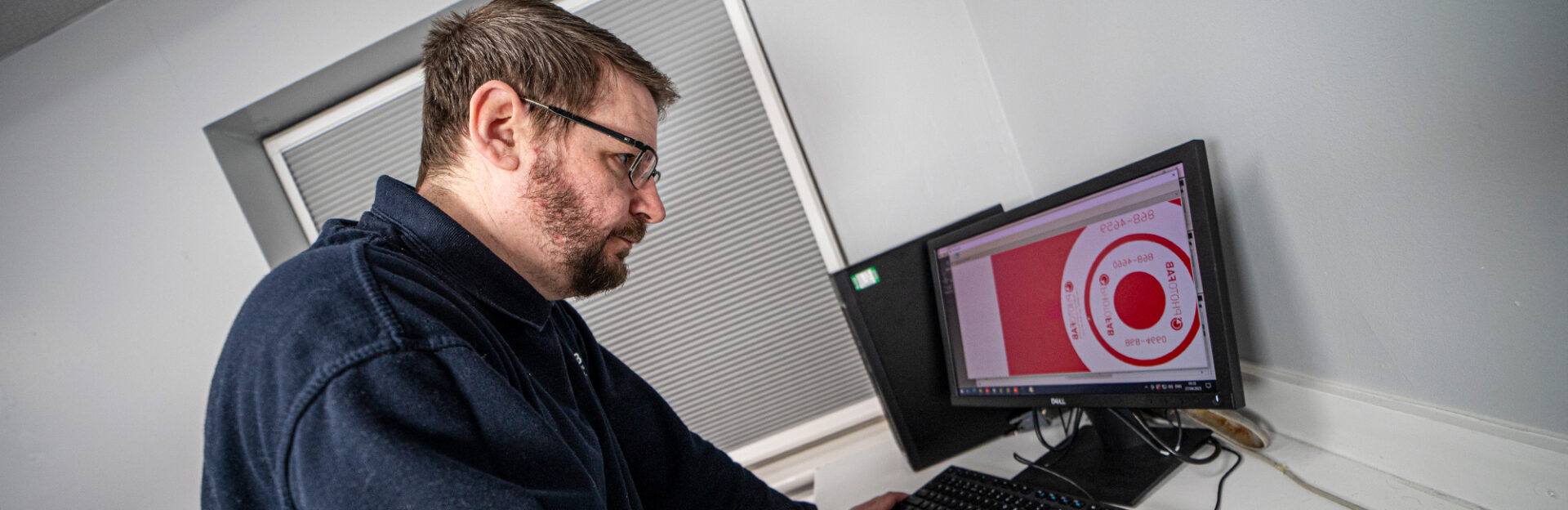

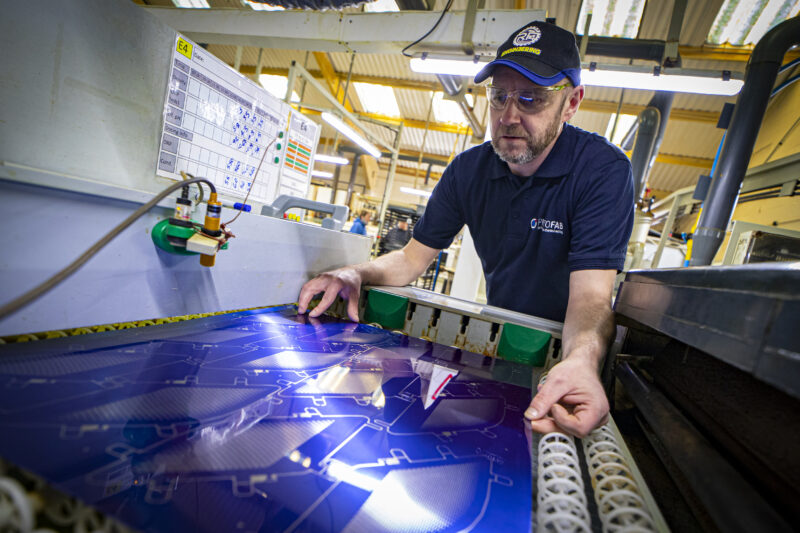

We have been at the cutting edge of components manufacturing for over 55 years. We have seen a lot of change in our long history as a company. Digital files have now become an essential part of our tooling process – digital tooling gives a huge flexibility of design, while allowing our team to easily review and edit designs. Digital tooling dramatically speeds up the tooling process for a fraction of hard tooling cost. The other benefits of this service are significant, with quick and easy changes to specifications, faster lead-times, and multi-component designs all on one sheet.

Our experienced team have been using digital tooling for decades and can be relied on to bring your designs to life at our state-of-the-art facility. With ISO 9001 certification, you don’t have to take our word for it. Our commitment to quality is recognised.

For more information on how we can reduce your costs & improve lead time contact our dedicated account managers on 01480 226699 or email enquiries@photofab.co.uk.

MAXIMUM Flexibility

While some manufacturers insist on a specific file type to work with their design tools, our customer-led process means we are comfortable working with all drawing file types. This gives our customers the maximum flexibility in their designs – you design it how you like; we tool it. Our team of experts will work with you to ensure your files can work in our system and produce working tools. We go by the saying: “If you can draw it, we can make it in thin sheet metal.”

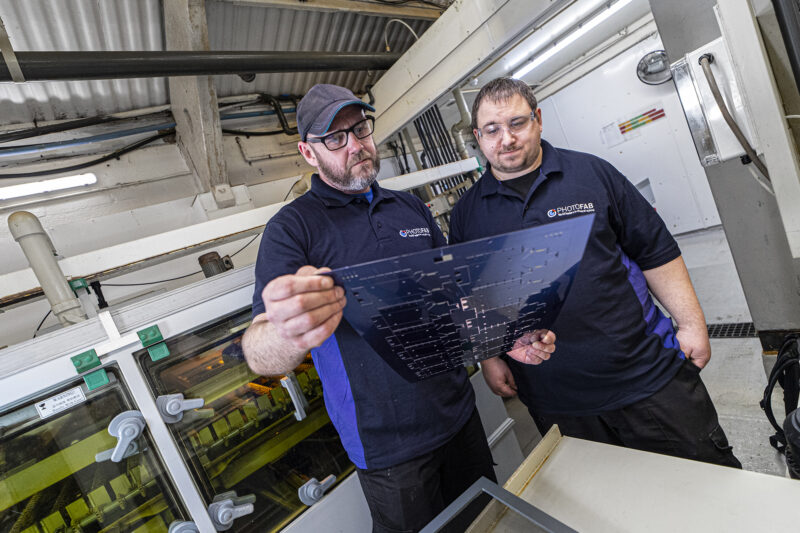

We offer a complete solution, from design and prototype to full production. Before we can be involved in the development of new products, we undertake a stringent design process by which specifications for component prototypes are carefully conceived. This ensures from the outset that your products are fit for purpose once they are in production. We will work with your designs to create viable products and have the capabilities to scale up to full volume production, no matter the process.

Examples of file types we can work with:

CAD Files

.dwg

.dxf

.IGES

.STP

Image Files

.pdf

.eps

.cdr

.ai

If your file format is not any of the ones listed above, please reach out to us so we can discuss and help understand your requirements further. We’re confident we can come to a solution that allows us to manufacture based on your designs.

Manufacturing and Beyond

When we start the manufacturing process, we prefer CAD files in the format .dwg, .dxf and .IGES, but we can also use image files such as those listed above. This means no matter what design tools you use; the team at Photofab can bring them to reality.

Our expert team has a long history of delivering outstanding parts based on our customers designs. With options from prototyping all the way to high volume production, we are the manufacturing partner you’re looking for.

With over 55 years of experience in the industry, we can use your designs for all manner of order volumes, be it a single prototype or a very high-volume order – we pride ourselves on being able to deliver for our customers.

UPLOAD Straight to us

We offer the opportunity for you to upload your digital design files directly to us before receiving a quote – this allows us to review your design and assess what’s best for you during a quote. We can accept almost all file formats, so there is no need to hesitate – upload your tooling design below and one of our expert team will get back to you within 24 hours. When working with us, you will be assigned a dedicated account manager to handle all your queries and take charge of your order from the initial placement all the way through to delivery at your business.

DEDICATED engineering

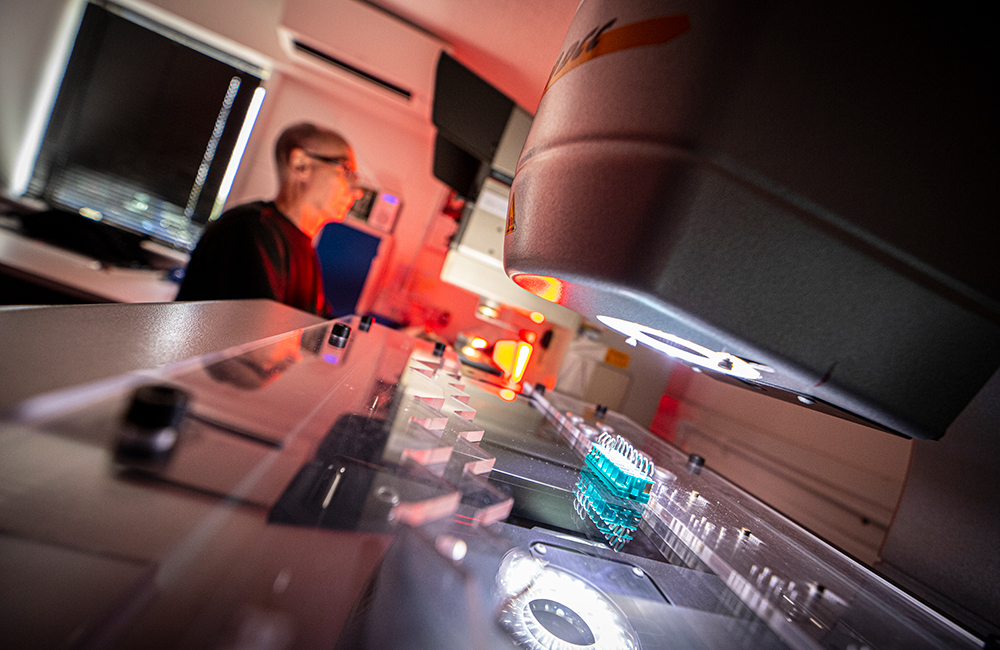

We understand the importance of skilled engineering when designing components and putting them into production. Therefore, we have heavily invested in a dedicated secondary engineering unit, the aim of this is to offer an even greater service and flexibility to our customers.

Originally set up to provide an in-house solution to support the etching division, it has proven so popular with our customers that we are now offering toolroom, forming and finishing as stand-alone services. This means our customers now have access to a new level of flexibility – enjoying the convenience of full-service manufacture or pick and choose services to suit them. It truly is a complete service we offer.

We continue to offer cutting-edge services and outstanding lead times, and we can do so because of continuous investment in our people and our processes, leading to class-leading output and lead times – including our rapid 24 hour turnaround service.

The benefits of

working with us

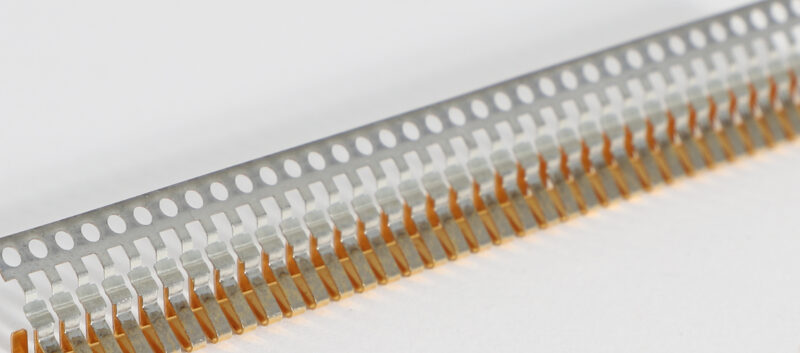

We are world leaders in the development of photochemical technology to produce intricately shaped components. We have produced over 80,000 different components over the years and are highly regarded for our chemical etching process. Our engineers offer many services that you can find here, and will offer advice to improve the product and reduce the costs.

24-hour quotation service

Dedicated account managers

Rapid manufacturing service

Cost saving stock of uni-tooling

Etched fold lines for tool-free forming

Full manufacturing service and supply chain management

Access to manufacturing and technical advice and expertise

Quality accredited to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze

The key difference

One of the key reasons we achieve high levels of customer retention and longevity is the team of dedicated account managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire service.

Customers rely on their dedicated contacts’ understanding and in-depth knowledge of their specific requirements and know the highest standards will always be met using the most efficient and cost-effective methods.

This consistent service is the foundation of our customer loyalty and is maintained throughout every department and every stage of production. Put us to the test for your next project and call one of our account managers on 01480 226699 or use our customer enquiry form.

Value added partnerships

We also have long working relationships with specialist partners for additional finishing services. These services can range from laser-cutting, plating, anodising and heat treatments which can add decorative finishes, prevent corrosion, and further improve durability.

All additional processes are managed closely and delivered with full transparency and traceability.

start your production journey today

If you are looking to find a complete service include dedicated engineering to design and implement your solution, get in touch with us. You’ll be given an account manager who is always on hand to advise and take care of everything for you. Call us on 01480 226699 or contact us now to see how we can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn.

TAKE A LOOK AT OTHER

SERVICES we offer

To find out how we can help you

Get in touch today