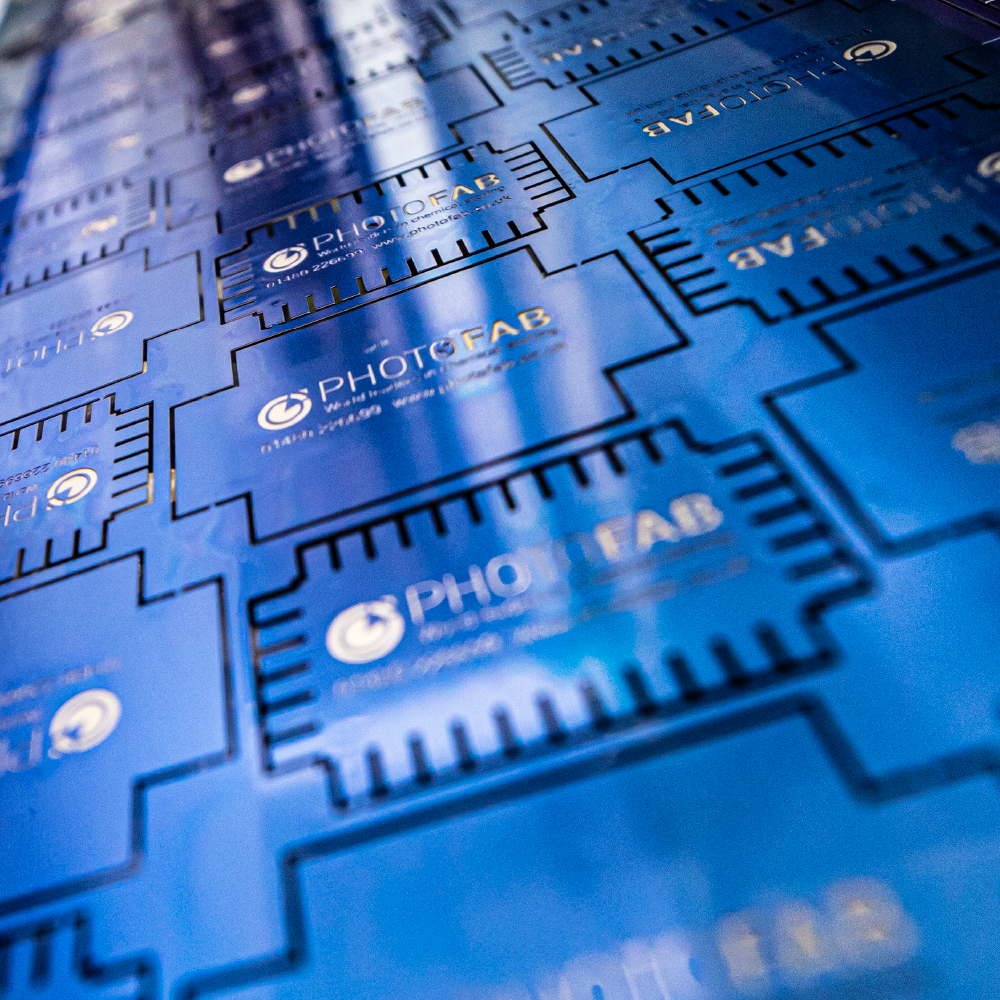

Building on our 50 years’ experience and continuous investment in people and processes, we have evolved our high-volume chemical etching services to deliver industry leading standards in both quality and lead-times.

This new level of production has been made possible with the latest digital and automation technology, from our flexible digital tooling capabilities through to automated lamination, all closely monitored and checked through our ERP system, delivering both speed and quality.

A partnership of speed and control to drive down costs

Utilising our automation measures throughout the process ensures the speed of high-volume orders can still maintain the highest standards in tolerance and consistency.

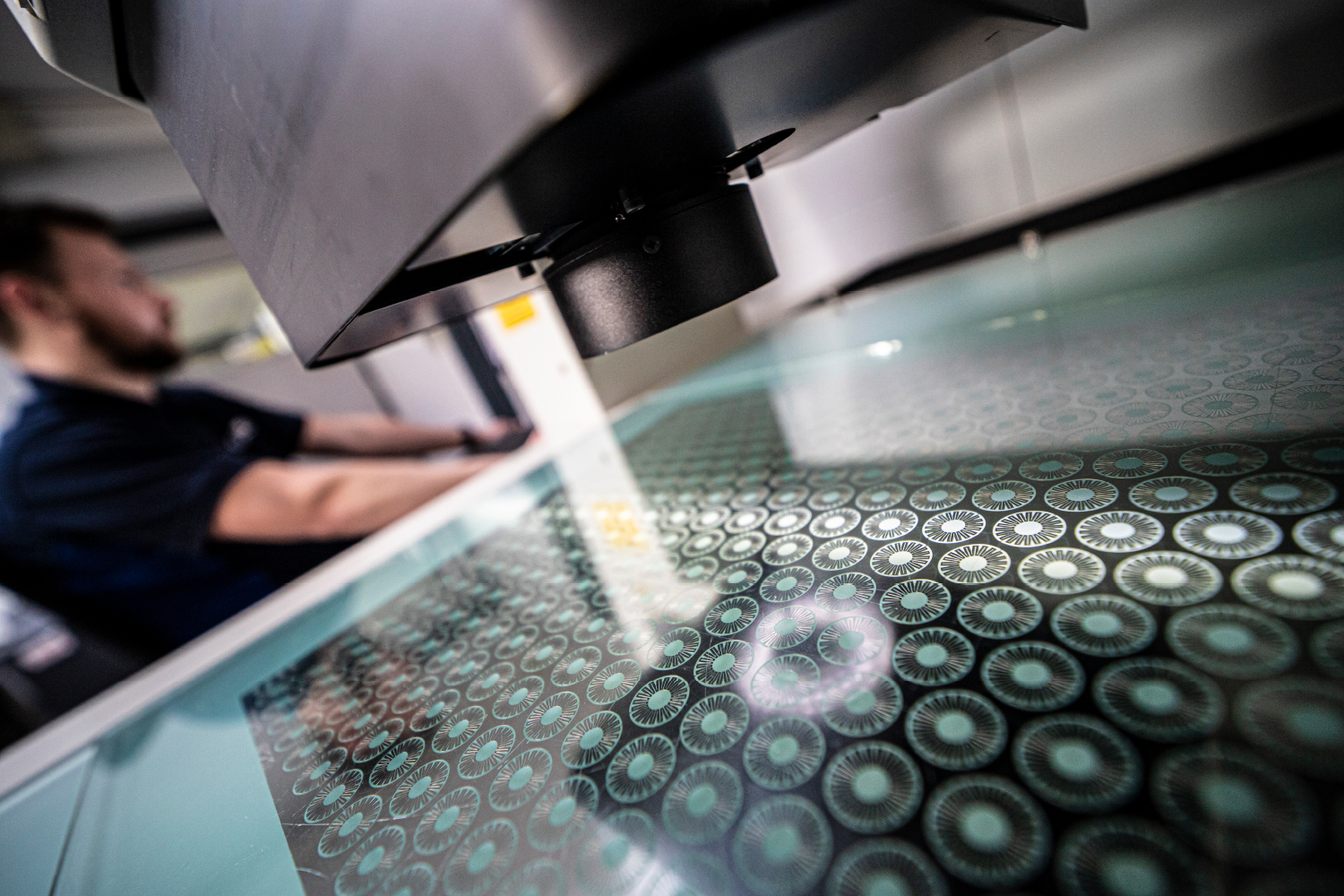

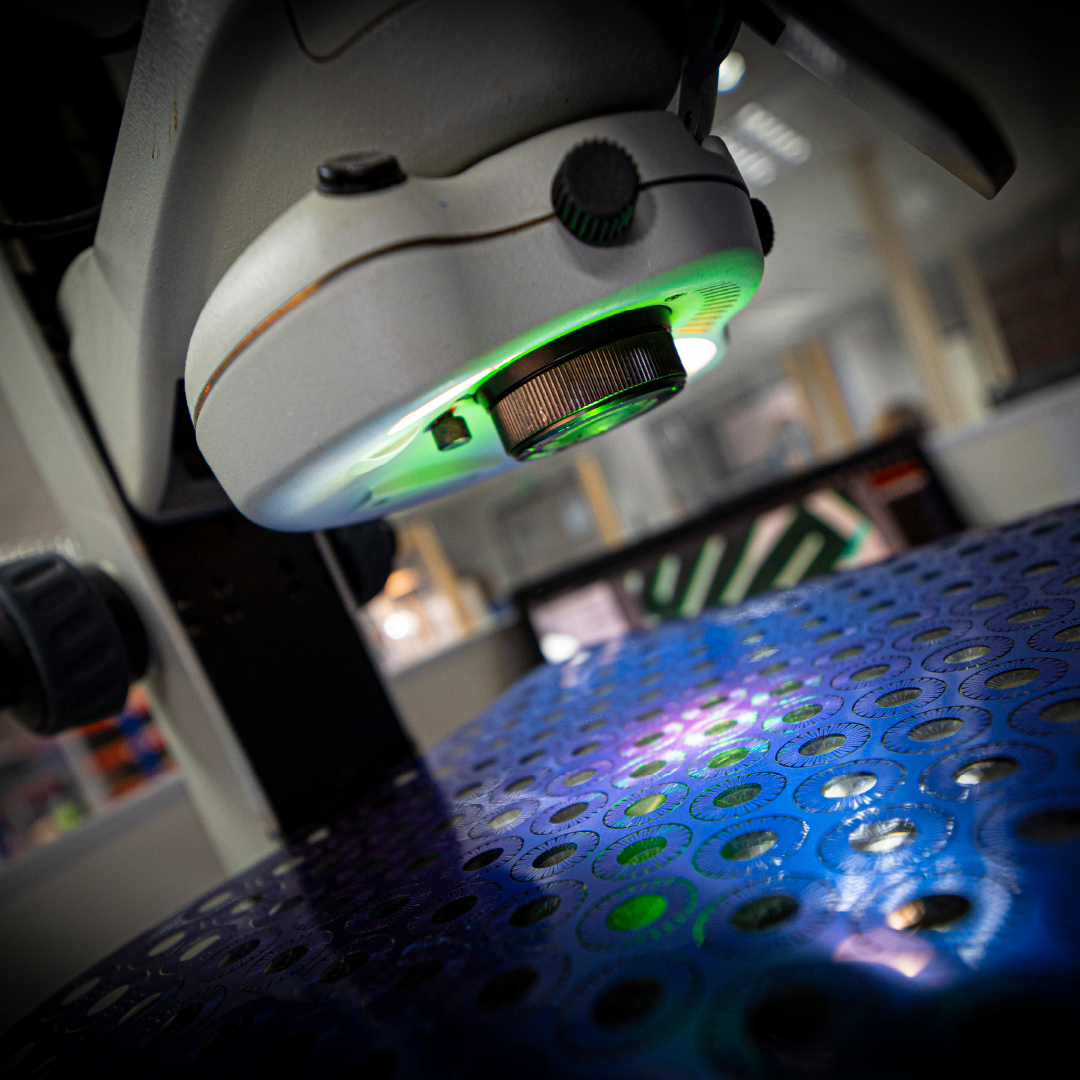

Starting with our automated plotter, which produces fast and accurate digital tooling in just 30 minutes. Remote digital files can be sent direct, making it highly cost-effective and fast to make any design changes.

Investments in material preparation and printing room have already shown tangible improvements to quality and speed, with orders reaching the etching team far sooner.

Our chemical etching department houses five etching machines, all with multi-chamber etching capabilities for faster etching on thicker materials. This is all supported by our production team, who are highly experienced in high-volume orders.

With further automation capabilities in metal stripping, measurement and logistics, orders are ready for forming, assembly and finishing or shipped direct to our customers, maintaining our 98% OTD service. Want your order even faster? Talk to us about our Rapid Manufacturing Service.

The devil is in the detail

Speed is nothing without control, and quality is the key to our ‘World leaders in chemical etching’ strapline. Along with our ERP (Enterprise Resource Planning) system to monitor and control order progression, quality control checks are made at every stage to ensure our high standards are met and strict tolerance control is maintained throughout.

Achieving the SC21 bronze award for maintaining 98% operational excellence across our entire production process for seven years in a row is a testament to our success, reinforced by our ISO 9001 for quality, ISO 14001 for environmental management and ISO 45001 for the worldwide standard in health and safety management. Quality assurance is one of the many reasons customers trust Photofab as their preferred manufacturing partner.

Not only, but also

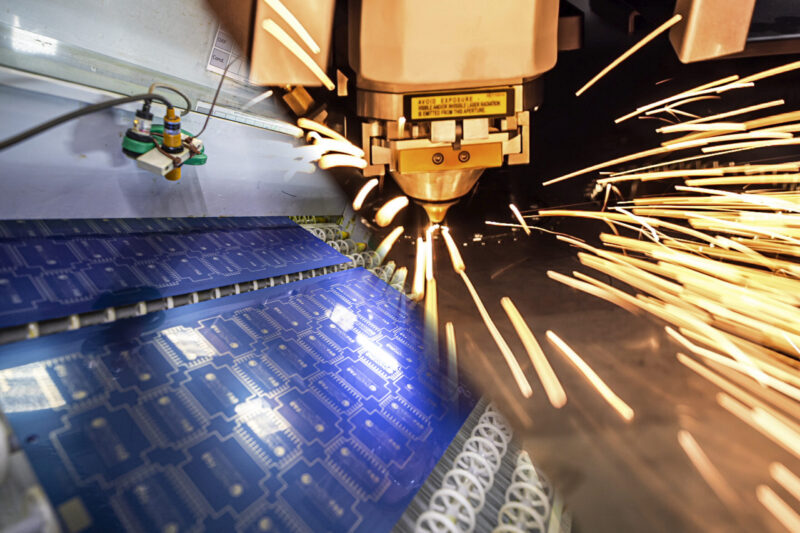

Photofab continuously invest and innovate to improve our service offering and have recently opened a dedicated engineering unit for tooling, forming and finishing. We also have close working relationships with specialist partners for additional manufacturing services, ranging from stamping and laser-cutting to plating, anodising and heat treatments. All additional processes are managed closely and delivered with full transparency and traceability.

Service with a smile

Our capabilities and automation have created an industry leading standard in all levels of production from prototyping to high volumes, but the Photofab service is led by its people, with good old-fashioned customer service, knowledge and expertise. From your own dedicated account manager through to our logistics team, we are always on hand to help, advise and take care of everything for you.

Call our account team today on 01480 226699 or contact us now to see how Photofab can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn and Twitter.