ON FORM TO SHAPE AN OUTSTANDING SERVICE

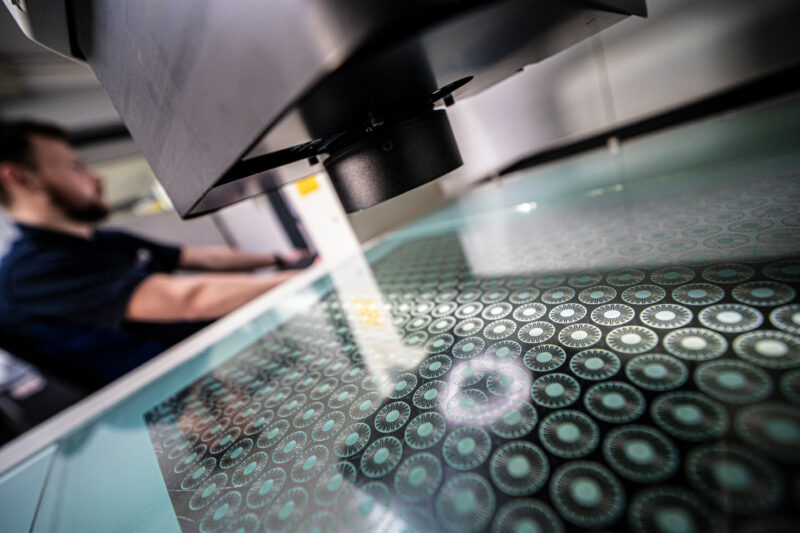

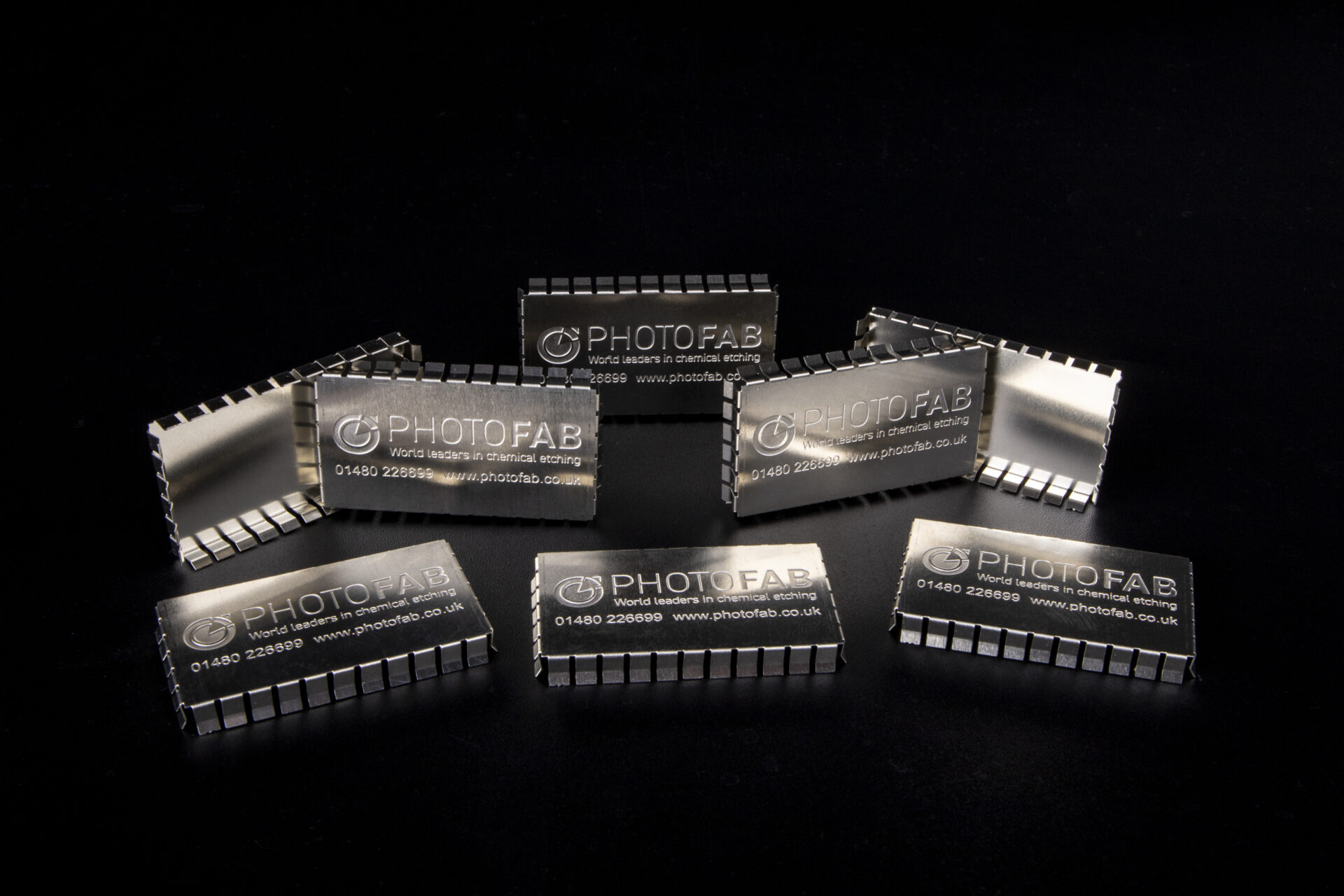

With decades of experience in the production of tooling for sheet metal forming, which has been instrumental in supporting our globally renowned chemical etching capabilities, we are already well established in the industry for quality hard tooling. Recognising the significance of this process in the manufacturing journey, we made substantial investments in a specialised secondary unit.

Initially established as an in-house solution to complement the etching division, the toolroom has demonstrated remarkable success. Consequently, we now offer toolroom, forming and finishing as stand-alone services that enhance our service offerings and provide greater flexibility to our valued customers, who can either utilise our comprehensive full-service manufacturing solutions or select specific services that align with their unique requirements. With capabilities to produce precise and intricate components, we can turn ideas into reality faster than ever before.

Tailor Made Innovations.

Expanding into forming and finishing as independent services was a natural progression, and we were fortunate to have highly experienced engineers on hand to ensure that these new offerings would complement the renowned standards of our etching division.

In addition to our extensive inventory of hundreds of stock universal tooling and custom tooling capabilities, our team developed a custom multi-slide tool for specialist curvature forming. This innovation is supported by a team of highly skilled metal formers, 40 presses, and the recent addition of an SP30 to our machinery lineup. With this expanded capacity, we can now process sheet metal up to 6mm thick and 500mm wide, providing an exceptionally diverse range of capabilities to meet our customers’ needs.

Achieving the Perfect Balance: Speed and Quality United.

We firmly believe that speed and quality are not mutually exclusive. Our processes strictly adhere to SC21, ISO9001, 14001, and 45001 standards, ensuring full traceability throughout every stage of production. This commitment to quality is seamlessly integrated with our focus on manufacturing efficiencies and automation, allowing us to provide our customers with the best of both worlds.

From rapid prototyping of small batches to fulfilling high-volume orders in as little as three days, our streamlined processes and exceptional 98% on-time delivery rate are designed to surpass your expectations. We are dedicated to delivering both speed and quality, enabling you to bring your products to market efficiently without compromising on excellence.

A Comprehensive Suite of Services.

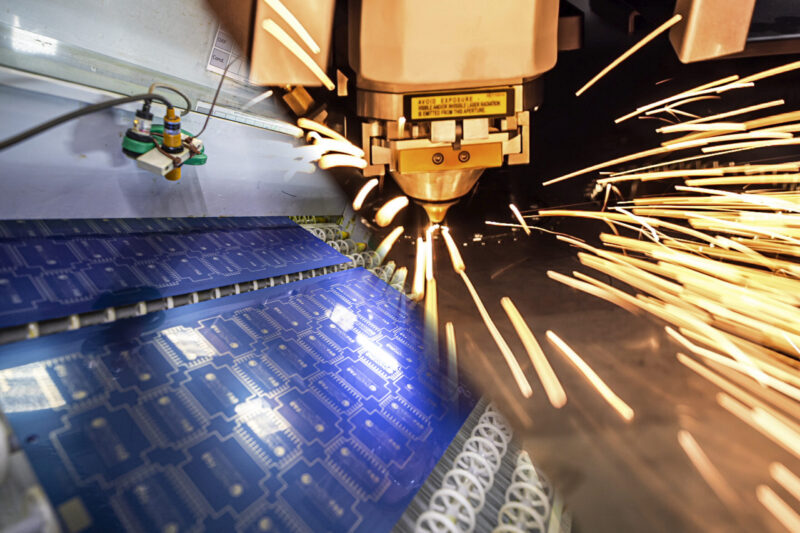

We have cultivated long-standing partnerships with specialised providers to offer a comprehensive range of additional finishing services, including laser cutting, plating, anodising, and heat treatments. These strategic alliances enable us to provide a one-stop solution for our customers, ensuring that all additional processes are meticulously managed and delivered with full transparency and traceability.

Experience The difference.

We are committed to providing exceptional service and delivering tailored solutions that exceed your expectations. Our expertise in chemical etching, coupled with our extensive network of specialist partners, allows us to offer a comprehensive suite of services that cater to your every need. To find out how we can elevate your prototyping or precision manufacturing project, connect with our dedicated team of account managers today. Alternatively, reach out to us directly to discuss your unique requirements.

Call one of our dedicated team of account manager’s today or contact us now to see how we can add an extra dimension to your prototyping or precision manufacturing project. Keep up to date by following us on LinkedIn.