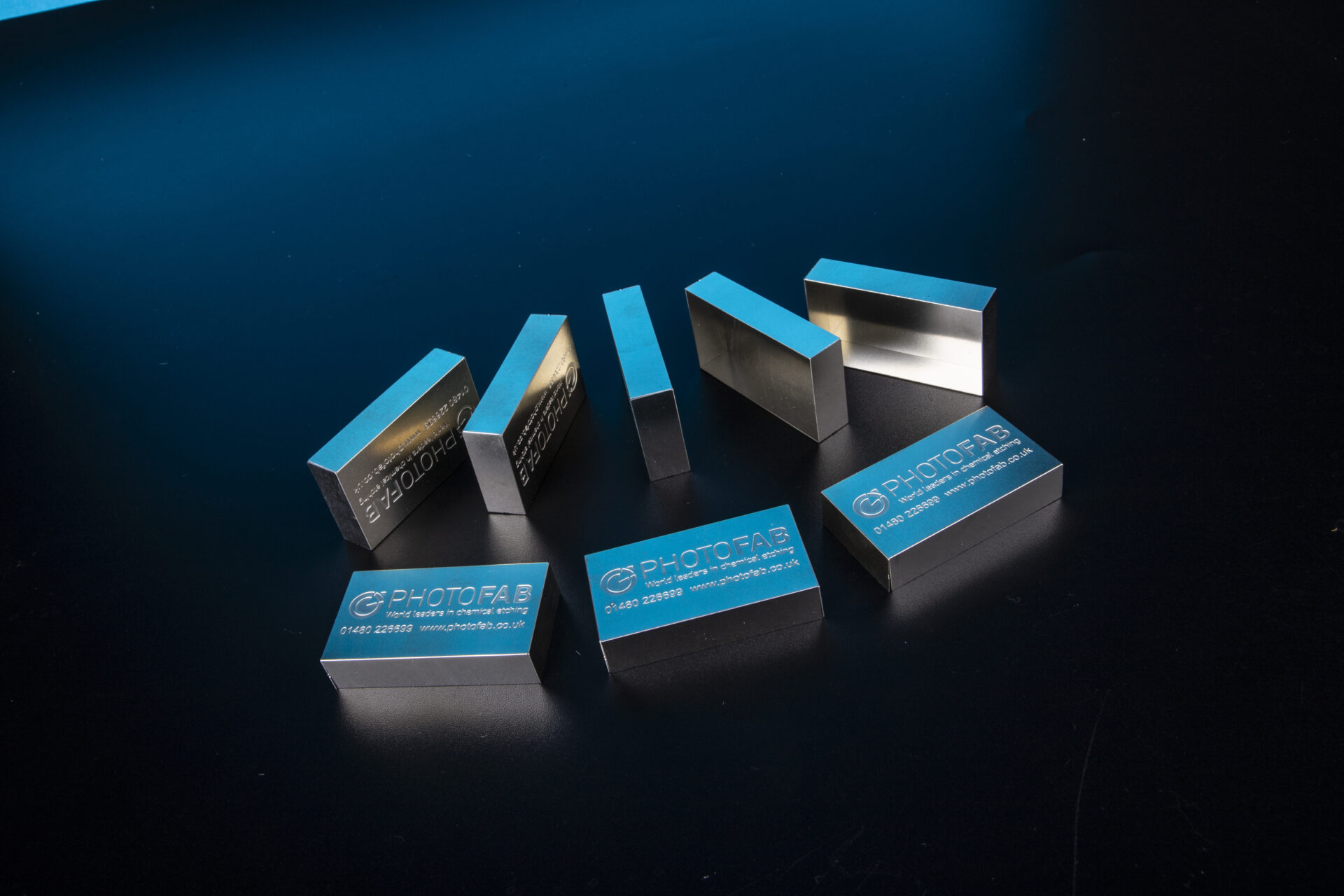

chemical etching powering the electronics sector

The electronics industry moves fast. Getting intricate components to market quickly and cost effectively is essential. That’s why leading UK electronics companies are reshoring their supply chain with us for flat metal and formed components. Our refined etching process consistently delivers high-precision parts with outstanding quality, giving you greater control on the parts you need to complete your next project.

Why choose chemical etching for your components?

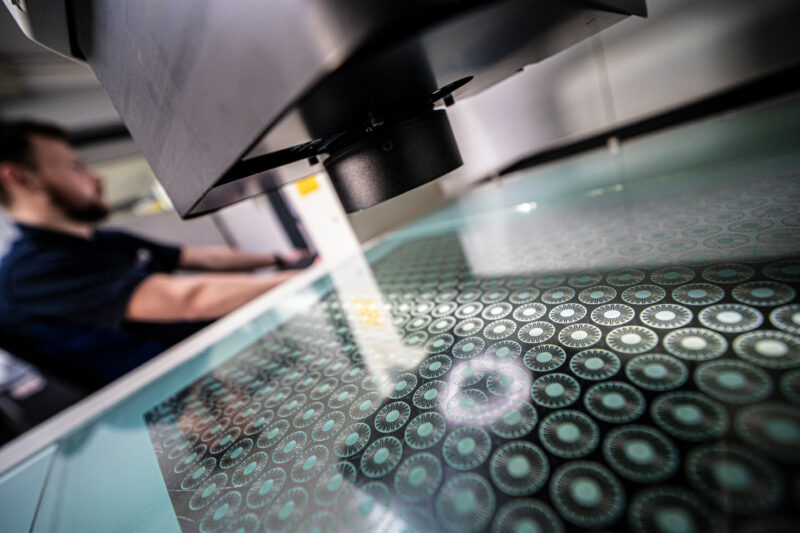

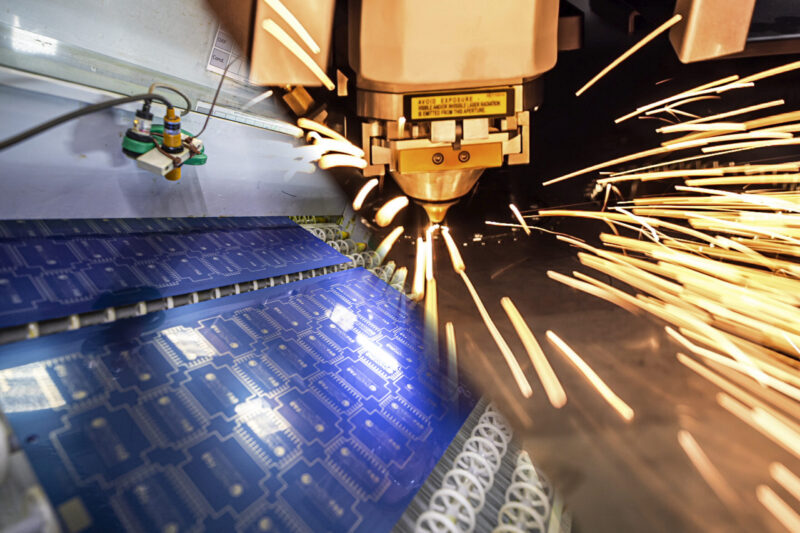

Chemical etching carries the unique advantages of leaving the internal structure of the metal unchanged. Neither does it affect the properties of the metal with regard to hardness, grain structure, or ductility of the metal. This is critical for electronic components to ensure accuracy and consistency of the original specifications. Combining this with the +/- 25 micron precision of chemical etching and a burr-free finish makes this manufacturing process ideal for electronics production.

SPEED

PRECISION

COST-EFFECTIVE

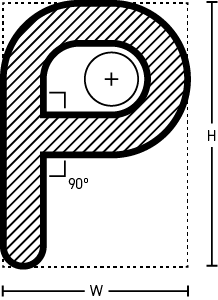

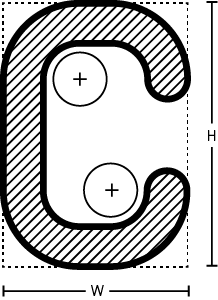

Typical components we manufacture are:

- Lead frames

- EMI / RFI shielding.

- Semi-conductor cooling plates

- Connectors + Contacts

- Shims

- Gaskets

- Spacers

- Springs

Supporting your entire product journey

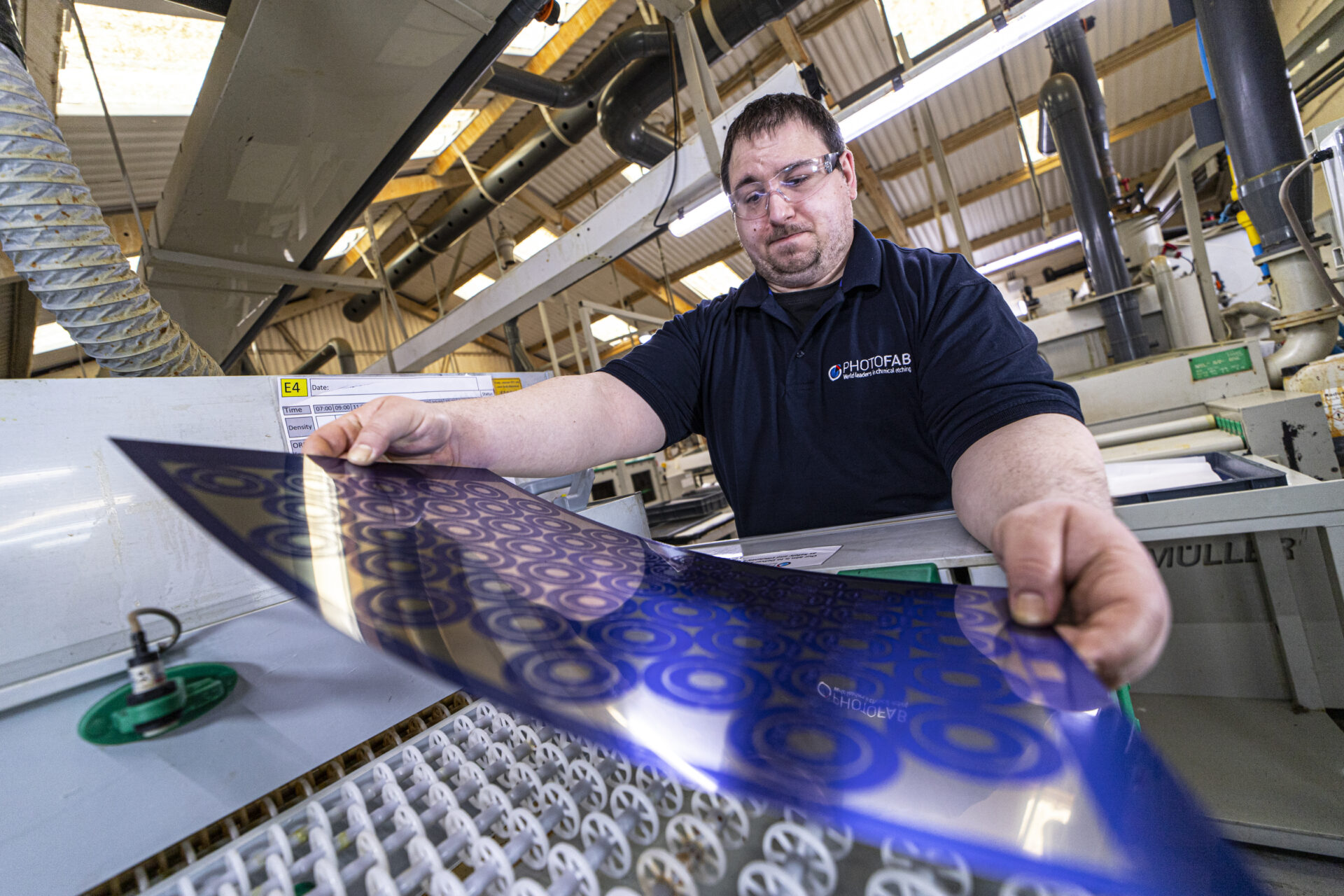

We offer full-service production from digital tooling through to volume production. Our process has been refined over decades to create a highly efficient, quality, and cost-effective service.

Our rapid and flexible prototyping through to volume production and forming services are all managed to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze accreditations with a single point of contact throughout. Our secondary engineering services also allow customers to outsource etching, forming, finishing, and assembly. This flexibility and full-service approach are ideal for taking concepts to mass production.

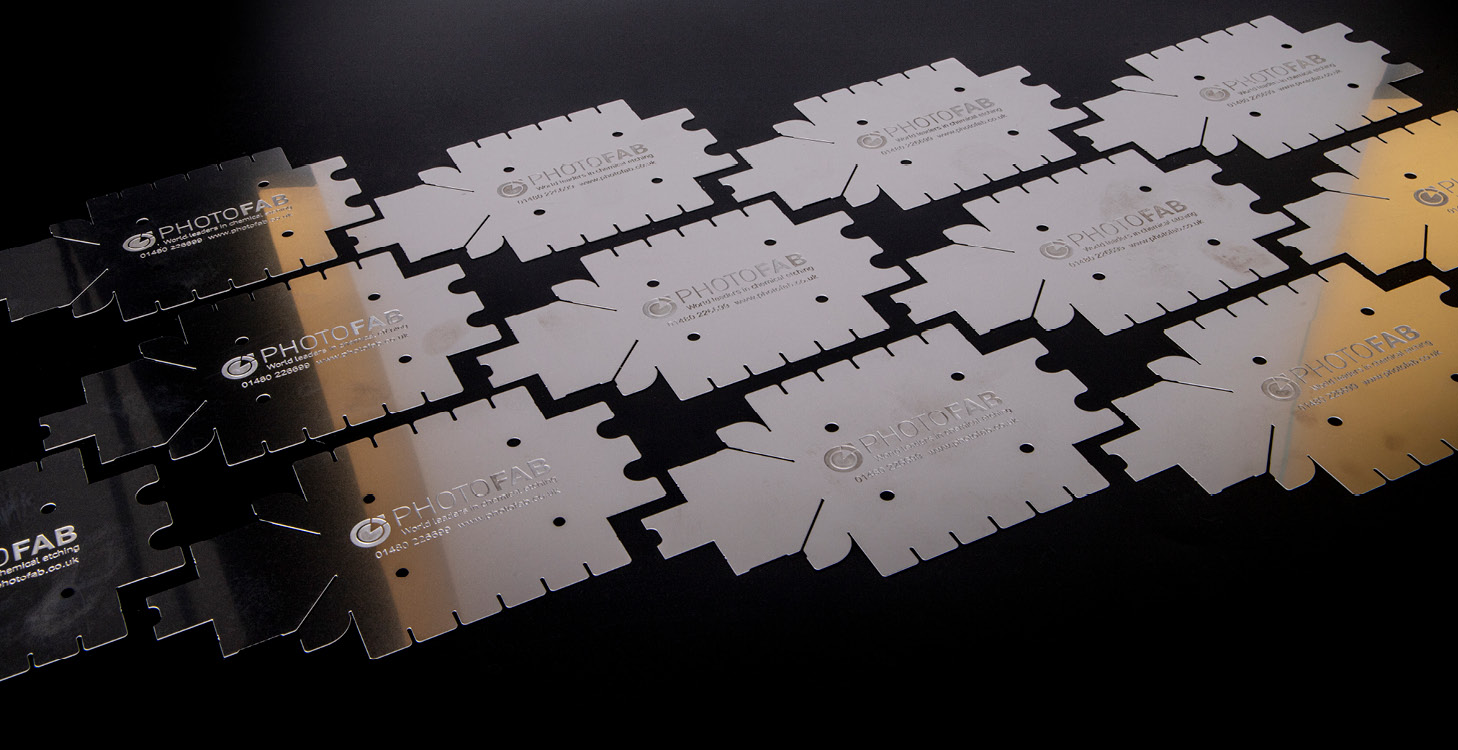

Delivering at ever-smaller sizes

Electronics components continue to shrink in size, as performance demands and efficiencies rise. Smart engineering fits more functionality into less space. We help meet the need for fast precision manufacturing with chemical etching across various metals. This includes steel, stainless steel, aluminium, copper alloys, and nickel alloys. We provide the consistency and tolerances needed for miniature electronics. Etching is the perfect process due to the extreme precision it can deliver, even on microscopic scales.

The advantages

Decades of experience and industry-leading customer service make us the choice of partner for so many. Our investments in people, technology, and processes drive leading quality, rapid turnarounds, and competitive costs. Some of our key benefits include:

- 24/7 quoting and support from dedicated account managers

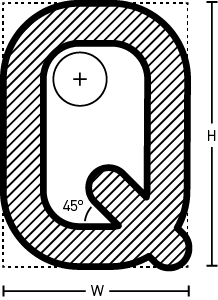

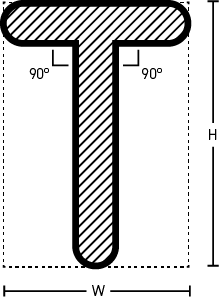

- Tool-free forming with etched fold lines

- Rapid 24-hour turnaround service

- Cost-saving stock tooling options

- Full supply chain management and technical expertise

- Quality management accredited to key ISO standards

Electronics innovation will shape the future across industries. Photofab provides their proven chemical etching expertise and capabilities to support customer success in this vital sector.

Power-up your next electronics project with us

One of the key reasons we enjoy high customer retention and longevity is the team of dedicated Account Managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire service. Why not prototype your next electronics project with us and see the Photofab difference for yourself! Contact us now or follow Photofab on LinkedIn for the latest updates.

What materials can be etched?

We offer an extensive range of metal types and thicknesses, all with full traceability. Various hardness are also offered to meet your requirements. Metal stocks are kept at levels that enable Photofab to offer rapid service to meet the needs of this fact paced industry.

Stainless Steels

Austenitic (301, 302, 304, 316, S526, S527), Martensitic (321, 410, 420), Precipitation Hardened (17/7), Heat Resisting (309, 310)

Other Steels

Mild Steel, Carbon Steel, Tool Steel, Spring Steel, Transil, Losil.

Nickel Alloys

Nichrome, Mu Metal, Nickel Copper (70/30), Inconel, Nickel Brazing Foil.

Nickel/Iron Alloys

Invar, Alloy 42, Kovar, Radio Metal.

Copper

Tough Pitch 101, Oxygen free – High Conductivity.

Copper Alloys

Brass, Phosphor Bronze, Beryllium Copper, Nickel Silver, Ferry Constantan.

Aluminium and Aluminium Alloys

Silver and Alloys

Silver, Silver Alloys, Silver/Copper, Silver/Palladium, Silver Brazing Alloys.

Why work with us?

We are renowned for their industry leading customer service, where our dedicated account managers are your expert single point of contact. Supporting you with anything from technical and design questions through to quotes, orders, delivery, and everything in between. We strive to offer the best customer service experience in the industry. We take immense pride in being able to push the boundaries of chemical etching with our commitment to continuous improvement.

KNOWLEDGE

Over 55 years of expertise and experience with a highly trained team of specialists delivering high volume orders.

CAPACITY & SPEED

For cost-effective full volume orders of hundreds of thousands. We also offer fast turn-around, as little as 24 hours.

SERVICE

Our dedicated account managers are experts and there to help, advise and manage.

RELIABILITY

Trusted by thousands of OEMs to deliver quickly and accurately.

QUALITY

SC21, ISO 9001, 14001 & 45001 quality processes.

TRACEABILITY

Fully traceable materials and processes.

To find out how we can help you