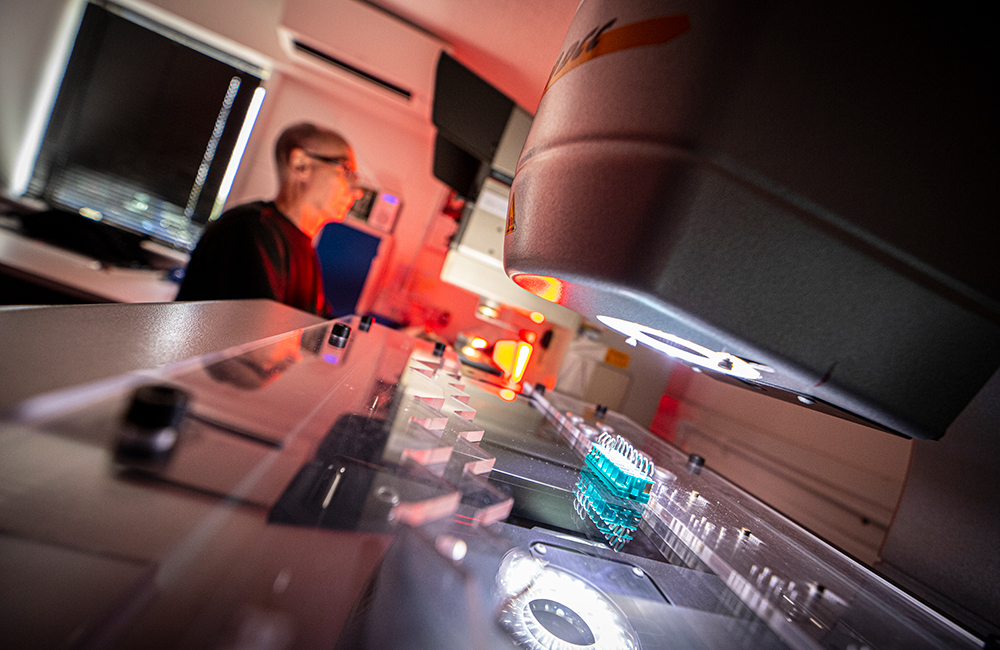

We are well-renowned for their world class Chemical Etching service, from prototyping to large volume orders. To ensure our commitment to providing the most cost-effective service for our customers; for exceptionally high-volume orders, we offer the option of utilising our strong relationship with a quality manufacturing partner in the Far East. This outsourcing service is still managed in-house with the same care and quality standards as our own manufacturing service, this reassurance allows for quality production at a more cost-effective rate.

We automatically recommend this option for very high-volume orders, where the most savings can be made. Our commitment to quality and service remains constant throughout – our supplier has been tried and tested by ourselves and everything is handled by our experts at Photofab.

For more information on how we can reduce your costs & improve lead time contact our dedicated account managers on 01480 226699 or email enquiries@photofab.co.uk.

THE SAME GREAT SERVIce

By opting for this service, we can offer the same quality-controlled production at a far more cost-effective rate. We have carefully conducted research and site visits to ensure our partner passes all tests for environmental, ethical and employment practices. This means you can order with confidence, and every order is inspected, and quality assured by us.

If for any reason your order cannot be completed or is delayed, we will – at no extra charge – complete your order at our UK facilities. That’s why you can order with complete confidence. Our Far East supply chain is the perfect solution for high volume chemical etching. We take complete control of the entire process, meaning the only difference you see is the cost!

Why Use Our Far East Supplier Service?

A reputable and reliable partner, where the same high standards are assured.

The service is backed up by our facilities in the UK, meaning you can buy with total confidence.

Shipping costs and delivery times are minimised as parts are small and light and can therefore be sent by air.

Dedicated supply chain management means we handle every aspect of the order and deliver it to you.

Fully inspected and quality assured by us before being sent on to your business, ensuring quality is at the same level as our own service.

A Dedicated account manager will be on hand to work with you and handle your order and any enquiries – part of our commitment to first class service.

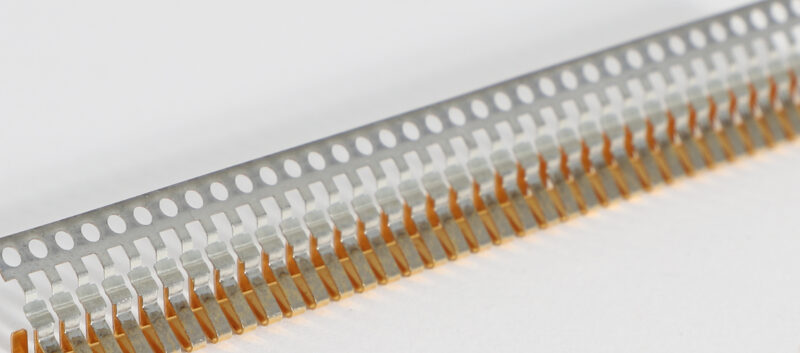

Whatever The Metal…

We can offer the same range of materials as our own Chemical Etching service. Our wide range of metals available for high volume chemical etching is as follows:

Stainless Steels

Austenitic (301, 302, 304, 316, S526, S527), Martensitic (321, 410, 420), Precipitation Hardened (17/7), Heat Resisting (309, 310)

Other Steels

Mild Steel, Carbon Steel, Tool Steel, Spring Steel, Transil, Losil.

Nickel Alloys

Nichrome, Mu Metal, Nickel Copper (70/30), Inconel, Nickel Brazing Foil.

Nickel/Iron Alloys

Invar, Alloy 42, Kovar, Radio Metal.

Copper

Tough Pitch 101, Oxygen free – High Conductivity.

Copper Alloys

Brass, Phosphor Bronze, Beryllium Copper, Nickel Silver, Ferry Constantan.

Aluminium and Aluminium Alloys

Silver and Alloys

Silver, Silver Alloys, Silver/Copper, Silver/Palladium, Silver Brazing Alloys.

Customer Testimonials

You don’t just have to take our word for it – the following testimonials are from genuine, satisfied, Photofab customers who have used our Far East Supply Chain Service.

I was sceptical at first, but the quality is fantastic.

G Cranston

Having Photofab’s UK facility as a backup encouraged me to try the Far East route, and I have not been let down.

L Pritchard

You can read more testimonials on our Net Promoter Score page.

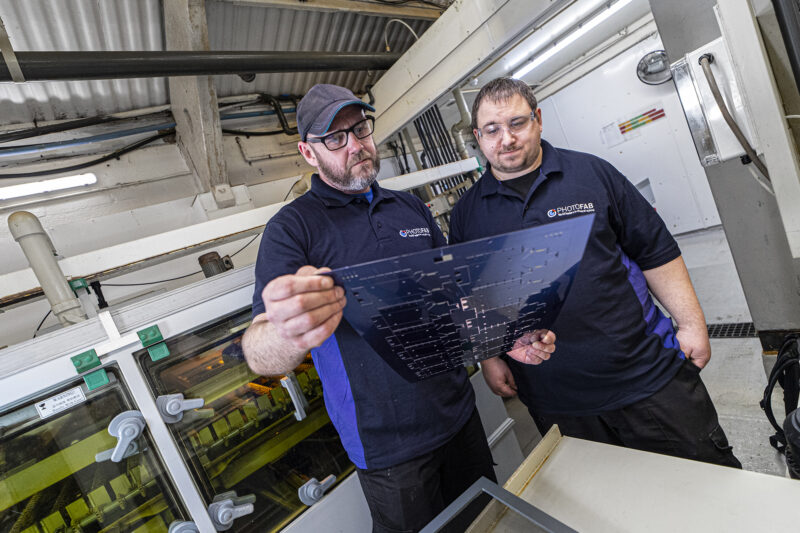

DEDICATED engineering

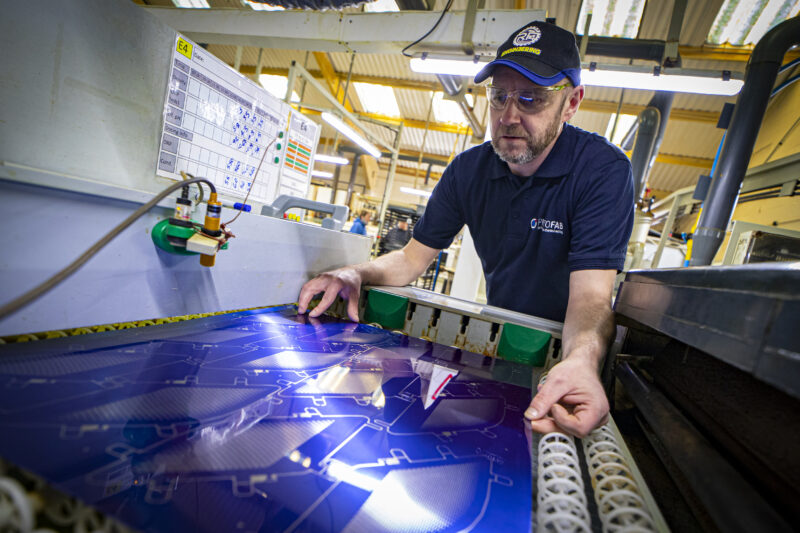

We understand the importance of skilled engineering when designing components and putting them into production. Therefore, we have heavily invested in a dedicated secondary engineering unit, the aim of this is to offer an even greater service and flexibility to our customers.

Originally set up to provide an in-house solution to support the etching division, it has proven so popular with our customers that we are now offering toolroom, forming and finishing as stand-alone services. This means our customers now have access to a new level of flexibility – enjoying the convenience of full-service manufacture or pick and choose services to suit them. It truly is a complete service.

We continue to offer cutting-edge services and outstanding lead times, and we can do so because of continuous investment in our people and our processes, leading to class-leading output and lead times – including our rapid 24 hour turnaround service.

The benefits of

working with us

We are world leaders in the development of photochemical technology to produce intricately shaped components. We have produced over 80,000 different components over the years and are highly regarded for our chemical etching process. Our engineers offer many services that you can find here, and will offer advice to improve the product and reduce the costs.

24-hour quotation service

Dedicated account managers

Rapid manufacturing service

Cost saving stock of uni-tooling

Etched fold lines for tool-free forming

Full manufacturing service and supply chain management

Access to manufacturing and technical advice and expertise

Quality accredited to ISO 9001, ISO 14001, ISO 45001 and SC21 Bronze

The key difference

One of the key reasons we enjoy our customer retention and longevity is the team of dedicated account managers. This ‘single point of contact’ throughout the whole process, ensures a personal service, and pride in the quality and reliability of the entire Photofab service.

Customers rely on their dedicated contacts’ understanding and in-depth knowledge of their specific requirements and know the highest standards will always be met using the most efficient and cost-effective methods.

This consistent service is the foundation of our customer loyalty and is maintained throughout every department and every stage of production. Put us to the test for your next project and call one of our account managers on 01480 226699 or use our customer enquiry form.

Value added partnerships

We also have long working relationships with specialist partners for additional finishing services. These services can range from laser-cutting, plating, anodising and heat treatments which can add decorative finishes, prevent corrosion, and further improve durability.

All additional processes are managed closely and delivered with full transparency and traceability.

start your production journey today

If you are looking to find a complete service include dedicated engineering to design and implement your solution, get in touch with us. You’ll be given an account manager who is always on hand to advise and take care of everything for you. Call us on 01480 226699 or contact us now to see how we can add an extra dimension to your manufacturing project. Keep up to date by following us on LinkedIn and Twitter.

TAKE A LOOK AT OTHER

SERVICES we offer

To find out how we can help you

Get in touch today